Hydraulic oscillator used under oil field well

A technology for hydraulic oscillators and oilfield wells, used in vibration drilling, wellbore/well components, vibration generating devices, etc., can solve the problems of limited vibration impact momentum, large hydraulic pressure drop, and high cost, and achieve vibration frequency and impact. The effect of large momentum range, high kinetic energy conversion efficiency and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

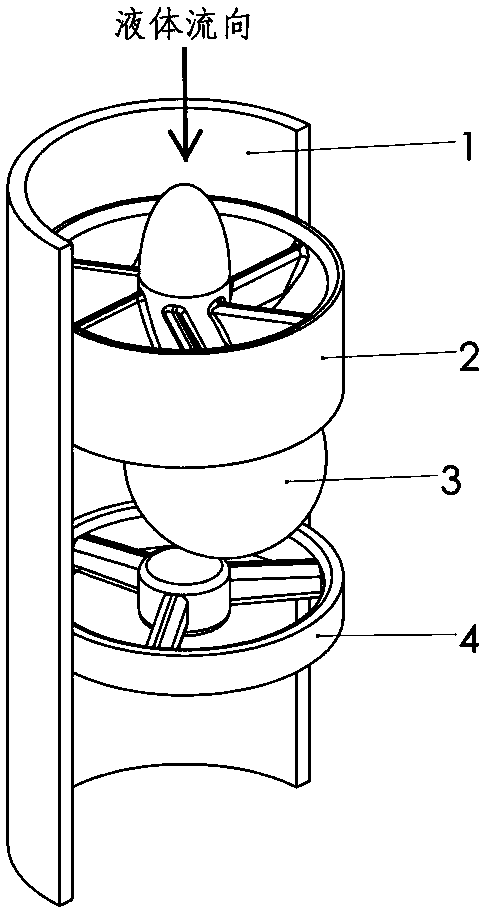

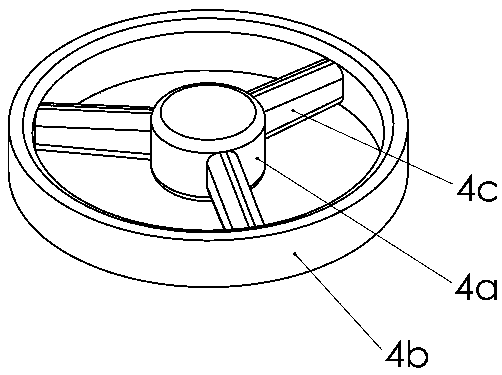

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, several examples are described below. The main component parameters in the embodiment: the pipeline 1 is a 5-1 / 2 inch oil casing with an inner diameter of 125.7 mm; the solid ball 3 is a chrome-plated steel ball with a diameter of 80 mm.

[0018] as attached figure 1 As shown, the liquid flows into the circular pipe 1 from the direction indicated by the arrow in the figure, and after passing through the vane plate 2 fixedly connected with the pipe, a swirling flow is formed, and the swirling flow drives the solid ball 3 to move in the circumferential direction. Due to the centrifugal force, the solid ball 3 The ball 3 rolls and revolves closely against the inner wall of the pipe 1 in the space between the guide vane disc 2 and the ball stopper 4, and exhibits radial vibration to the outside.

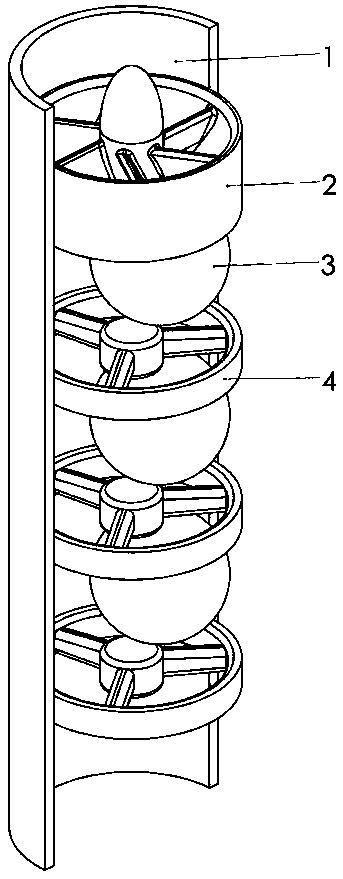

[0019] image 3 It is a structural schematic diagram of a mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com