PERC battery back pole slurry and preparation method thereof

A back electrode and slurry technology, which is applied in the field of PERC battery back electrode slurry and its preparation, can solve the problems of health threats to production workers, pollution of the workshop environment, unstable product formula, etc., and achieve improved formula stability and uniform particle size Sex, reduce adverse effects, improve the effect of formulation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

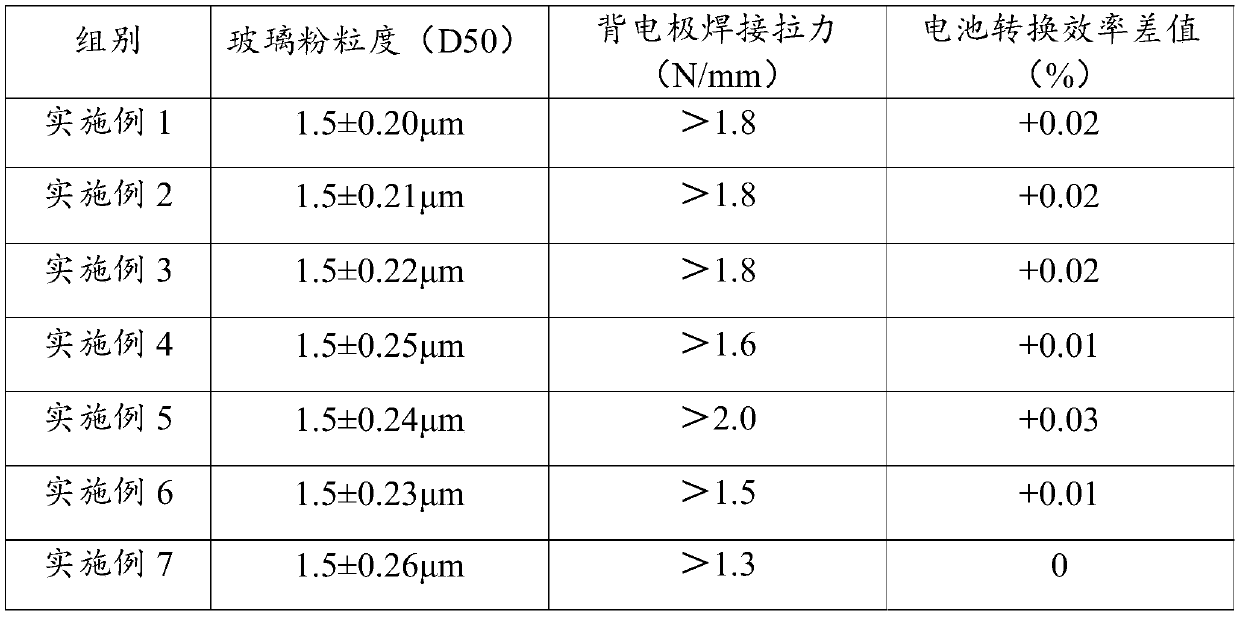

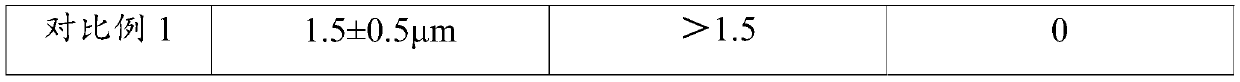

Examples

Embodiment 1

[0033] An embodiment of a PERC battery back electrode slurry of the present invention, the PERC battery back electrode slurry includes the following components in weight percentage: 50% silver powder, 10% conductive filler, 3% glass powder, organic binder Agent 37%.

[0034] The silver powder described in this embodiment adopts spherical silver powder; the particle size is 100nm-3μm.

[0035] Described conductive filler selects the mixture that mass ratio is 1:1 graphene and carbon nanotube;

[0036] The glass powder is formed by reacting tetraethyl orthosilicate, triethyl phosphate, boric acid, zinc acetate, calcium citrate, and barium acetate in absolute ethanol, wherein tetraethyl orthosilicate: triethyl phosphate : Boric acid: zinc acetate, calcium citrate: barium acetate molar ratio is 10:15:20:35:5:15;

[0037] The organic binder consists of 80 wt% solvent, 15 wt% thickener and 5 wt% additives. The solvent in this example is alcohol ester twelve, the thickener is ethy...

Embodiment 2

[0043] The only difference between this example and Example 1 is that the preparation method of the PERC battery back electrode slurry is different, and the preparation method includes the following steps:

[0044] 1) Preparation of glass powder: put tetraethyl orthosilicate, triethyl phosphate, boric acid, zinc acetate, calcium citrate and barium acetate in total 9.6kg into a 100L reaction kettle according to the above molar ratio, add 60L Absolute ethanol was used as the reaction medium, stirred evenly, acetic acid was added to adjust the pH value of the solution to 5, and the stirring was continued for 2 hours, then reacted and aged at room temperature for 3 days, and the supernatant liquid was separated to obtain glass slurry. Place the glass slurry in a vacuum oven at 60°C for 5 hours, and then pulverize it to obtain glass powder;

[0045] 2) Preparation of organic binder: put solvent, thickener and additives in the reaction kettle in proportion, stir and melt at 110°C to...

Embodiment 3

[0048] The only difference between this example and Example 1 is that the preparation method of the PERC battery back electrode slurry is different, and the preparation method includes the following steps:

[0049] 1) Preparation of glass powder: 8 kg of tetraethyl orthosilicate, triethyl phosphate, boric acid, zinc acetate, calcium citrate and barium acetate are put into a 100L reaction kettle according to the above molar ratio, and 60L of Water and ethanol were used as the reaction medium, stirred evenly, acetic acid was added to adjust the pH value of the solution to 6.5, and the stirring was continued for 1 hour, then reacted and aged at room temperature for 4 days, and the supernatant liquid was separated to obtain glass slurry. Place the glass slurry in a vacuum oven at 75°C for 4 hours, and then pulverize it to obtain glass powder;

[0050] 2) Preparation of organic binder: put solvent, thickener and additives in the reaction kettle in proportion, stir and melt at 120°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com