LED epitaxial layer with new-type PSS structure and preparation method thereof

An epitaxial layer, a new type of technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high dislocation density of GaN materials, improved product quality, lattice mismatch, etc., to improve the light extraction efficiency and increase the light extraction angle. , The effect of simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

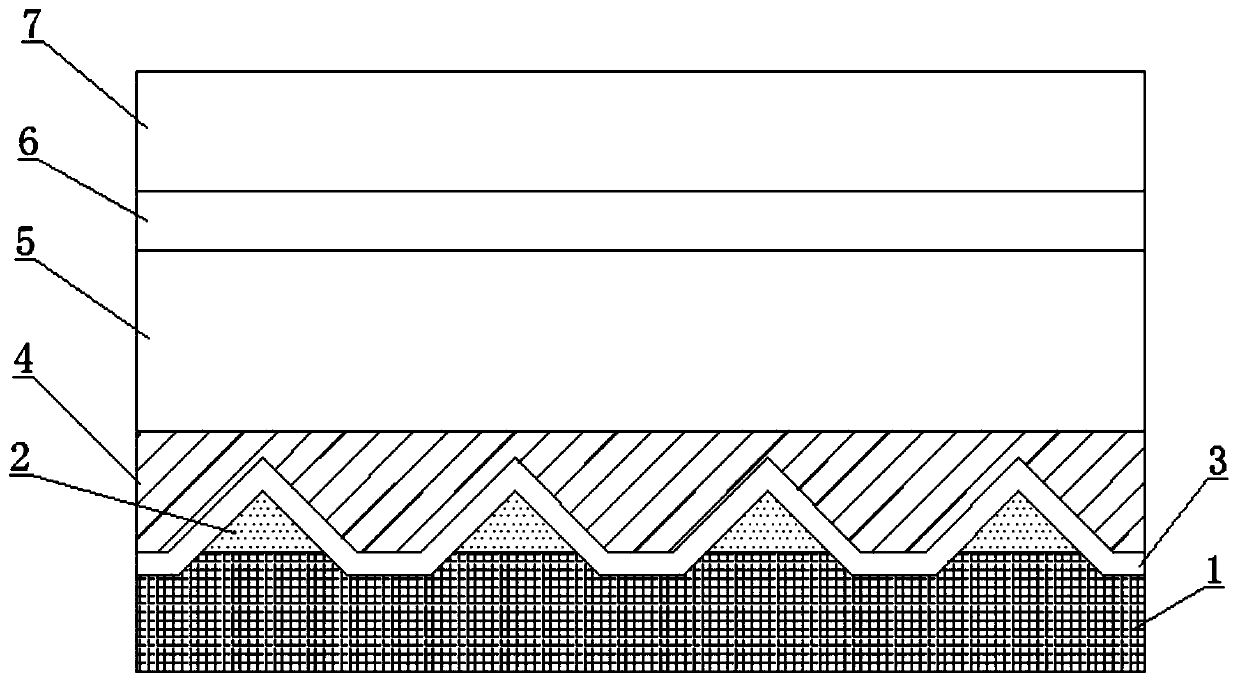

[0029] see Figure 1 ~ Figure 4 , a LED epitaxial layer with a new PSS structure, including a patterned substrate arranged in sequence along the axial direction, a U-type GaN layer 4 without Si doping, an N-type GaN layer 5 doped with Si, and an MQW active layer 6 and a p-type GaN layer 7 .

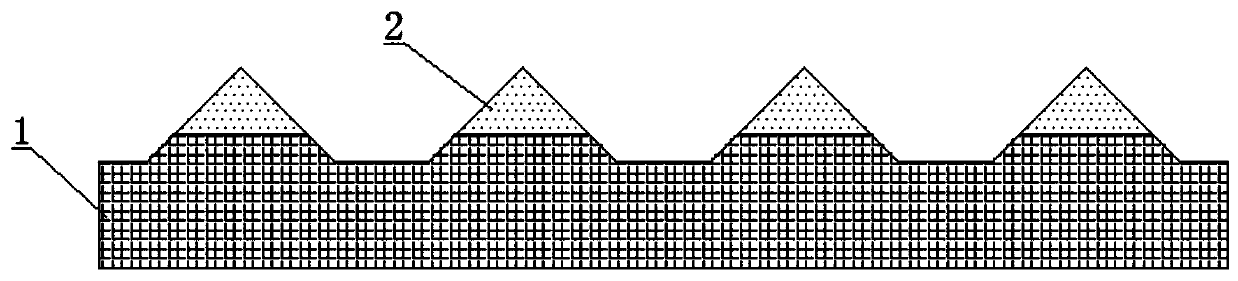

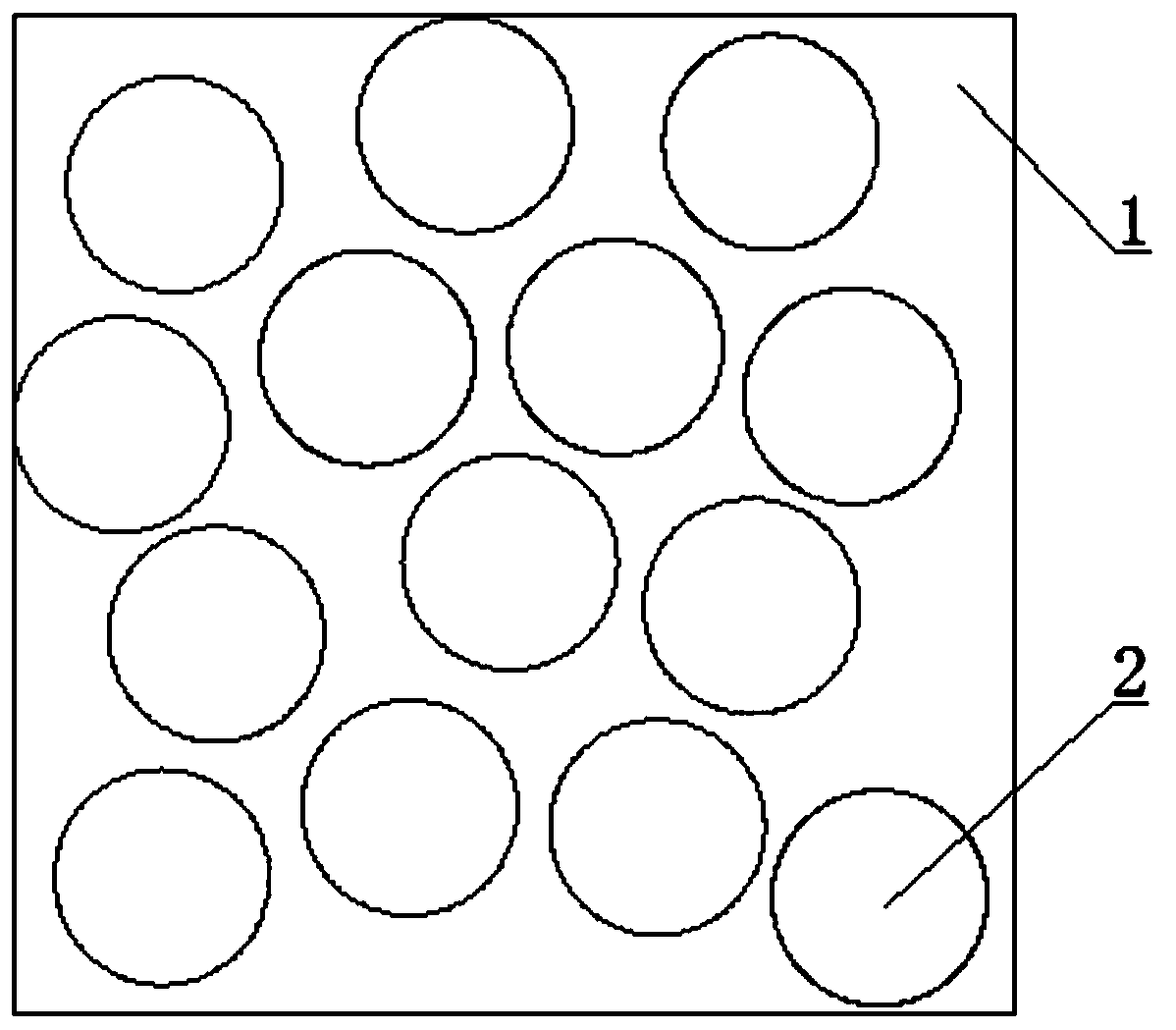

[0030] The patterned substrate includes a substrate material 1 and a substrate pattern arranged on the substrate material 1, the substrate pattern is a cone uniformly arranged in an array, and the cone includes a PSS film arranged up and down Projection structure of layer 2 and substrate material 1.

[0031] In this embodiment, the material of the substrate material 1 is sapphire, and the material of the PSS film layer 2 is silicon oxide.

[0032] In this embodiment, a layer of aluminum nitride film 3 is further provided between the patterned substrate and the U-shaped GaN layer 4, and the thickness of the aluminum nitride film 3 is 20 nm.

[0033] The preparation method of the LED epi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com