Full-inorganic LED packaging structure and preparation method thereof

A technology of LED packaging and LED chips, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of easy ventilation and low reliability of LED devices, and achieve the effects of stable chemical properties, good adhesion effect, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

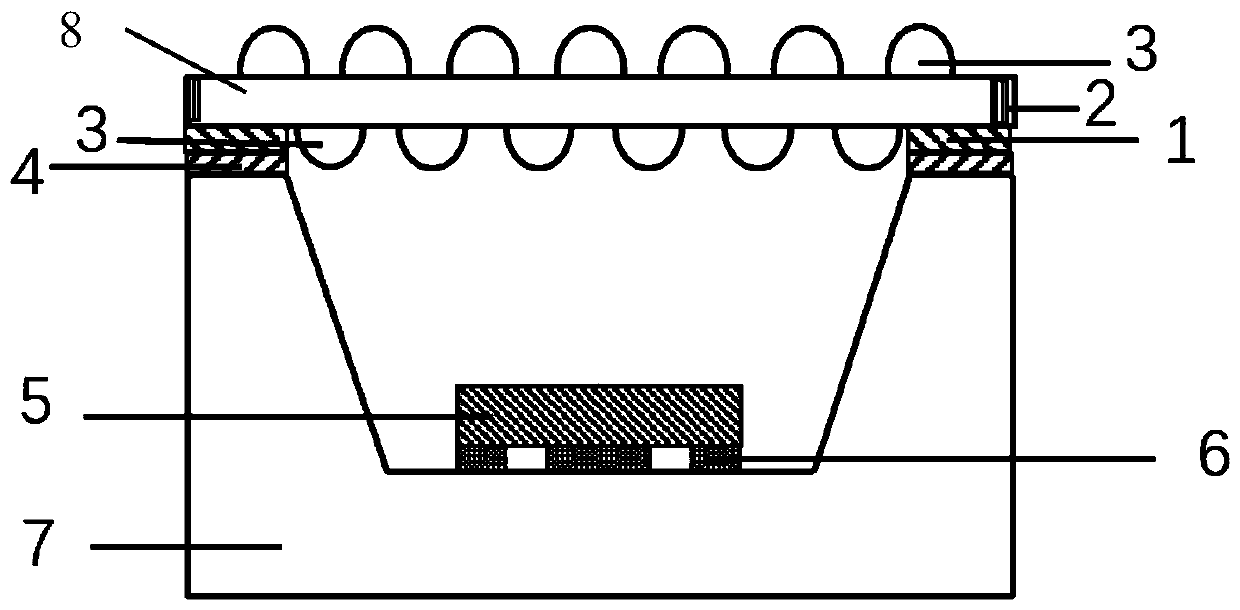

[0045] The present invention also provides a method for preparing the above-mentioned all-inorganic LED packaging structure, which includes the following steps:

[0046] LED chip bonding: bonding the LED chip 5 inside the dam-type copper-clad ceramic substrate 7;

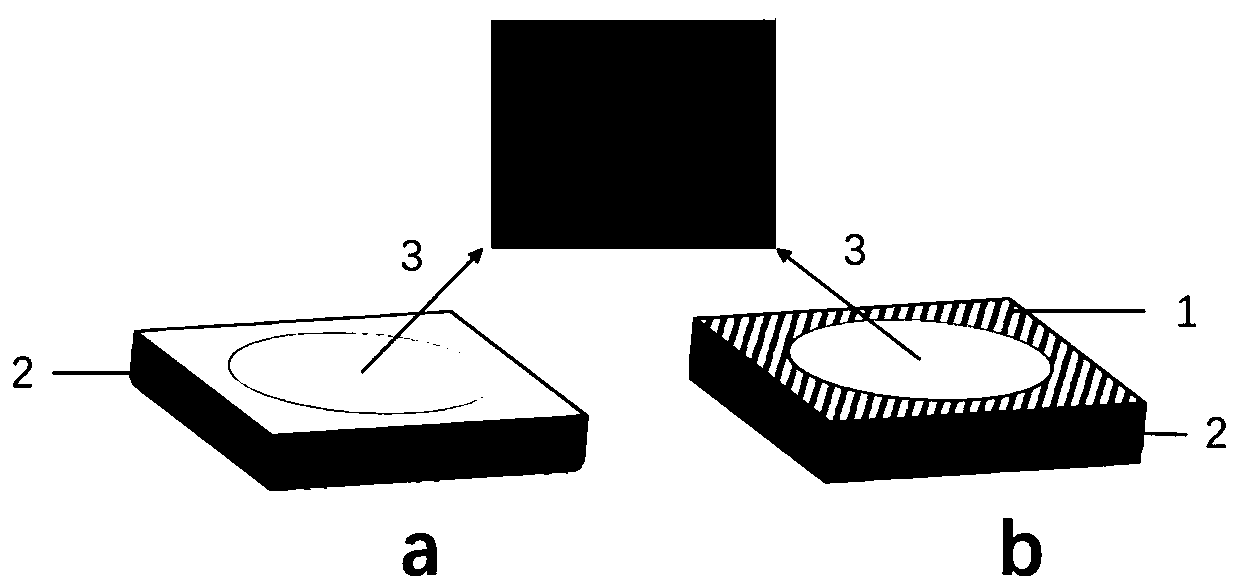

[0047] Preparation of the first metal layer: the first metal layer 1 is vapor-deposited on the area where the lower surface of the flat quartz glass 8 is in contact with the copper-clad ceramic substrate 7 by electron beam evaporation.

[0048] Complete the LED packaging: cover the flat quartz glass 8 with the first metal layer 1 on the copper-clad ceramic substrate 7 and put it into the reflow furnace for soldering and bonding.

[0049] The preparation method of the all-inorganic LED packaging structure of the present invention is simple and ensures the reliability of LED device packaging. And it is worth mentioning that the quartz glass metallization involved in the present invention can not only be used for deep ultravio...

Embodiment 1

[0059] LED chip solid crystal:

[0060] The LED chip 5 is passed through the second bonding layer 6 (solder paste) in a reflow furnace through five temperature zones to reflow and change, the highest temperature is 270 ℃, so that the chip and the copper-clad ceramic substrate 7 electrothermal separation area form a good bond, thereby The LED chip 5 is packaged inside a dam-type copper-clad ceramic substrate 7.

[0061] Prepare the first metal layer:

[0062] First, the corresponding metal light window layout is prepared according to the size of the copper-clad ceramic substrate 7. The size of the metal light window is 3.6mm×3.6mm, and the diameter of the middle circle is 3.04mm. The size of a metal layer 1 is the area excluding the circle, and this area is the pattern of the metal light window.

[0063] 1. Make the first metal layer on the flat quartz glass.

[0064] 1.1 Cleaning the sample: soak a 2-inch flat quartz glass 8 in ultrasonically heated acetone for 5 minutes to remove org...

Embodiment 2

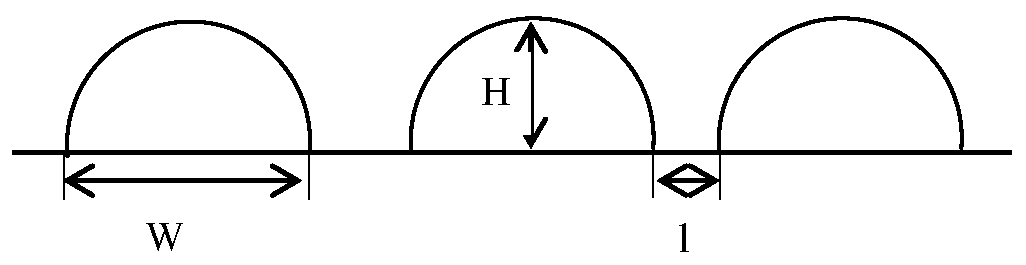

[0087] Embodiment 2 (a nano-microlens array is set on the upper surface)

[0088] Compared with embodiment 1, the difference of this embodiment 2 is that this embodiment only prepares the nano-microlens array on the upper surface of the flat quartz glass, and the other preparation methods are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com