Lithium-sulfur battery electrolyte and preparation method thereof

A lithium-sulfur battery and electrolyte technology, applied in the field of preparation of the electrolyte, can solve the problem that the improvement effect of battery specific capacity and cycle performance is not obvious, the improvement of cycle performance and specific capacity cannot be taken into account, it is difficult to industrialize production and Application and other issues, to achieve the effect of improving discharge specific capacity and cycle stability, improving discharge specific capacity and capacity retention rate, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The specific preparation method of embodiment 1 is as follows:

[0023] Step 1: In a glove box filled with argon gas, mix DOL and DME at a volume ratio of 1:1 to prepare a 100ml basic solution for lithium-sulfur batteries. The water content in the glove box is less than 0.1ppm , the oxygen content value is less than 0.1ppm;

[0024] Step 2: Mix 28.71 g of LiTFSI and 0.69 g of LiNO 3 After drying in a vacuum drying oven, slowly add it to 100ml of the basic solution, mix evenly to obtain the basic electrolyte of the lithium-sulfur battery, the vacuum degree in the drying oven is 10000Pa, the drying temperature is 120 degrees, and the drying time is 18 Hour;

[0025] Step 3: Add 0.24 g of C 8 h 18 Te 2 Slowly add to the basic electrolyte of lithium-sulfur batteries, and mix well to obtain the required lithium-sulfur battery electrolyte.

[0026] Step 4: Preparation of lithium-sulfur battery: Mix carbon-sulfur composite material, carbon black and polyvinylidene fluori...

Embodiment 2-7

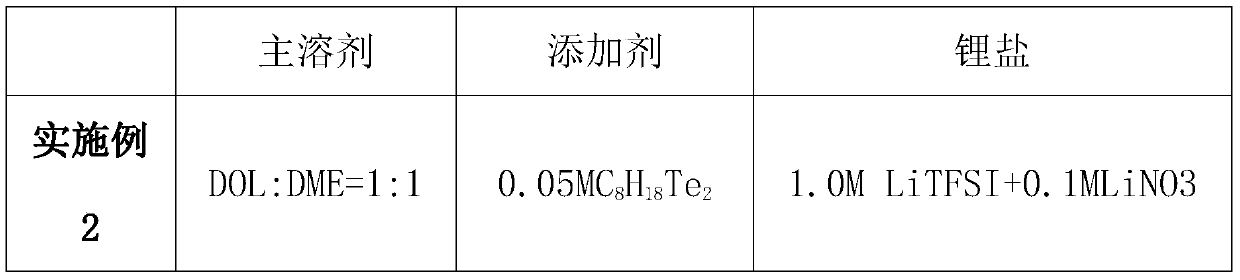

[0028] Except the parameters in the following table, other parameters and preparation method are the same as in Example 1.

[0029] Table 1 Embodiment 2-7 and Comparative Example 1

[0030]

[0031]

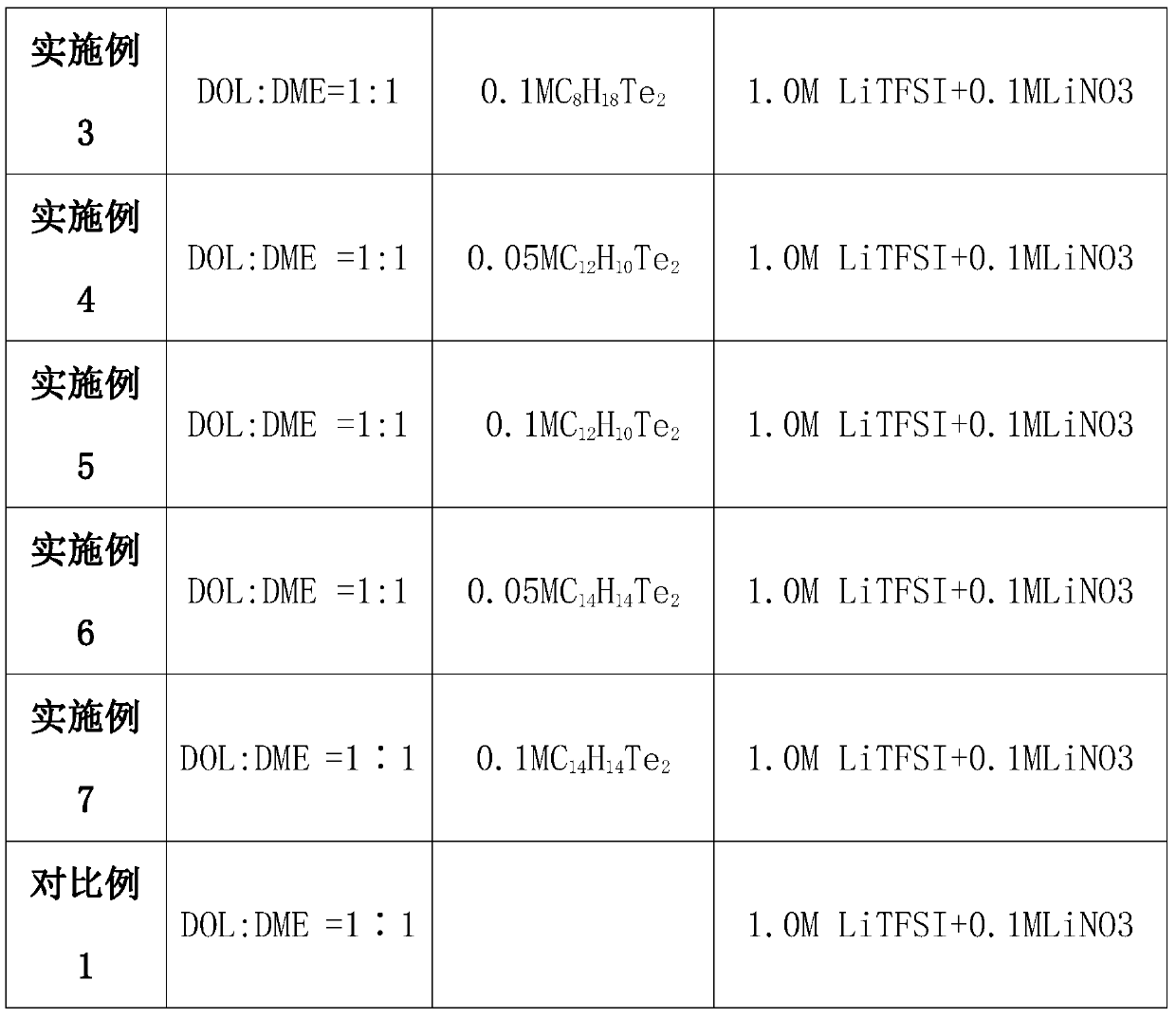

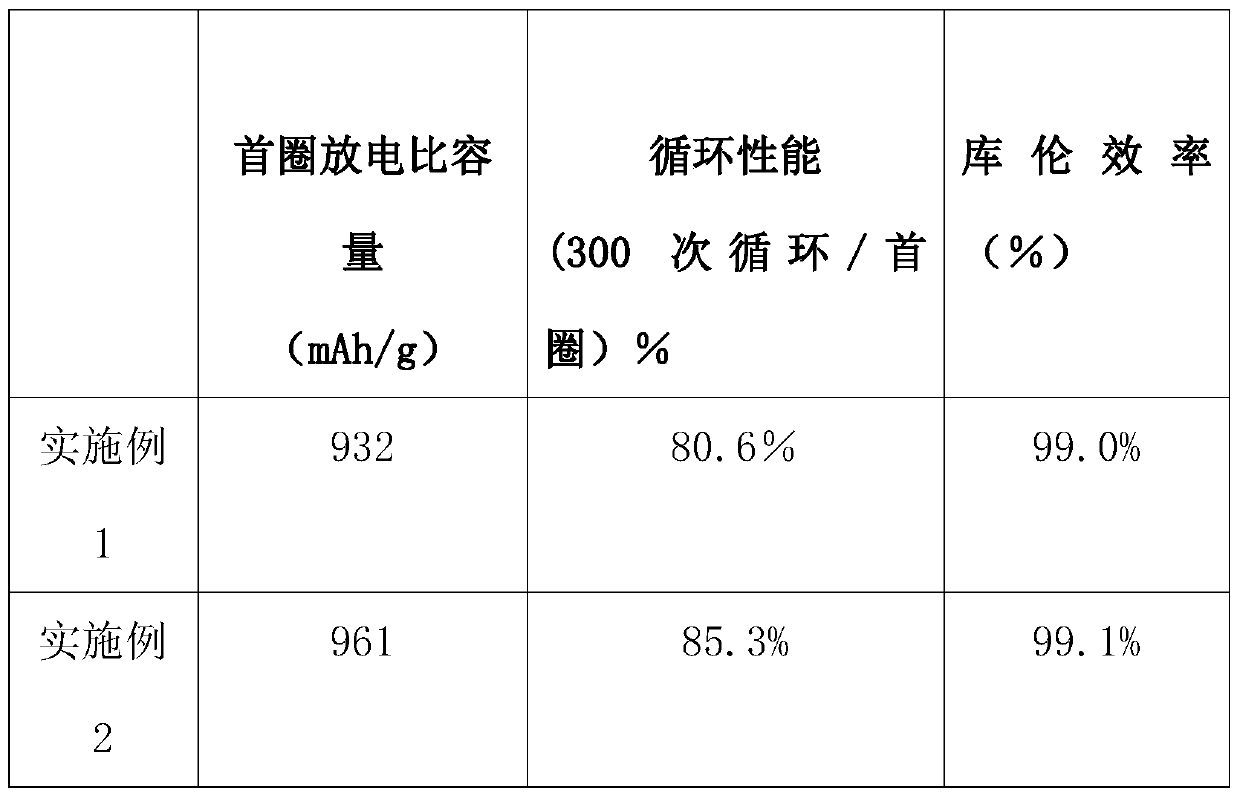

[0032] The test result under the 0.5C rate condition of table 2 embodiment and comparative example

[0033]

[0034]

[0035]From the results of Examples 1 to 7 and Comparative Example 1, it can be seen that in Comparative Example 1, at a discharge rate of 0.5C, the first cycle discharge specific capacity is 805mAh / g, which is less than the first cycle discharge specific capacity of Examples 1 to 7. 127mAh / g~208mAh / g. In terms of cycle performance, the capacity retention rate of Comparative Example 1 after 300 cycles is 31.6%, which is 49.0%-55.6% lower than that of Examples 1 to 7. It can be seen that the tellurium organic additives in the lithium-sulfur battery electrolyte can significantly improve the discharge specific capacity and cycle performance of the lithi...

Embodiment 8

[0037] The specific preparation method of embodiment 8 is as follows:

[0038] Step 1: In a glove box filled with argon gas, mix DOL, DME and DMDS according to the volume ratio of 1:1:1 to prepare 100ml of lithium-sulfur battery basic solution. The water content in the glove box is is less than 1ppm, the oxygen content value is less than 1ppm;

[0039] Step 2: Add 46.8 g of LiSO 3 CF 3 and 0.69 g of LiNO 3 After drying in a vacuum drying oven, slowly add it to 100ml of the basic solution, and mix well to obtain the basic electrolyte for lithium-sulfur batteries. The vacuum degree in the drying oven is 5000Pa, the drying temperature is 150 degrees, and the drying time is 12 hours. ;

[0040] Step 3: Add 4.8 grams of C 8 h 18 Te 2 Slowly add to the basic electrolyte of lithium-sulfur batteries, and mix well to obtain the required lithium-sulfur battery electrolyte.

[0041] Step 4: Preparation of lithium-sulfur battery: Mix carbon-sulfur composite material, carbon black ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com