A charging/heating control method for electric vehicle power battery

A power battery and heating control technology, applied in the direction of secondary battery charging/discharging, electric vehicles, battery/fuel cell control devices, etc., can solve the problems of battery damage and uneven heating temperature distribution, avoid overcharging, and realize heating And the effect of charging and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

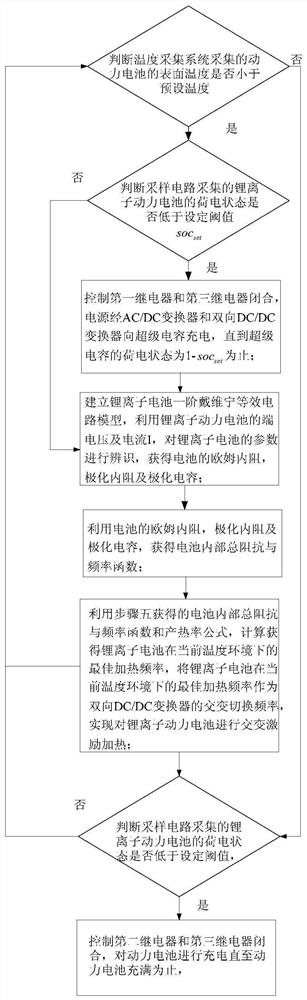

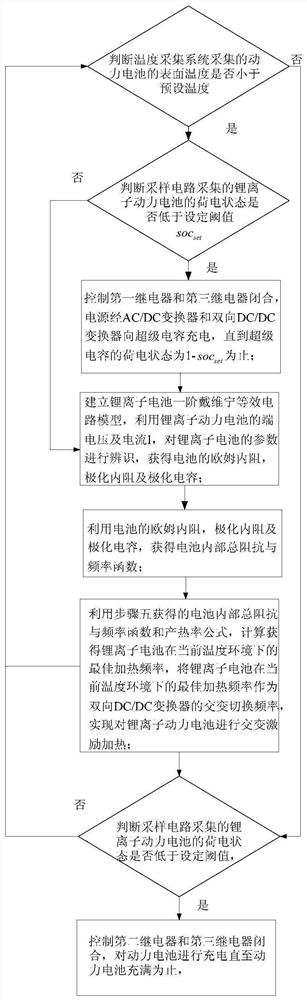

[0017] Specific implementation mode one: the following combination figure 1 Describe this implementation mode, a charging / heating control method for an electric vehicle power battery described in this implementation mode, the specific steps of the method are:

[0018] Step 1. Collect the surface temperature T of the lithium-ion power battery, and determine whether the surface temperature T of the lithium-ion power battery is less than the preset temperature threshold T set , if yes, go to step 2, otherwise, go to step 8; where, the temperature threshold T set is a positive number;

[0019] Step 2. Collect the state of charge soc, terminal voltage U and current I of the lithium-ion power battery, and determine whether the state of charge soc of the lithium-ion power battery is less than the set threshold soc set , if so, go to Step 3, otherwise, go to Step 4;

[0020] Step 3: Use an external power source to charge the supercapacitor until the state of charge of the supercapa...

specific Embodiment approach 2

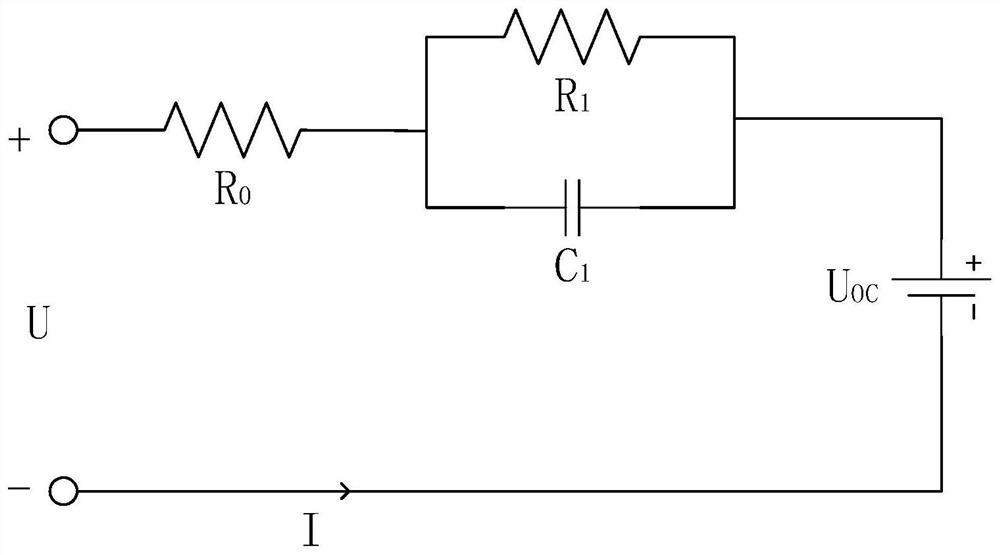

[0028] Specific implementation mode two: the following combination figure 2 Describe this embodiment. This embodiment will further explain the charging / heating control method for an electric vehicle power battery described in Embodiment 1. The first-order Thevenin equivalent circuit model inside the lithium-ion battery includes the ohmic internal resistance R 0 , Polarization resistance R 1 , Polarized capacitance C 1 and open circuit equivalent voltage source U OC ;

[0029] Ohm internal resistance R 0 One end of the connection is connected to the positive pole of the charging power supply, and the ohmic internal resistance R 0 The other end of the polarized capacitor C is connected at the same time 1 one end and the polarization resistance R 1 One end of the polarized capacitance C 1 The other end of the polarizing resistor R 1 The other end of the open circuit equivalent voltage source U OC The positive pole of the open circuit equivalent voltage source U OC The ...

specific Embodiment approach 3

[0030] Specific embodiment three, this embodiment is to further explain a kind of electric vehicle power battery charging / heating control method described in specific embodiment two, the formula of the lithium-ion battery first-order Thevenin equivalent circuit model described in step four is: :

[0031]

[0032] Among them, R 0 is the ohmic internal resistance, R 1 is the polarization internal resistance, C 1 is the polarized capacitance, U OC is the open circuit voltage of the lithium-ion battery, U is the terminal voltage of the lithium-ion battery, and s is the complex frequency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com