Electrophotographic photoreceptor, electrophotographic photoreceptor cartridge, and image formation device

A technology of electrophotography and photoreceptor, which is applied in the fields of optics, electrical recording, instruments, etc., can solve the problems of poor electrical characteristics and adhesion, and achieve the effect of excellent adhesion and sufficient wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0189]

[0190] Use a ball mill to disperse surface-treated titanium oxide in a mixed solvent with a mass ratio of methanol / 1-propanol of 7 / 3, thereby obtaining a dispersion slurry of surface-treated titanium oxide, which has an average primary particle size of Rutile-type titanium oxide with a diameter of 40 nm ("TTO55N" manufactured by Ishihara Sangyo Co., Ltd.) and 3% by mass of methyldimethoxysilane ("TSL8117" manufactured by Toshiba Silicone Co., Ltd.) relative to the titanium oxide were mixed by Henschel. machine for mixing. In the dispersion slurry, the mixed solvent of methanol / 1-propanol / toluene, and the compound represented by ε-caprolactam [the compound represented by the following formula (A)] / bis(4-amino-3-methylcyclohexyl) Methane [the compound represented by the following formula (B)] / hexamethylenediamine [the compound represented by the following formula (C)] / decamethylene dicarboxylic acid [the compound represented by the following formula (D) Compound] / oc...

Embodiment 2

[0231] A photoreceptor was produced in the same manner as in Example 1, except that the production of the second charge transport layer-forming coating liquid and the production of the first charge transport layer-forming coating liquid were changed as follows in Example 1. And carried out the evaluation, the results are shown in Table-2.

[0232]

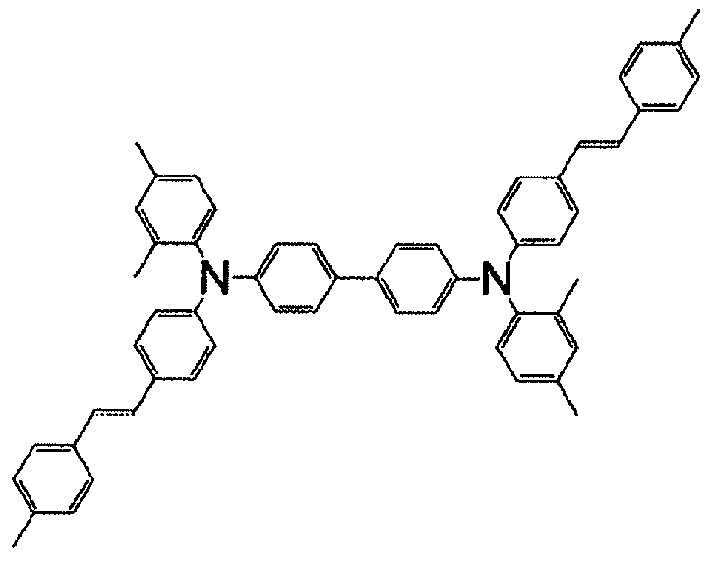

[0233] Make 100 parts of polycarbonate resin (PC2) (viscosity-average molecular weight 30,000) with the following repeating structural unit, 60 parts of compounds shown in the above-mentioned CT-5 as charge transport material, antioxidant (Ciba Specialty Chemicals company as additive) manufactured, trade name Irganox 1076) and 0.05 parts of silicone oil (manufactured by Shin-Etsu Silicone: trade name KF96) dissolved in 560 parts of a mixed solvent of tetrahydrofuran / toluene (8 / 2 (mass ratio)) to prepare the second charge Coating liquid for transmission layer formation.

[0234] [chemical formula 9]

[0235]

[0236]

[0237]...

Embodiment 3

[0239] A photoreceptor was produced in the same manner as in Example 1, except that the production of the second charge transport layer-forming coating liquid and the production of the first charge transport layer-forming coating liquid were changed as follows in Example 1. And carried out the evaluation, the results are shown in Table-2.

[0240]

[0241] Make 100 parts of polycarbonate resin (PC3) (viscosity-average molecular weight 50,000) with the following repeating structural unit, 60 parts of compounds shown in the above-mentioned CT-5 as charge transport material, antioxidant (Ciba Specialty Chemicals company as additive) 4 parts, product name Irganox 1076) and 0.05 parts of silicone oil (manufactured by Shin-Etsu Silicone Co., Ltd.: product name KF96) were dissolved in 610 parts of a mixed solvent of tetrahydrofuran / toluene (8 / 2 (mass ratio)), and the second charge was prepared. Coating liquid for transmission layer formation.

[0242] [chemical formula 10]

[024...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com