Preparation method of high performance seawater desalination reverse osmosis membrane

A reverse osmosis membrane and seawater desalination technology, applied in chemical instruments and methods, seawater treatment, semi-permeable membrane separation, etc., can solve the problems of membrane instability and achieve the effect of compact structure, uniform pore distribution and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

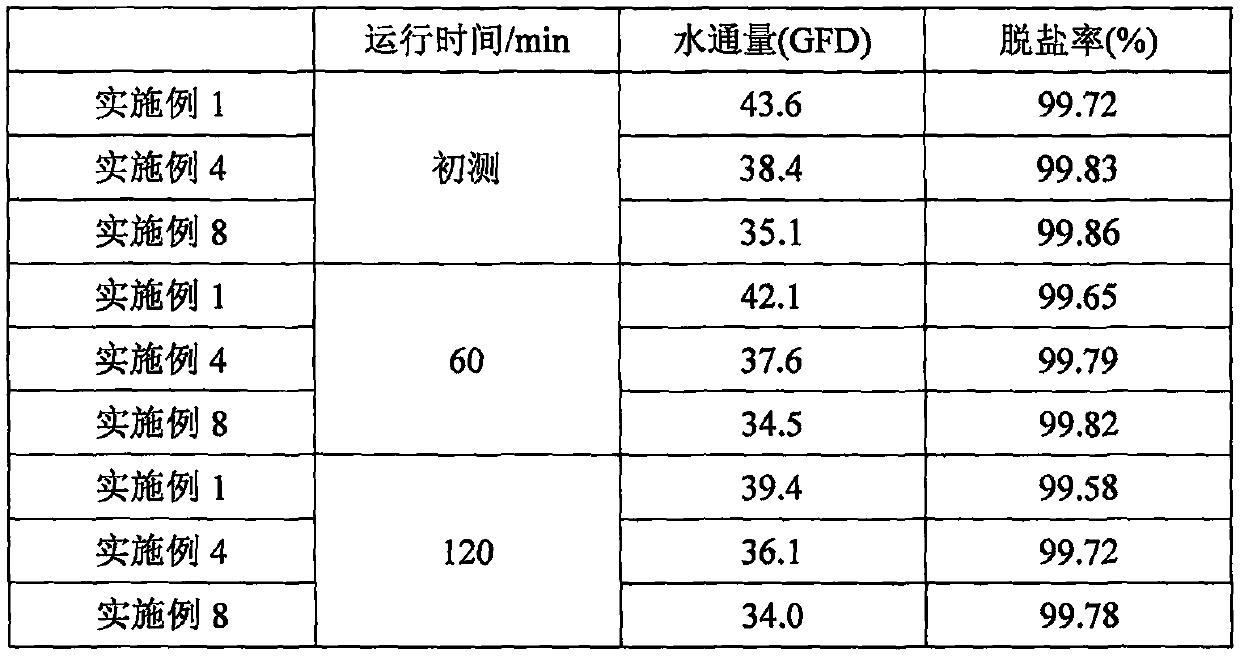

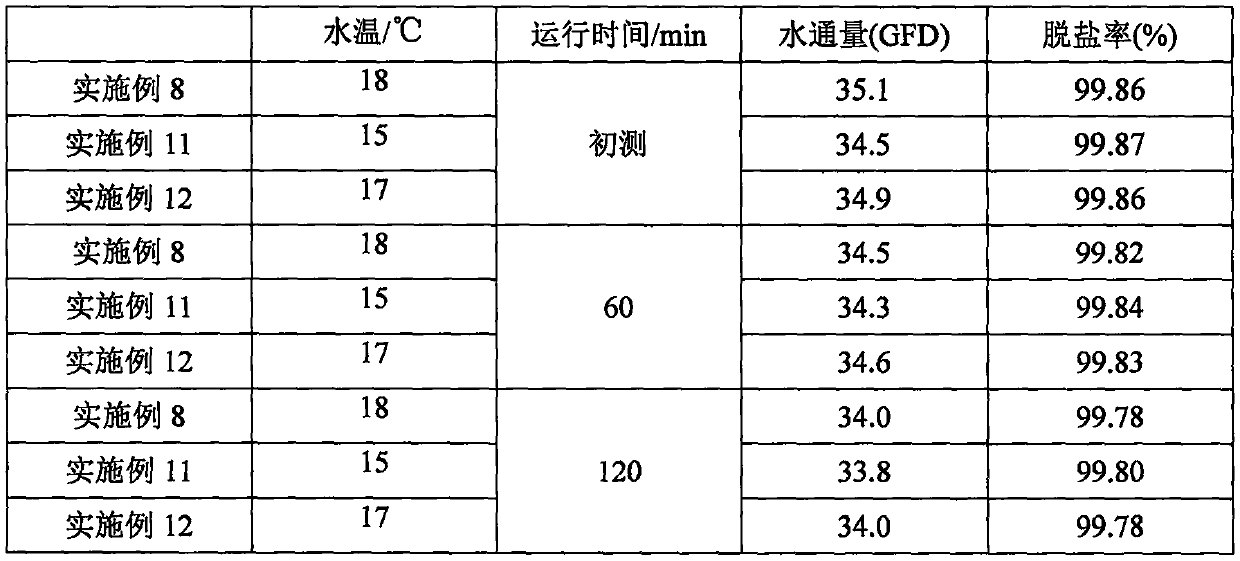

Examples

Embodiment 1

[0015] The preparation method of seawater desalination permeable membrane in the present embodiment is as follows:

[0016] 1) Preparation of polysulfone support layer: Weigh 16% polysulfone resin and dissolve it in N,N-dimethylformamide, stir at 70°C for 4 hours, and prepare a uniformly dispersed solution; the solution is filtered , After vacuum degassing, it is evenly coated on the non-woven fabric on a high-speed slit spraying machine, the wet film thickness is about 150 μm, and then immediately immersed in 18 ℃ pure water to gel and solidify into a film to obtain a polysulfone support layer;

[0017] 2) Configure an amine-containing aqueous phase solution: dissolve m-phenylenediamine in water, and its weight concentration in the aqueous solution is 3.5%. After it is completely dissolved, add surface activity that accounts for 1.5% by weight of the aqueous solution to the aqueous solution. After stirring evenly, add sodium hydroxide to adjust the pH value of the solution be...

Embodiment 2

[0021] The preparation method of seawater desalination permeable membrane in the present embodiment is as follows:

[0022] 1) Preparation of polysulfone support layer: Weigh 18% polysulfone resin and dissolve it in N,N-dimethylformamide, stir at 70°C for 4 hours, and prepare a uniformly dispersed solution; the solution is filtered , After vacuum degassing, it is evenly coated on the non-woven fabric on a high-speed slit spraying machine, the wet film thickness is about 150 μm, and then immediately immersed in 18 ℃ pure water to gel and solidify into a film to obtain a polysulfone support layer;

[0023] 2) Configure an amine-containing aqueous phase solution: dissolve m-phenylenediamine in water, and its weight concentration in the aqueous solution is 3.5%. After it is completely dissolved, add surface activity that accounts for 1.5% by weight of the aqueous solution to the aqueous solution. After stirring evenly, add sodium hydroxide to adjust the pH value of the solution be...

Embodiment 3

[0027] 1) Preparation of polysulfone support layer: Weigh 16% by weight of polysulfone resin and dissolve it in N,N-dimethylformamide, add 1.5% by weight of PVP-K30, and stir at 70°C for 4 hours , prepared into a uniformly dispersed solution; the solution was filtered and vacuum degassed, and then evenly coated on the non-woven fabric on a high-speed slit spraying machine, the wet film thickness was about 150μm, and then immediately immersed in 18°C pure water to gel curing into a film to obtain a polysulfone support layer;

[0028] 2) Configure an amine-containing aqueous phase solution: dissolve m-phenylenediamine in water, and its weight concentration in the aqueous solution is 3.5%. After it is completely dissolved, add surface activity that accounts for 1.5% by weight of the aqueous solution to the aqueous solution. After stirring evenly, add sodium hydroxide to adjust the pH value of the solution between 9 and 10 to obtain an amine-containing solution;

[0029] 3) con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap