Method for preparing solid-phase-method barium titanate through gluing

A technology of barium titanate and barium carbonate, which is applied in the field of preparing barium titanate by adding glue, can solve the problems of serious agglomeration of barium titanate and uneven Ba/Ti ratio, so as to ensure dispersion and uniformity, Uniform particles to avoid uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

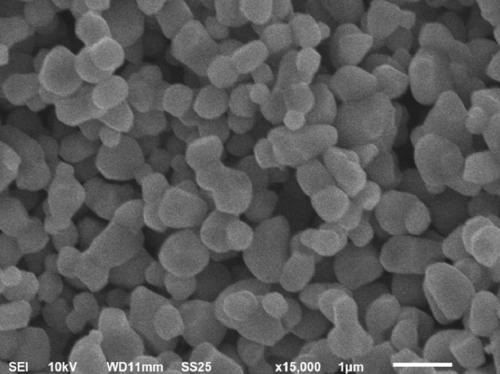

Image

Examples

Embodiment 1-9

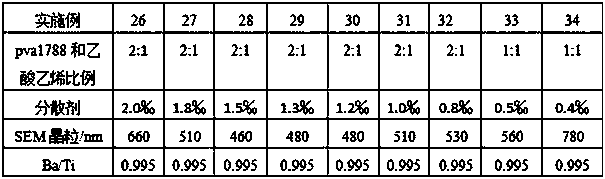

[0024] Add 250g of polyvinyl alcohol pva1788 and vinyl acetate mixture (the ratio of polyvinyl alcohol pva1788 to vinyl acetate is 2:1) into 5kg of water, dissolve at 60-70°C, and filter through a sieve to make glue. Then weigh 5.56 g of glue and 0.28 g of polyacrylamide and polyethylene glycol mixed dispersant, add it to 272.18 g of pure water (the ratio of polyacrylamide and polyethylene glycol is 3:1), and stir to dissolve. Then add 80.05g of titanium dioxide and 197.34g of barium carbonate (Ba / Ti=1, the ignition loss of titanium dioxide and barium carbonate are 0.28% and 0.32% respectively), after stirring, circulate and grind for 60 minutes through a sand mill, and then use a 120°C oven Drying, when the moisture content is less than 0.5%, manually pass through a 40-mesh sieve for calcination, at a temperature of 1000-1100°C, and keep warm for 2-3 hours. The test results are shown in Table 1:

[0025]

[0026] It can be seen from Table 1 that as the calcination tempera...

Embodiment 10-16

[0028] Under the method of Examples 1-9, the experiment of dispersant ratio was carried out. Ba / Ti=0.995, the solid-to-liquid ratio is 1, the total mass ratio of polyvinyl alcohol pva1788 and vinyl acetate to titanium dioxide and barium carbonate is 2‰, stir and sand for 60 minutes, dry in an oven at 120°C, and manually when the moisture content is less than 0.5% Pass through a 40-mesh sieve for calcination, for 2 hours, at a temperature of 1000°C, and keep warm for 2 hours. The test results are shown in Table 2:

[0029]

[0030] It can be seen from Table 2 that the ratio of dispersant has a significant impact on the particle size of the crystal grains, and the particle size is the smallest when the ratio of polyacrylamide to polyethylene glycol is 3:1.

Embodiment 17-25

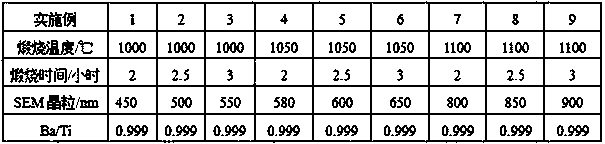

[0032] Under the method of Examples 1-9, the dispersant content was fixed at 1.5‰, Ba / Ti=0.995, the solid-liquid ratio was 1, and the ratios of pva1788 and vinyl acetate were different. Stir and sand mill for 60 minutes, dry in an oven at 120°C, manually pass through a 40-mesh screen for calcination when the moisture content is less than 0.5%, and heat at 1000°C for 2 hours. The test results are shown in Table 3:

[0033] It can be seen from Table 3 that when the content of dispersant is 1.5‰ of the total mass of titanium dioxide and barium carbonate, and the ratio of pva1788 and vinyl acetate is 2:1, the grain size of barium titanate is the smallest.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com