Process for recovering precious metal from sulphide ore based on thiosulfate leaching method

A technology of thiosulfate and precious metal thiosulfuric acid, which is applied in photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problems of slow recovery speed, small adsorption capacity, high cost, etc., and achieve simple and efficient adsorbent The effect of desorption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of sulfide ore recovery precious metal technology based on thiosulfate leaching method comprises the following steps:

[0048] Select a gold ore from a concentrator, grind it in a solution containing ammonium thiosulfate, ammonium sulfite, and ammonia water, send the ground pulp to the leaching equipment, add an appropriate amount of water to control the concentration of the pulp, and lower the temperature Controlled at 50°C, heated and stirred for leaching for 10h. After testing, the leaching rate of gold reaches 93%, and the gold content in the leaching solution is 1mg / L;

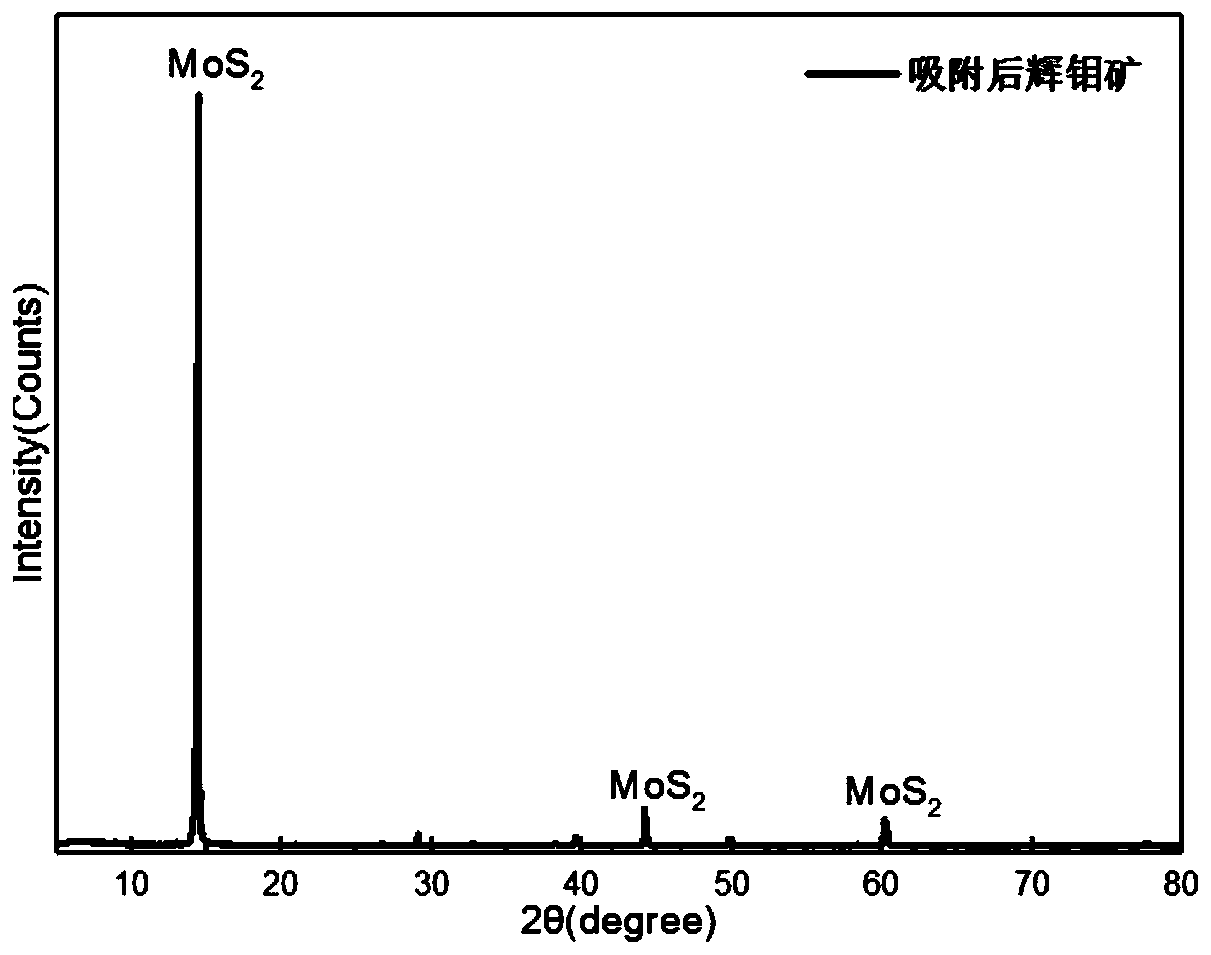

[0049]Obtain 1L of the obtained leaching solution, adjust the pH of the leaching solution to 12.00; put 0.03g of molybdenite in the leaching solution to absorb gold thiosulfate complex for 50 hours; put the gold-loaded molybdenite obtained by separation and removal of impurities into 14% NaOH solution , ultrasonicated for 60 min at room temperature to obtain gold-containing noble solution. ...

Embodiment 2

[0052] A kind of sulfide ore recovery precious metal technology based on thiosulfate leaching method comprises the following steps:

[0053] Select a gold ore from a concentrator, grind it in a solution containing ammonium thiosulfate, ammonium sulfite, and ammonia water, send the ground pulp to the leaching equipment, add an appropriate amount of water to control the concentration of the pulp, and lower the temperature Controlled at 50°C, heated and stirred for leaching for 10h. After testing, the leaching rate of gold reaches 93%, and the gold content in the leaching solution is 1mg / L;

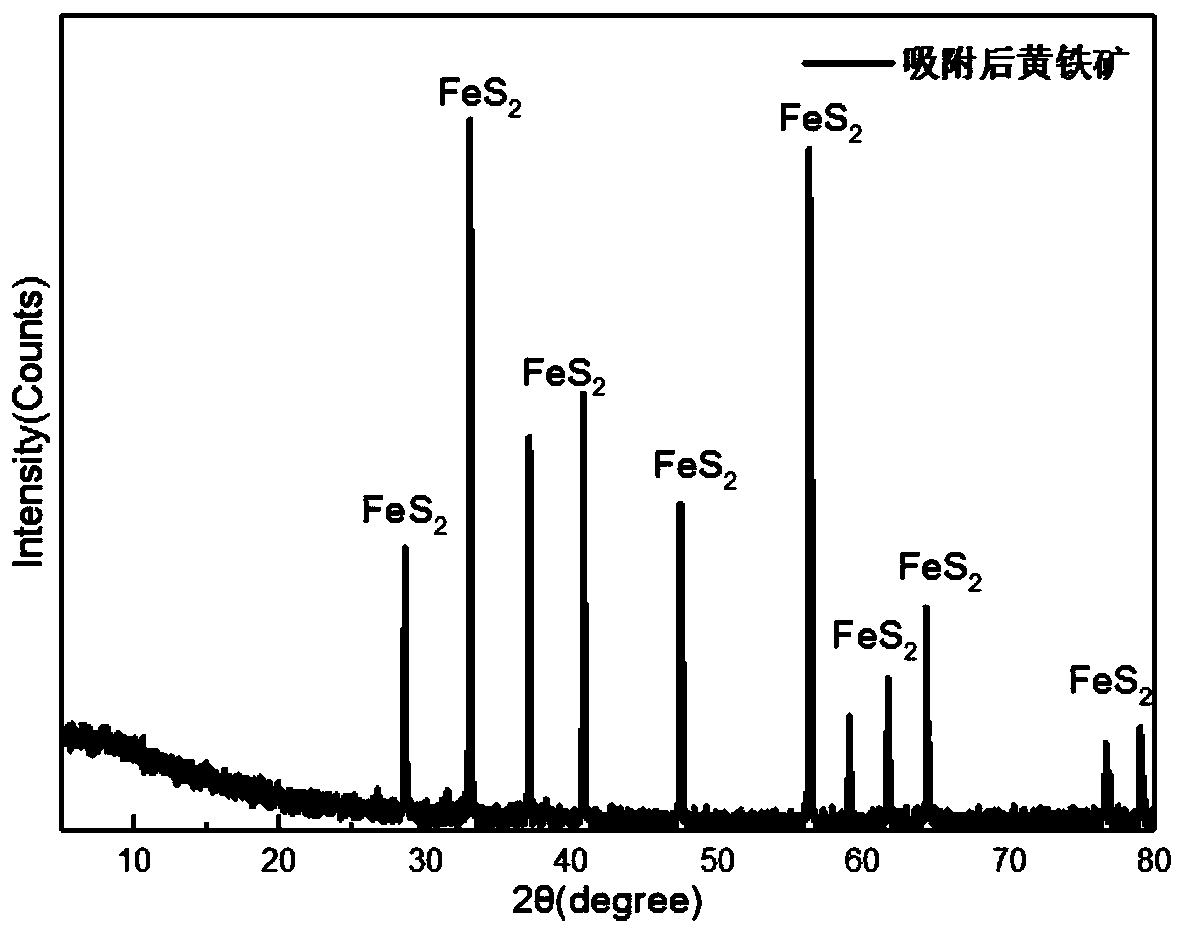

[0054] Obtain 10L of the obtained leaching solution, adjust the pH of the leaching solution to 12.00; put 0.3g of chalcopyrite in the leaching solution to absorb gold thiosulfuric acid complex for 50h; put the gold-loaded chalcopyrite obtained by separating and removing impurities into 4% NaOH solution , ultrasonicated for 60 min at room temperature to obtain gold-containing noble solution....

Embodiment 3

[0057] A kind of sulfide ore recovery precious metal technology based on thiosulfate leaching method comprises the following steps:

[0058] Select a gold ore from a concentrator, grind it in a solution containing ammonium thiosulfate, ammonium sulfite, and ammonia water, send the ground pulp to the leaching equipment, add an appropriate amount of water to control the concentration of the pulp, and lower the temperature Controlled at 50°C, heated and stirred for leaching for 10h. After testing, the leaching rate of gold reaches 93%, and the gold content in the leaching solution is 1mg / L;

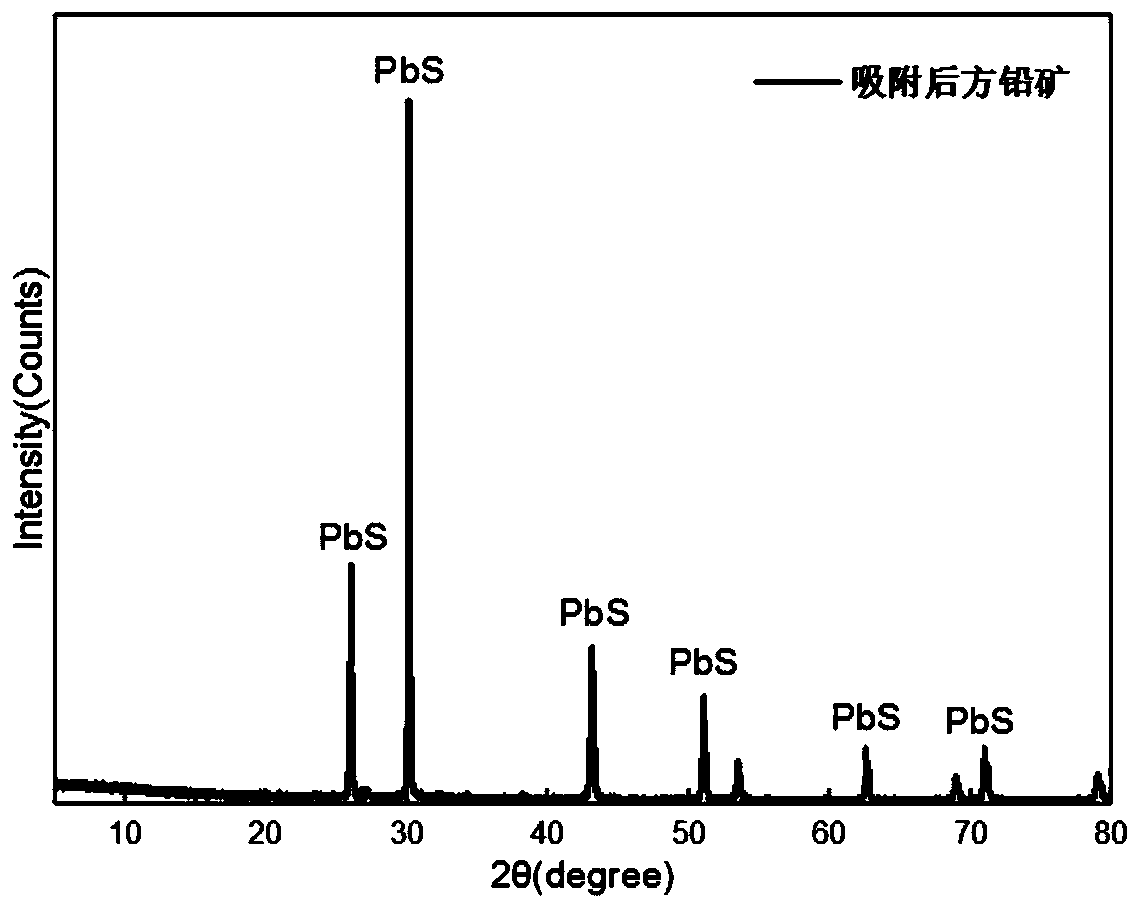

[0059] Obtain 1L of the obtained leaching solution, adjust the pH of the leaching solution to 10.00; put 0.03g of galena in the leaching solution to absorb the gold thiosulfuric acid complex for 50 hours; put the gold-loaded galena obtained by separation and removal of impurities into 14% NaOH In the solution, sonicate for 10 min at room temperature to obtain a precious solution containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com