Preparation method of high corrosion-resistant and wear-resistant coating on soluble magnesium alloy surface

A technology of wear-resistant coating and magnesium alloy, which is applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of tool failure, fast corrosion rate, erosion and wear, etc., and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

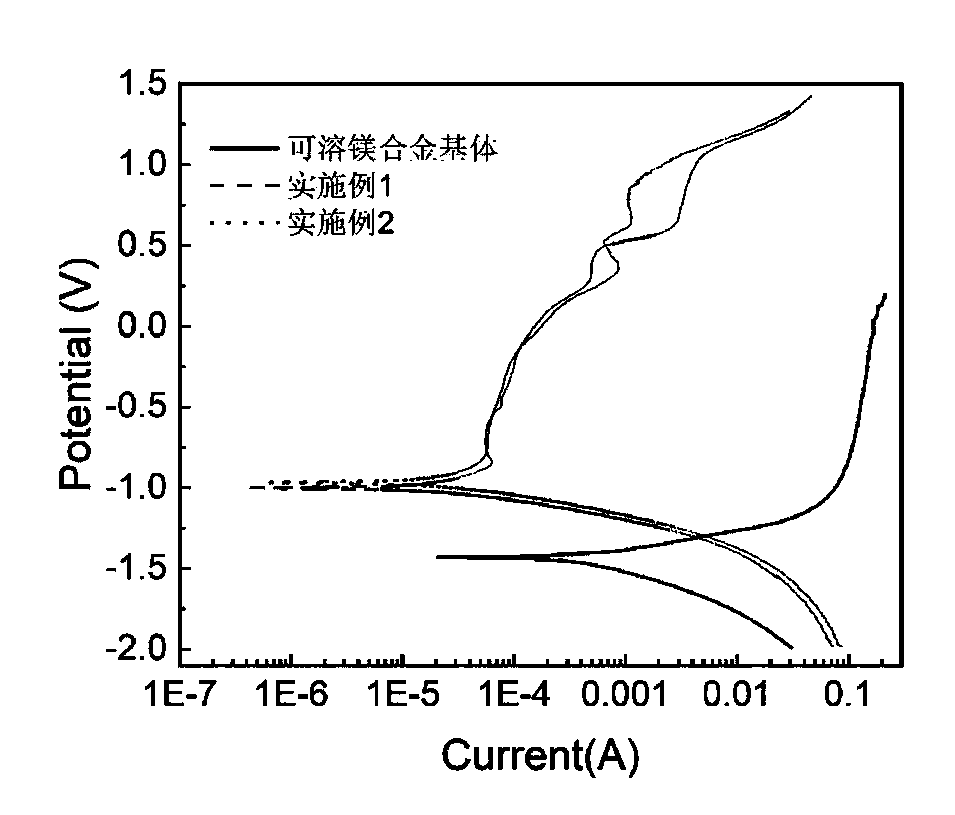

Embodiment 1

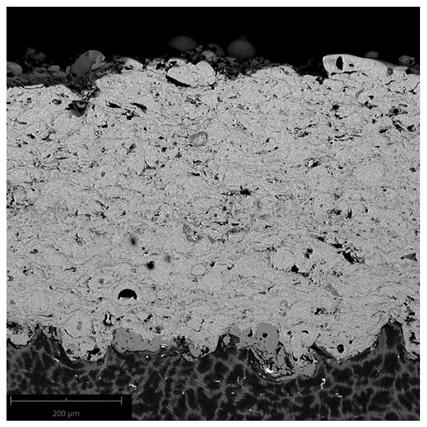

[0021] Embodiment 1 Spraying iron-based amorphous coating on the surface of soluble magnesium alloy

[0022] (1) Place the soluble magnesium alloy substrate in ethanol for ultrasonic cleaning;

[0023] (2) 1 hour before spraying, the soluble magnesium alloy substrate after ultrasonic cleaning was subjected to dry sandblasting treatment, the abrasive used in the sandblasting treatment was 20# white corundum sand, and the pressure of the sandblasting treatment was 0.65MPa, so The speed of the sandblasting treatment is 0.5cm / s, and the time of the sandblasting treatment is 5min;

[0024] (3) Use a steel brush to polish the surface of the soluble magnesium alloy substrate after dry sandblasting, remove particulate matter, and obtain a clean soluble magnesium alloy substrate;

[0025] (4) Drying 250-300 mesh iron-based amorphous alloy particles under vacuum conditions at 100° C. for 1 hour to obtain dry iron-based amorphous alloy particles;

[0026] (5) fixing the soluble magnesi...

Embodiment 2

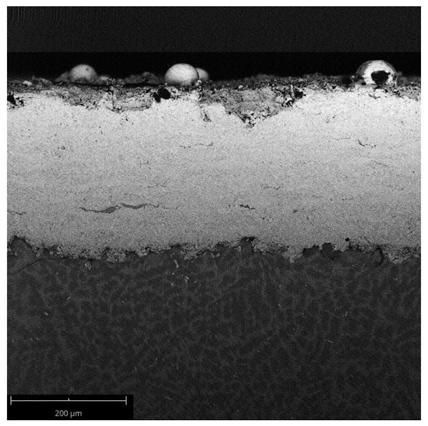

[0029] Embodiment 2 Soluble magnesium alloy surface spraying WC coating

[0030] (1) Place the soluble magnesium alloy substrate in ethanol for ultrasonic cleaning;

[0031] (2) 1 hour before spraying, the soluble magnesium alloy substrate after ultrasonic cleaning was subjected to dry sandblasting treatment, the abrasive used in the sandblasting treatment was 20# white corundum sand, and the pressure of the sandblasting treatment was 0.6MPa. The speed of the sandblasting treatment is 0.5cm / s, and the time of the sandblasting treatment is 5min;

[0032] (3) Use a steel brush to polish the surface of the soluble magnesium alloy substrate after dry sandblasting, remove particulate matter, and obtain a clean soluble magnesium alloy substrate;

[0033] (4) Dry WC particles of 250-300 mesh under vacuum conditions at 100°C for 1 hour to obtain dried WC particles;

[0034] (5) fixing the soluble magnesium alloy substrate obtained in step (3); using the dried WC particles obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com