Soil and water loss control method based on microbial mineralization

A technology of mineralization and microorganisms, applied in the direction of chemical instruments and methods, applications, soil protection, etc., can solve the problems of low curing reaction efficiency, unrepresentative, MICP technology is not suitable for strengthening cohesive soil, etc., to achieve improvement Infiltration efficiency and infiltration depth, good air permeability and water permeability, good infiltration and diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The soil in this example is a horizontal soil with a permeability coefficient of 5×10 -4 m / s.

[0053] The microbial bacterial liquid adopts Bacillus sarcina pasteuri, and the medium is: yeast extract 20g / L, ammonium sulfate 10g / L, 0.13mol Tris-Buffer 15.75g / L; the bacterial liquid is activated when taking it, and the temperature during the activation process is controlled at 25°C, the shaker speed is 120rmp / min, and the pH is controlled at 8.1; the activated bacterial liquid is stored in a refrigerator at 4°C; the enzyme activity level of the microbial liquid is controlled by the conductivity method to be 1.8mS / (cm min -1 ), using a spectrophotometer to control the absorbance value OD of the bacterial solution concentration at a wavelength of 600nm 600 is 1.0Abs.

[0054] Concentration of cementing liquid is 0.1M, and each liter contains: 6.0g of urea, 11g of calcium chloride, and 3g of nutrient broth.

[0055] A method for preventing and controlling water and soil ...

Embodiment 2

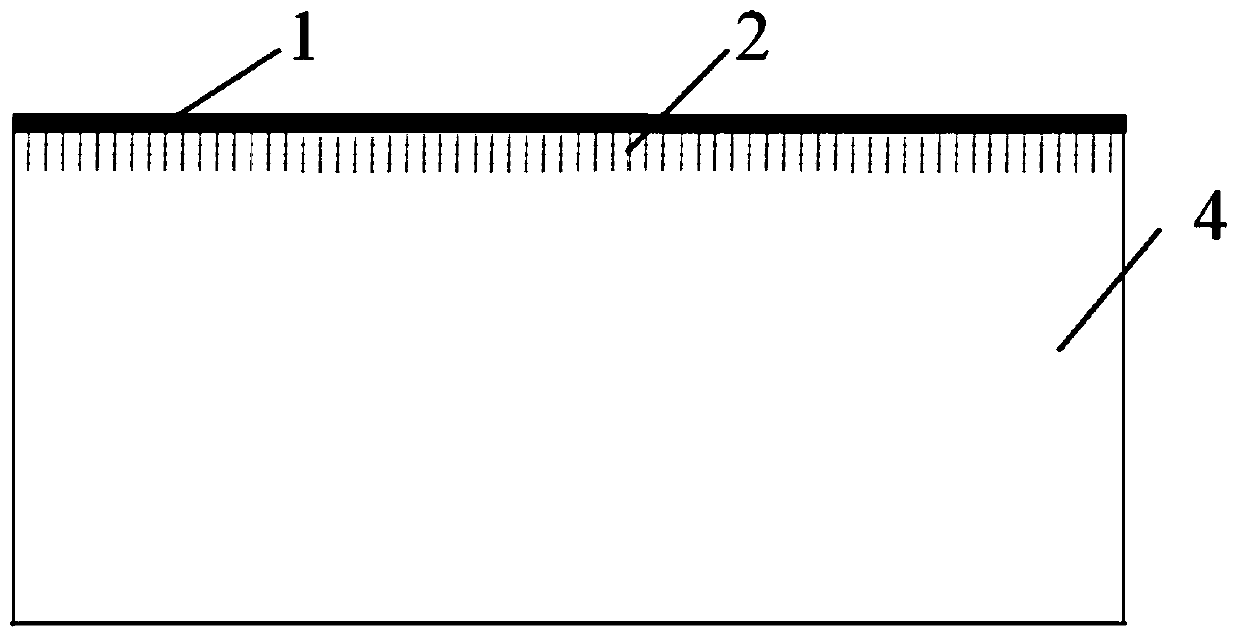

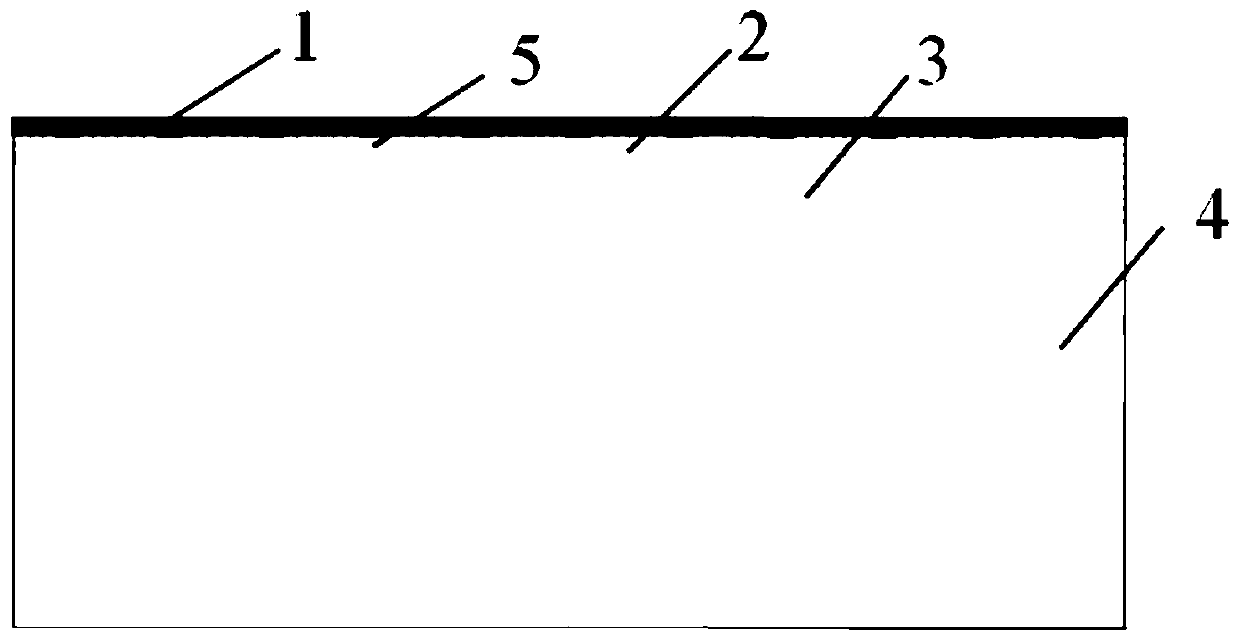

[0061] The processing steps of this embodiment are basically the same as in Embodiment 1, the difference is that the permeability coefficient is selected to be 5×10 -5 The horizontal soil mass of m / s is tested, and the experimental results show that: figure 1 As shown, microorganisms form a layer of 2.5cm cemented and solidified layer on the soil surface. Compared with the untreated soil, the solidified layer increases the penetration resistance of the soil surface by 15%, and the soil erosion rate decreases by 10%, illustrating this embodiment. method for permeability coefficients less than 10 -4 The soil mass of m / s also has a certain curing effect, but the effect is not as good as the permeability coefficient greater than 10. -4 m / s of soil.

Embodiment 3

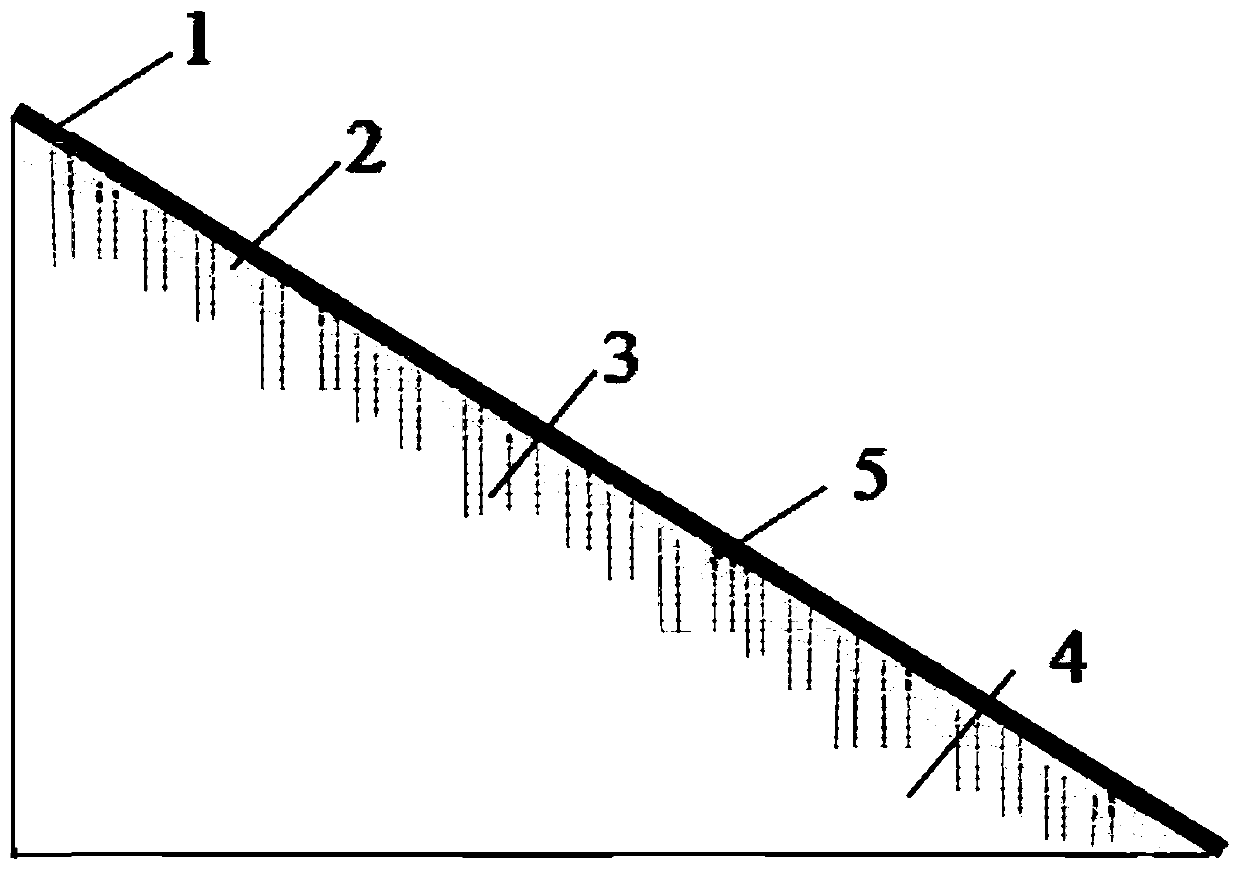

[0063] The soil in this embodiment is a 35° slope, and the soil permeability coefficient is 5×10 -4 m / s.

[0064] The microbial bacterial liquid adopts Bacillus sarcina pasteuri, and the medium is: yeast extract 20g / L, ammonium sulfate 10g / L, 0.13mol Tris-Buffer 15.75g / L; the bacterial liquid is activated when taking it, and the temperature during the activation process is controlled at 25°C, shaker speed is 120rmp / min; the activated bacterial liquid is stored in a refrigerator at 4°C; the enzyme activity level of the microbial liquid is controlled by the conductivity method to be 1.9mS / (cm min -1 ), using a spectrophotometer to control the absorbance value OD of the bacterial solution concentration at a wavelength of 600nm 600 It is 1.4Abs.

[0065] Concentration of cementing liquid is 0.5M, and each liter contains: 30g of urea, 55g of calcium chloride, and 3g of nutrient broth.

[0066] A method for preventing and controlling water and soil loss based on microbial mineral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com