Ultra-long gravity heat pipe geothermal mining device with steam-water separation function

A steam-water separation device, gravity heat pipe technology, applied in geothermal energy, separation method, geothermal energy power generation and other directions, can solve the problems of increasing system power consumption, unable to make unpowered auxiliary heat pipe, reducing system efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

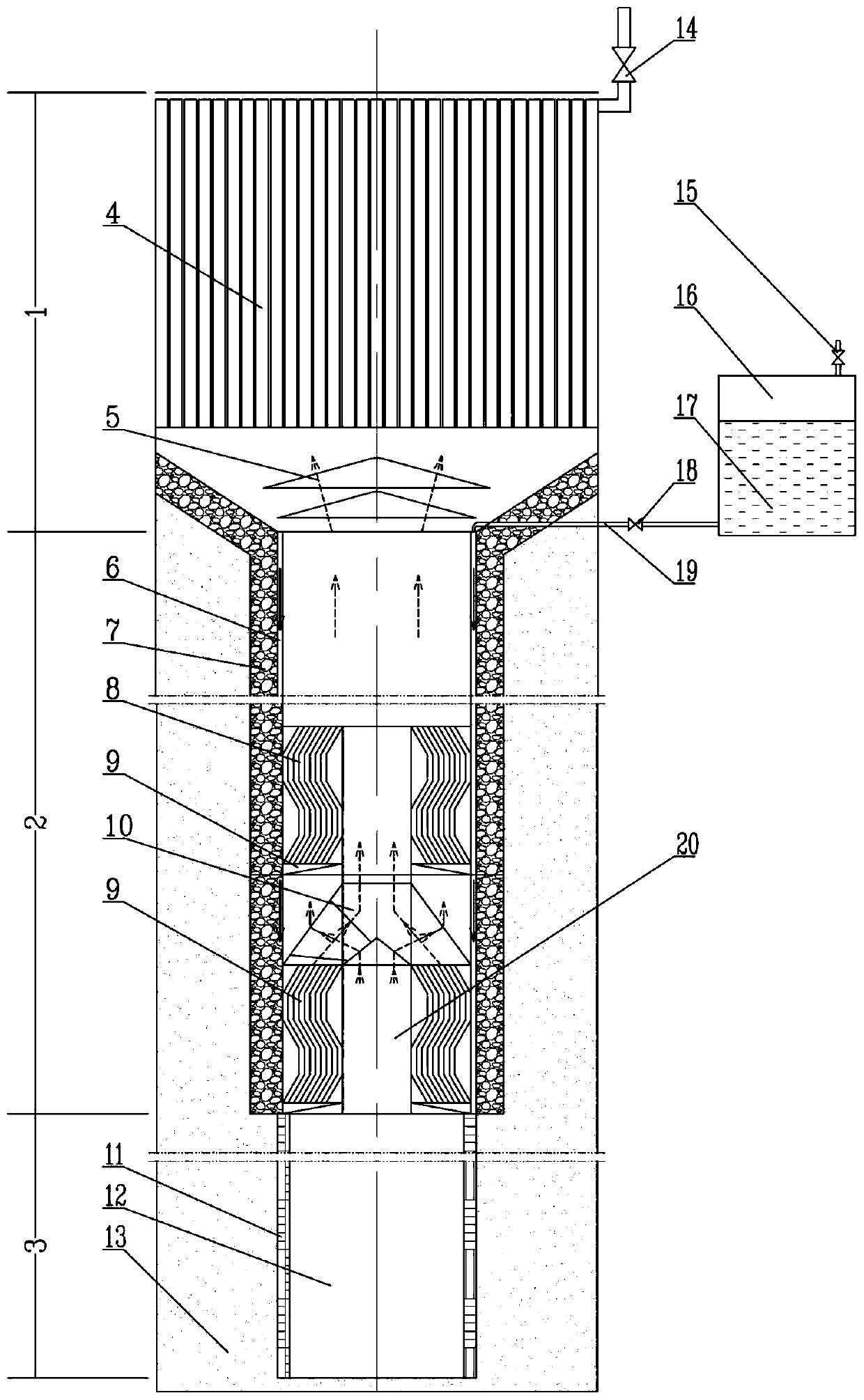

Embodiment 1

[0034] figure 1 It is a schematic diagram of the device of Example 1 of the present invention. The heat extraction section 3 of the ultra-long gravity heat pipe with steam-water separation is directly to the bottom of the geothermal well 13, and the geothermal energy of the geothermal well 13 is transferred to the heat extraction section 3. Some thermally conductive fillers can be filled between the heat extraction section 3 and the geothermal well 13 to increase the heat transfer effect. The working fluid contained in the porous core layer 11 on the wall of the heating section 3 is heated and evaporated to generate working fluid vapor. The liquid vapor rises to reach the adiabatic section 2. A steam-water separation device is provided at the junction of the adiabatic section 2 and the heat-taking section 3. An air duct 20 and a baffle 9 are arranged in the middle of the inlet of the steam-water separation structure. The steam is divided into two paths, one way enters the up...

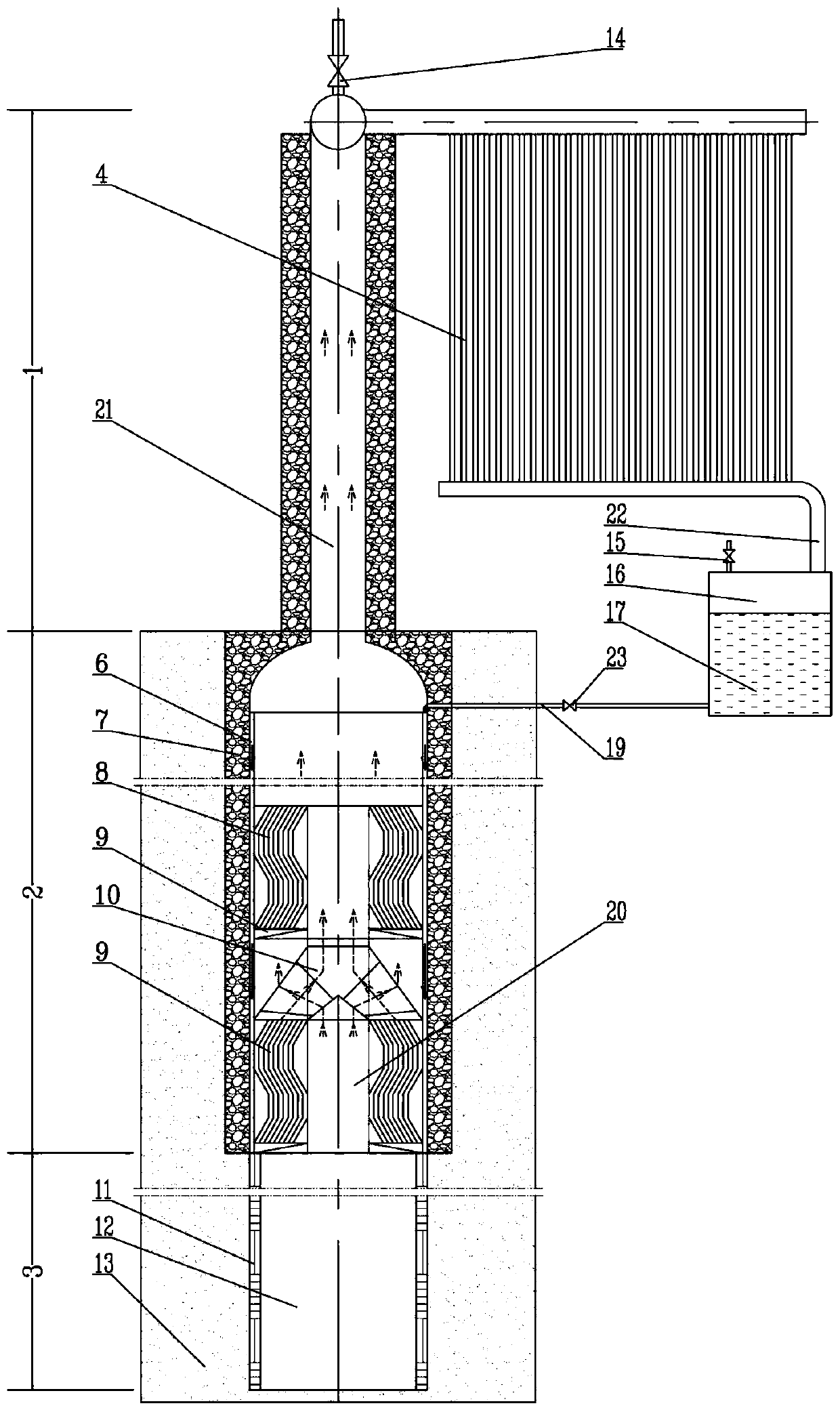

Embodiment 2

[0037] figure 2 It is a schematic diagram of the device of Embodiment 2 of the present invention. The heat extraction section 3 of the ultra-long gravity heat pipe with steam-water separation is directly to the bottom of the geothermal well 13, and the geothermal energy of the geothermal well 13 is transferred to the heat extraction section 3. Some thermally conductive fillers can be filled between the heat extraction section 3 and the geothermal well 13 to increase the heat transfer effect. The working fluid contained in the porous core layer 11 on the wall of the heating section 3 is heated and evaporated to generate working fluid vapor. The vapor with liquid rises to reach the adiabatic section 2, and the connection between the adiabatic section 2 and the heat extraction section 3 is provided with a steam-water separation device. An air duct 20 and a baffle 9 are arranged in the middle of the inlet of the steam-water separation structure. The steam is divided into two pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com