Spacecraft sealed cabin gas sampling and analyzing system for vacuum thermal test and analyzing method

A vacuum thermal test and gas sampling technology, which is applied in thermal excitation analysis, material excitation analysis, etc., can solve the problems of low gas composition accuracy, complex sampling system structure, and many processes, and achieve simple structure, simple operation process, and high precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

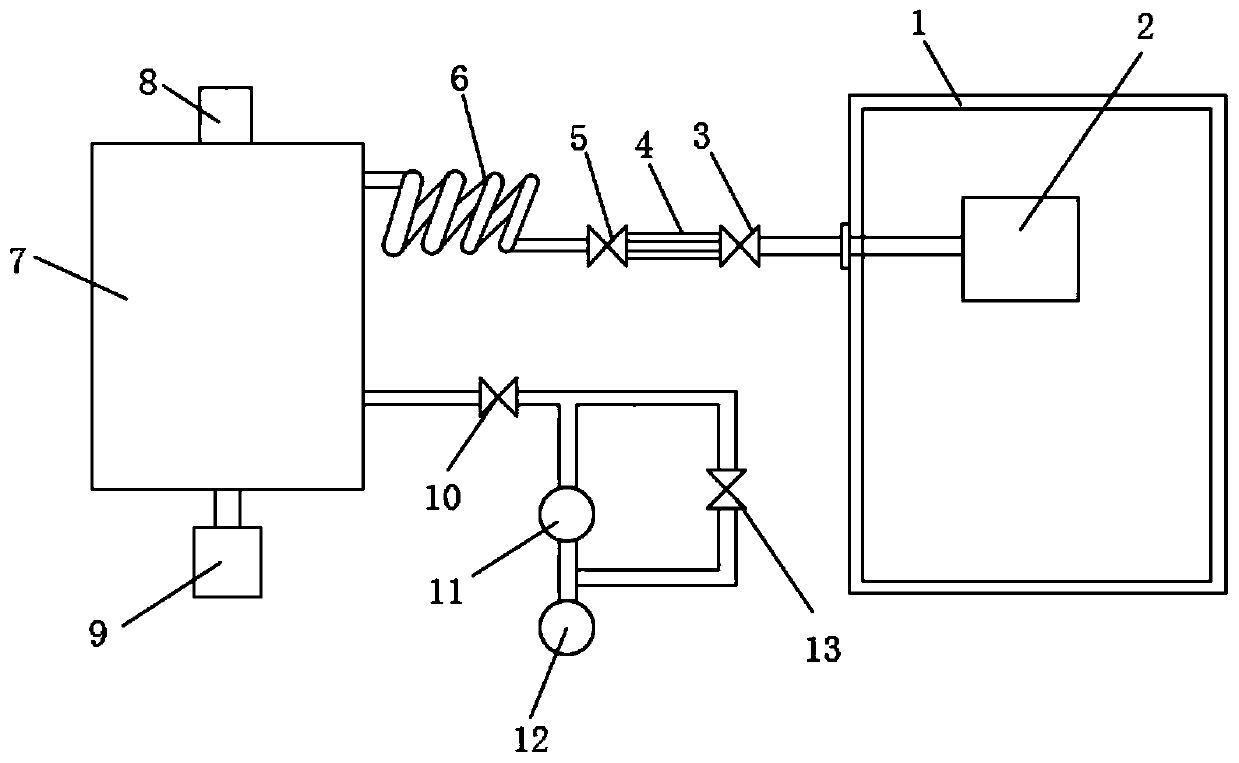

[0030] Embodiment one, refer to figure 1 As shown, the spacecraft airtight cabin gas sampling and analysis system for vacuum thermal test includes space environment simulator 1, sampling analysis system and gas sampling pipeline. Space environment simulator 1 is provided with airtight cabin 2, and the sampling analysis system includes sampling chamber 7. Gas analysis device, air pressure detection device, pump group and valve group, the sealed cabin 2 is connected to the sampling chamber 7 through the gas sampling pipeline, the gas analysis device and the air pressure detection device are fixedly installed on the sampling chamber 7, and the pump group passes through The valve group is communicated with the sampling chamber 7 .

Embodiment 2

[0031] Embodiment 2. The gas sampling pipeline includes a spiral gradually expanding air inlet pipe 6, a temperature control pipe 4, a first solenoid valve 3 and a butterfly valve 5. One end of the spiral gradually expanding air inlet pipe 6 is connected to the sampling chamber 7, and the spiral gradually expanding air inlet pipe 6 The other end is communicated with one end of the temperature control tube 4 through the butterfly valve 5 , and the other end of the temperature control tube 4 is communicated with the sealed cabin 2 through the first electromagnetic valve 3 .

Embodiment 3

[0032] Embodiment 3. The pump set includes a molecular pump 11 and a scroll pump 12. The molecular pump 11 is a high-vacuum molecular pump with a model of TwisTorr 704F, which has a higher compression ratio and front-stage pressure resistance. A higher compression ratio (especially for small molecular gases) can bring better ultimate vacuum, and a higher backing pressure allows the use of smaller backing pumps, thereby reducing the overall vacuum system. Cost and size, the scroll pump 12 is an Agilent Varian scroll dry pump SH-100, the valve group includes a second solenoid valve 10 and a third solenoid valve 13, one end of the second solenoid valve 10 communicates with the sampling chamber 7, the second The other end of the solenoid valve 10 is connected to the molecular pump 11 and one end of the third solenoid valve 13 respectively, and one end of the scroll pump 12 is connected to the other end of the molecular pump 11 and the third solenoid valve 13 respectively. Since the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com