A landscape garden ecological maintenance device

A garden and ecological technology, applied in the field of garden maintenance equipment, can solve the problems of increasing labor intensity of workers, improper storage of bleaching powder, and large labor workload of workers, reducing labor workload, improving convenience and practicability, and strong structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

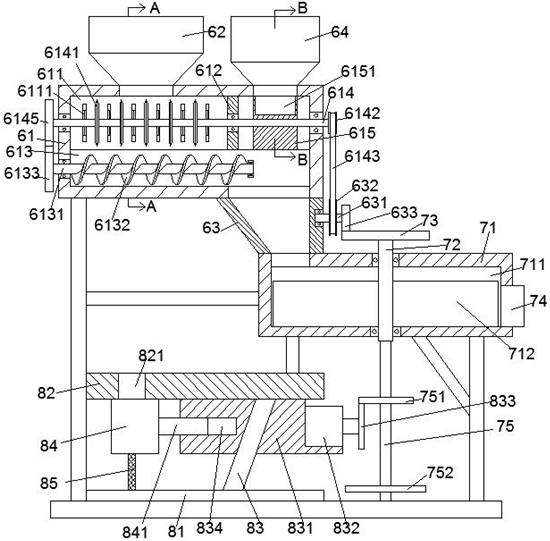

[0025] When it is necessary to control and adjust the throwing speed, the positive and negative rotation of the adjusting screw 85 is controlled by the second motor 821, and then the adjusting screw 85 drives the moving block 84 and the push slide bar 841 to move up and down. The chute 834 is in a state of sliding fit connection, and then the push slide bar 841 drives the adjustment slide block 831 to slide up and down along the inclined direction of the inclined guide slide bar 83. When the moving block 84 drives the adjustment slide block 831 to abut against the upper plate body 82, At this time, the power drive plate 833 on the right side of the first motor 832 is driven by the adjustment slider 831 and the first power connection plate 751 is in a power cooperation connection state, and the first power connection plate 751 and the throwing rotating blade are driven by the first motor 832 712 rotates, and then realizes high-speed throwing work; The power connection plate 752...

Embodiment 2

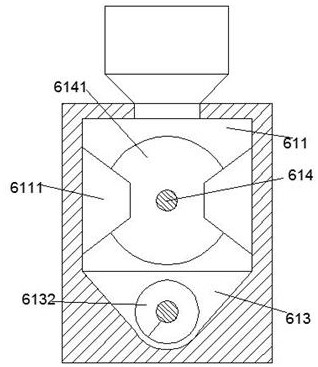

[0027] When crushing work is required, the agglomerated raw materials are poured into the first feed hopper 62, and fall into the first cavity 611 on the left side of the separation plate 612 through the first feed hopper 62. The three power connecting discs 73 and the fourth power connecting disc 633 are connected in power, and then the fourth power connecting disc 633 drives the second pulley 632 to rotate, and the transmission belt 6143 on the second pulley 632 drives the first pulley 6142 and the third pulley 6143. The rotating shaft 614 rotates, and then the third rotating shaft 614 drives the crushing knife 6141 to crush the agglomerated raw materials. When the power drive plate 833 and the first power connecting plate 751 are in a power cooperative connection state, the high-speed crushing work of the crushing knife 6141 is realized. At this time, the first gear 6145 drives the second gear 6133 and the fourth rotating shaft 6131 to rotate, and then the fourth rotating sh...

Embodiment 3

[0029] When crushing work is required, the agglomerated raw materials are poured into the second feed hopper 64. Since the third rotating shaft 614 drives the feeding turntable 615 to rotate, when the storage groove 6151 is in contact with the second feed hopper 64 At this time, the raw material in the second feeding hopper 64 falls into the material storage groove 6151, and the raw material in the material storage groove 6151 is poured into the material guide channel 63 through the rotation of the feeding turntable 615, and falls through the material guide channel 63. into the throwing housing 71, and the raw materials are thrown out through the throwing port 74 by the rotation of the throwing rotary blade 712.

[0030] The beneficial effects of the present invention are: the present invention is simple in structure, easy to operate, reduces the labor load of workers, prevents the human body from being easily poisoned due to long-term contact with bleaching powder, and improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com