A kind of colored asphalt and preparation method thereof

A colored asphalt and light-colored technology, which is applied in the field of colored asphalt and its preparation, can solve problems such as instability, easy peeling of colored asphalt, poor weather resistance and adhesion performance, and achieve various colors, low cost of raw materials, and good quality. The effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Mix 35 parts of paraffin oil, 5 parts of inorganic pigments, nano-montmorillonite 8, and wollastonite 12 in a high-speed mixer for 20 minutes at a speed of 400 rpm to obtain material 1;

[0036] (2) Mix 15 parts of sarin resin, 5 parts of POE, 10 parts of light-colored rosin, and 10 parts of cross-linked polyethylene in a high-speed mixer. The speed of the high-speed mixer is 400 rpm, and the time is 5 minutes to obtain material 2;

[0037] (3) Add the material 2 in step 2 from the main feeding port and the material 1 in step 1 from the side feeding port into the parallel twin-screw extruder to granulate. Granules, and the resulting pellets were dried at 60°C for 2 hours to obtain the colored asphalt raw material.

Embodiment 2

[0039] (1) 45 parts of paraffin oil, 5 parts of inorganic pigments, 15 parts of nano-montmorillonite, and 5 parts of wollastonite were mixed in a high-speed mixer for 20 minutes at a speed of 400 rpm to obtain material 1;

[0040] (2) Mix 10 parts of sarin resin, 5 parts of POE, 8 parts of light-colored rosin, and 7 parts of cross-linked polyethylene in a high-speed mixer. The speed of the high-speed mixer is 400 rpm, and the time is 5 minutes to obtain material 2;

[0041] (3) Add the material 2 in step 2 from the main feeding port and the material 1 in step 1 from the side feeding port into the parallel twin-screw extruder to granulate. Granules, and the resulting pellets were dried at 60°C for 2 hours to obtain the colored asphalt raw material.

Embodiment 3

[0047] The preparation method of colored asphalt mixture is as follows:

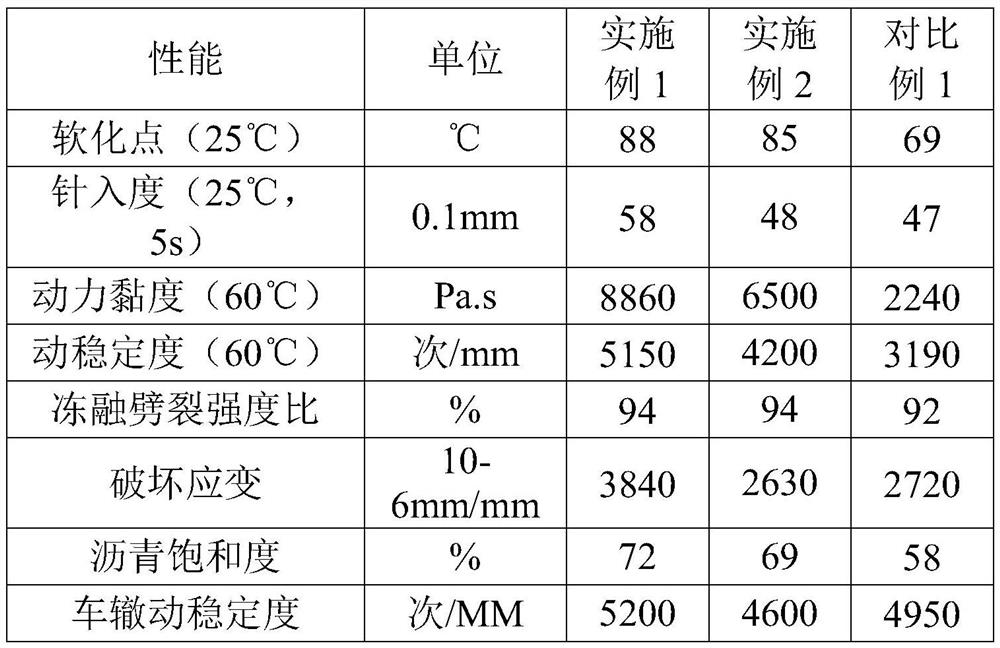

[0048] The color asphalt raw material prepared in the above-mentioned 2 embodiments and comparative example 1 of 25% mass fraction and a small amount of crosslinking agent, dispersant and other auxiliary agents are added to the asphalt aggregate (coarse aggregate , fine aggregate, ore powder), shear and grind for 30 minutes through the mill of the mixer truck, and stir and develop into a colored asphalt mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com