Toilet lid containing rice hull and wood powder and manufacturing process thereof

A manufacturing process and technology for a toilet cover, which is applied to the toilet cover containing rice husk and wood powder and its manufacturing process field, can solve the problems of reducing the processing performance, mechanical properties and durability of composite materials, difficult to degrade the toilet cover, and polluting the environment. , to achieve the effect of convenient control, improved reuse rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A toilet cover containing rice husk and wood flour, the toilet cover is made of a mixture by hot pressing, and the mixture includes the following raw materials in parts by weight:

[0061] 30 parts rice husk

[0062] 30 parts wood flour

[0063] Urea-formaldehyde glue 10 parts.

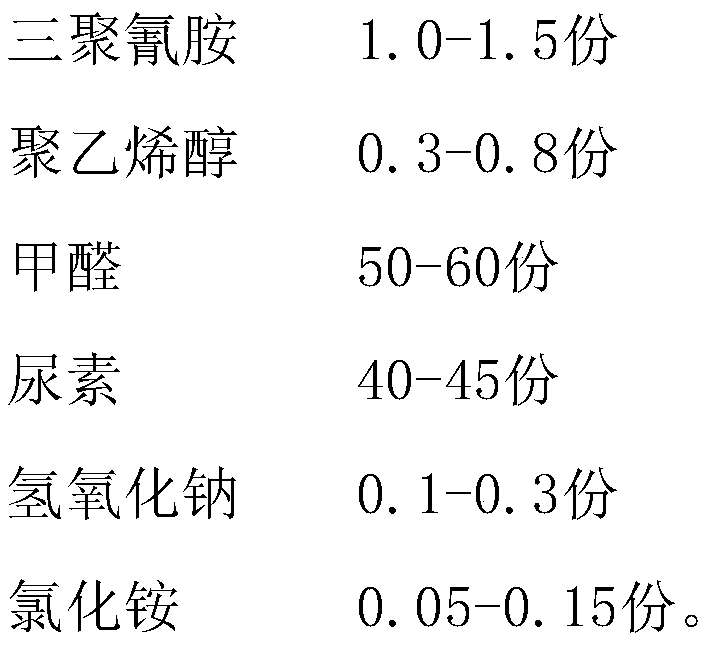

[0064] Described urea formaldehyde glue comprises the raw material of following weight portion:

[0065]

[0066] Described urea formaldehyde glue is made by following steps:

[0067] Step A: According to parts by weight, add formaldehyde into the reaction vessel, heat up to 35°C, add 25% sodium hydroxide by volume to adjust the pH value to 8.2, then add melamine and 25% of the total urea consumption while stirring urea, the temperature was raised to 82°C within 40 minutes during the stirring process, and after the addition was completed, the heat preservation reaction was carried out for 30 minutes, and then the temperature was lowered to 50°C to obtain material A;

[0068] Step B: addi...

Embodiment 2

[0095] A toilet cover containing rice husk and wood flour, the toilet cover is made of a mixture by hot pressing, and the mixture includes the following raw materials in parts by weight:

[0096] 40 parts rice husk

[0097] 40 parts wood flour

[0098] 12 parts of urea-formaldehyde glue.

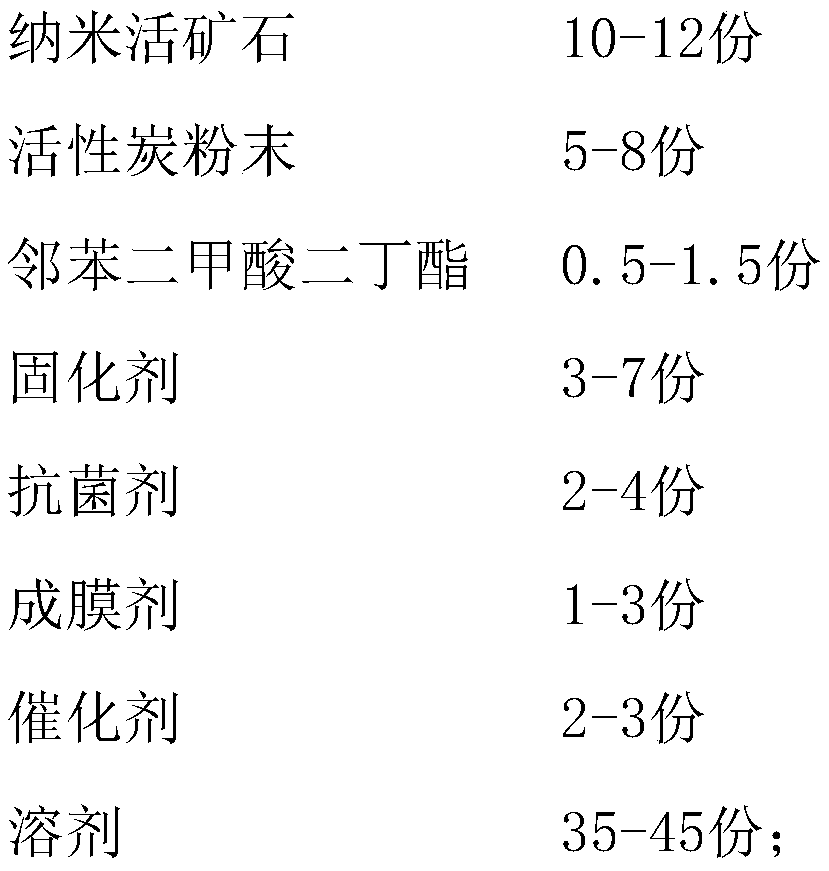

[0099] Described urea formaldehyde glue comprises the raw material of following weight portion:

[0100]

[0101] Described urea-formaldehyde glue is made by following steps:

[0102] Step A: According to parts by weight, add formaldehyde into the reaction vessel, heat up to 36°C, add 26% sodium hydroxide by volume to adjust the pH value to 8.3, then add melamine and 26% of the total urea consumption while stirring urea, the temperature was raised to 83°C within 42 minutes during the stirring process, and after the addition was completed, the heat preservation reaction was carried out for 32 minutes, and then the temperature was lowered to 52°C to obtain material A;

[0103] Step B: a...

Embodiment 3

[0130] A toilet cover containing rice husk and wood flour, the toilet cover is made of a mixture by hot pressing, and the mixture includes the following raw materials in parts by weight:

[0131] Rice husk 50 parts

[0132] 5 parts wood flour

[0133] 15 parts of urea-formaldehyde glue.

[0134] Described urea formaldehyde glue comprises the raw material of following weight portion:

[0135]

[0136] Described urea-formaldehyde glue is made by following steps:

[0137] Step A: Add formaldehyde into the reaction vessel in parts by weight, heat up to 37°C, add 28% sodium hydroxide by volume to adjust the pH to 8.5, then add melamine and 28% of the total urea consumption while stirring urea, the temperature was raised to 83.5°C within 45 minutes during the stirring process, and after the addition was completed, the heat preservation reaction was carried out for 35 minutes, and then the temperature was lowered to 55°C to obtain material A;

[0138] Step B: adding ammonium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap