A device for drilling deep holes on the side wall of a pipeline

A technology for drilling depth and pipeline, which is applied in the field of rock mechanics model test equipment, and can solve the problems of inability to complete the drilling of the inner wall of the pipeline and insufficient automation of the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

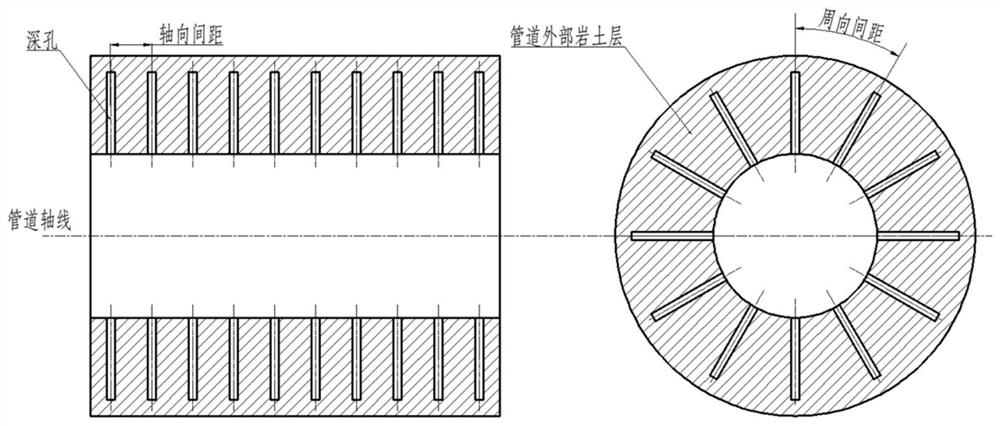

[0028] 1. A device for drilling deep holes on the side wall of a pipeline, the purpose of which is to design a drilling tool for the inner wall of a pipeline, including: a structure for realizing the overall axial movement of the drilling device, and a device for realizing the 360-degree circumferential rotational movement of the drilling device The structure realizes the stable tie rod support structure of the front end device of the drilling tool positioned on the inner wall of the pipeline, realizes the front end drill device capable of drilling deep holes and the radial advance and retreat structure, and the synchronous belt pulley and the universal coupling and the bevel gear cooperate. Power transmission system and vision transmission device. The tight cooperation between the above-mentioned parts constitutes a tool for drilling deep holes on the inner wall of the sizing pipeline.

[0029] 2. Since the pipeline is narrow and long, in order to ensure that the drilling too...

Embodiment 2

[0035] The invention relates to a device for drilling deep holes on the side wall of a pipeline, and its purpose is to design a tool capable of drilling deep holes on the inner side wall of a long and narrow pipeline. The pre-experimental devices used in trenchless pipelines, coal and rock exploration, mining and other fields have important scientific significance for promoting the development of rock mechanics, trenchless work inside pipelines, and the construction of experimental platforms for simulating tunnel bolting.

[0036] The purpose of the present invention is achieved like this:

[0037] It includes: a structure to realize the overall axial movement of the drilling device; a structure to realize the 360-degree circumferential rotation of the drilling device; a stable tie rod support structure and a power transmission system to realize the positioning of the front end of the drilling tool on the inner wall of the pipeline; The front-end drill device and power transmi...

Embodiment 3

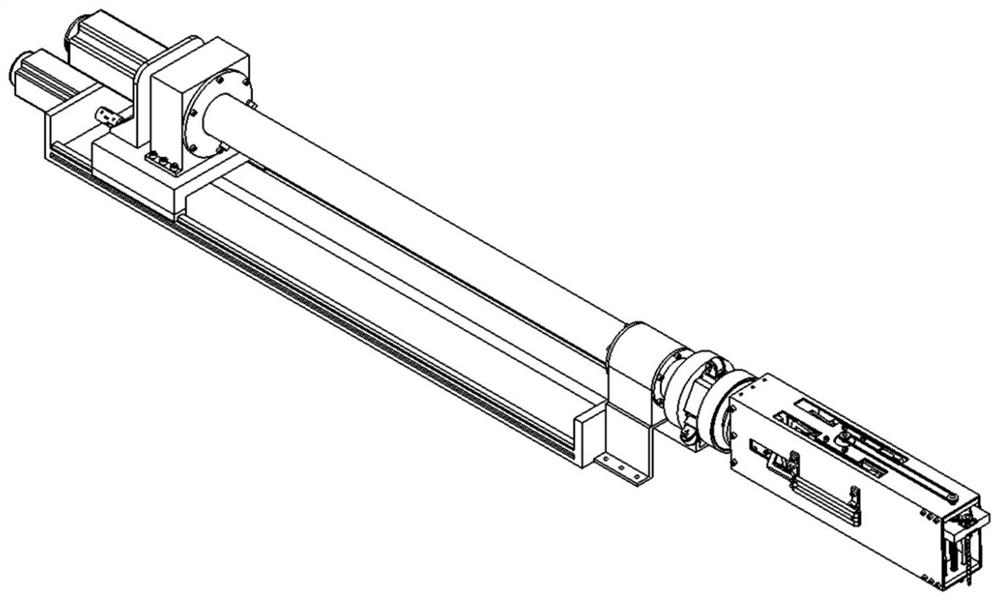

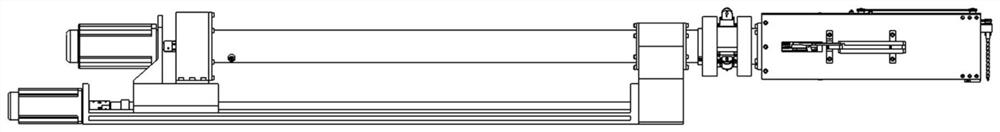

[0041] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 shown.

[0042] A device for drilling deep holes on the side wall of a pipeline mainly includes: a first AC servo stepping motor 1, a first coupling 2, a large screw 3, a large screw slide base 4, a large slide plate 5, and a second AC Servo stepper motor 6, stepper motor bracket 7, second coupling 8, large slide bearing seat 9, thrust bearing 10, first PTFE sleeve 11, main shaft connector 12, large slide end cover 13, main shaft 14. Support leg 15, ball cage seat 16, cage left end cover 17, ball cage 18, cage right end cover 19, limit snap ring 20, left angular contact ball bearing 21, road wheel bearing seat 22, road wheel Seat 23, walking wheel 24, right angular contact ball bearing 25, cylindrical flange 26, fixed connector 27, reduction motor support 28, worm gear reduction motor 29, square tube 30, support gear 31, support rack 32, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com