High-range acceleration sensor ceramic silicon ceramic three-layer leadless package structure

A technology of acceleration sensor and packaging structure, which is applied in the direction of measuring acceleration, speed/acceleration/shock measurement, measuring device, etc. It can solve the problems of increasing the volume and reducing the reliability of the sensor, so as to reduce the volume, realize leadless packaging, The effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

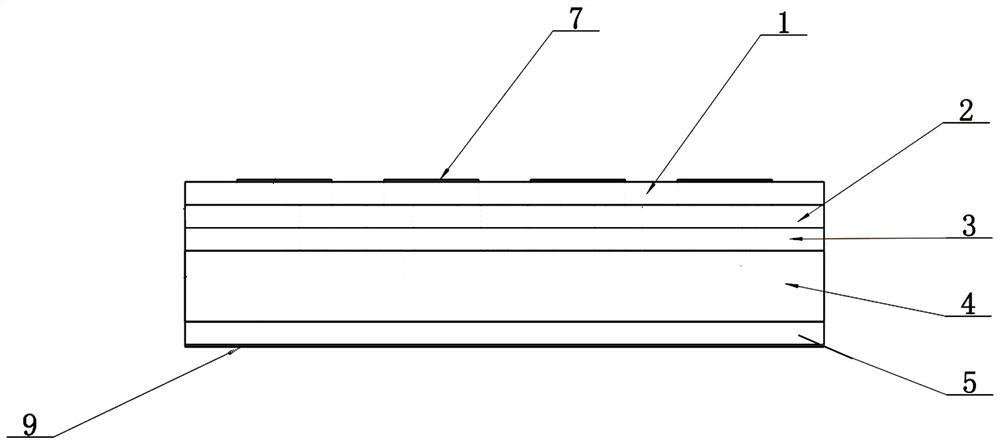

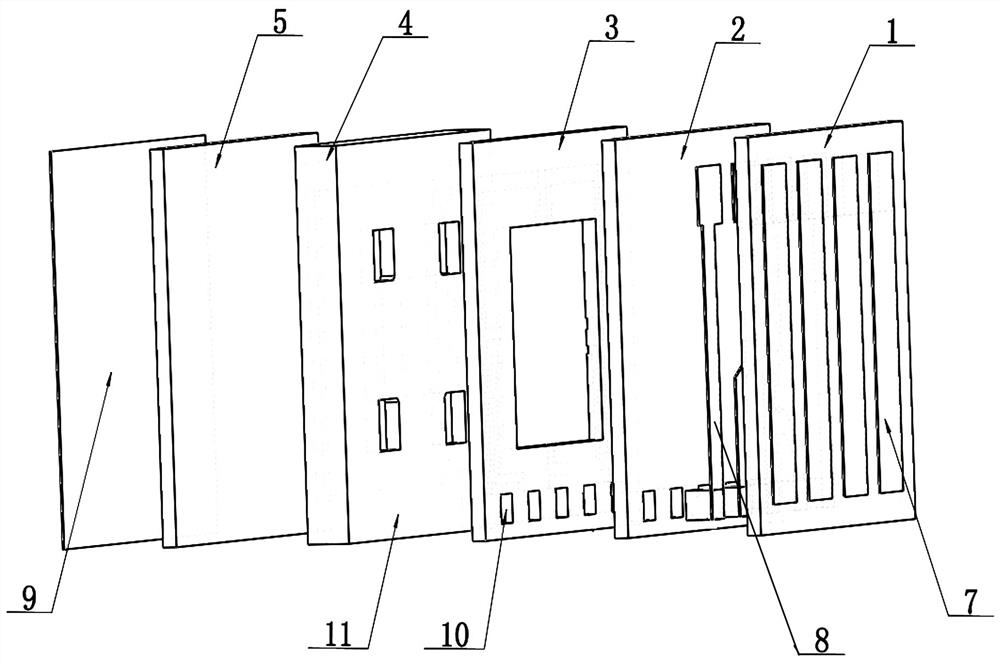

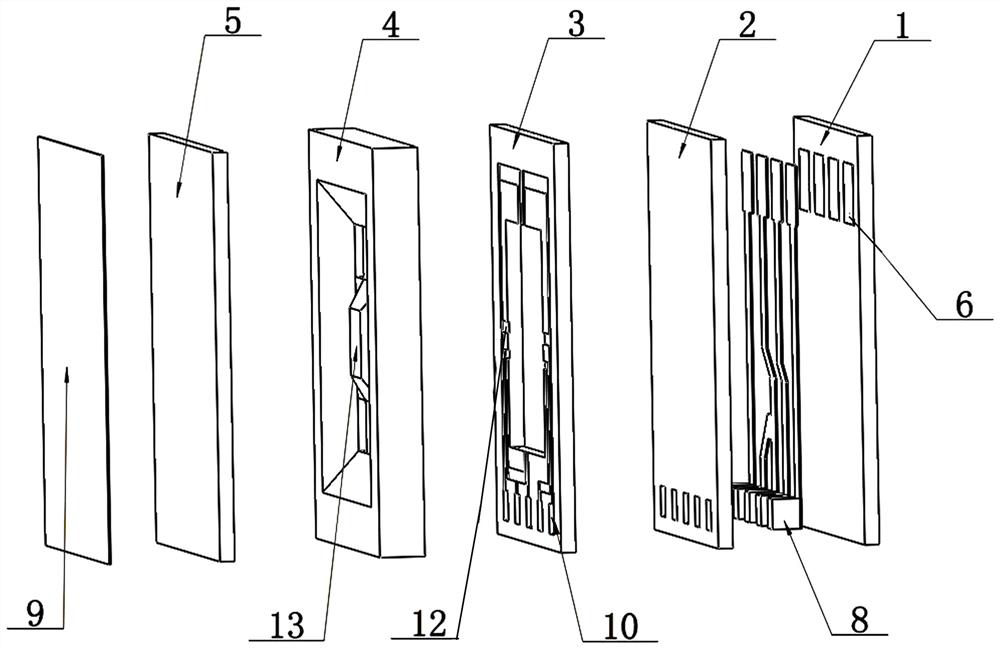

[0021] Such as Figure 1-Figure 3 As shown, a high-range acceleration sensor ceramic silicon ceramic three-layer leadless packaging structure includes a bottom layer of cooked ceramic chip 5, a sensitive structure 4, a third layer of cooked ceramic chip 1, a second layer of cooked ceramic chip 2, a first layer of cooked ceramic chip Ceramic sheet 3, the bottom surface of the bottom cooked porcelain sheet 5 is brushed with brazing paste 9, and the top surface of the bottom cooked porcelain sheet 5 is bonded to the back of the sensitive structure 4 using anodic bonding technology. The front side of the sensitive structure 4 is also bonded to the three-layer cooked porcelain sheet by anodic bonding technology, and the three-layer cooked porcelain sheet is respectively the first layer of cooked porcelain sheet 3 and the second layer of cooked porcelain sheet arranged from bottom to top. Sheet 2 and the third layer of cooked porcelain sheet 1, wherein the first layer of cooked porc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com