Extraction method of selenium-rich moringa oleifera

An extraction method and selenium-enriched technology, applied in organic chemistry and other directions, can solve the problems of reduced polysaccharide purity and yield, leaf thickness, weakened photosynthesis, resource waste, etc., to reduce energy consumption and nutrient loss, combination rate and The effect of high utilization rate and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

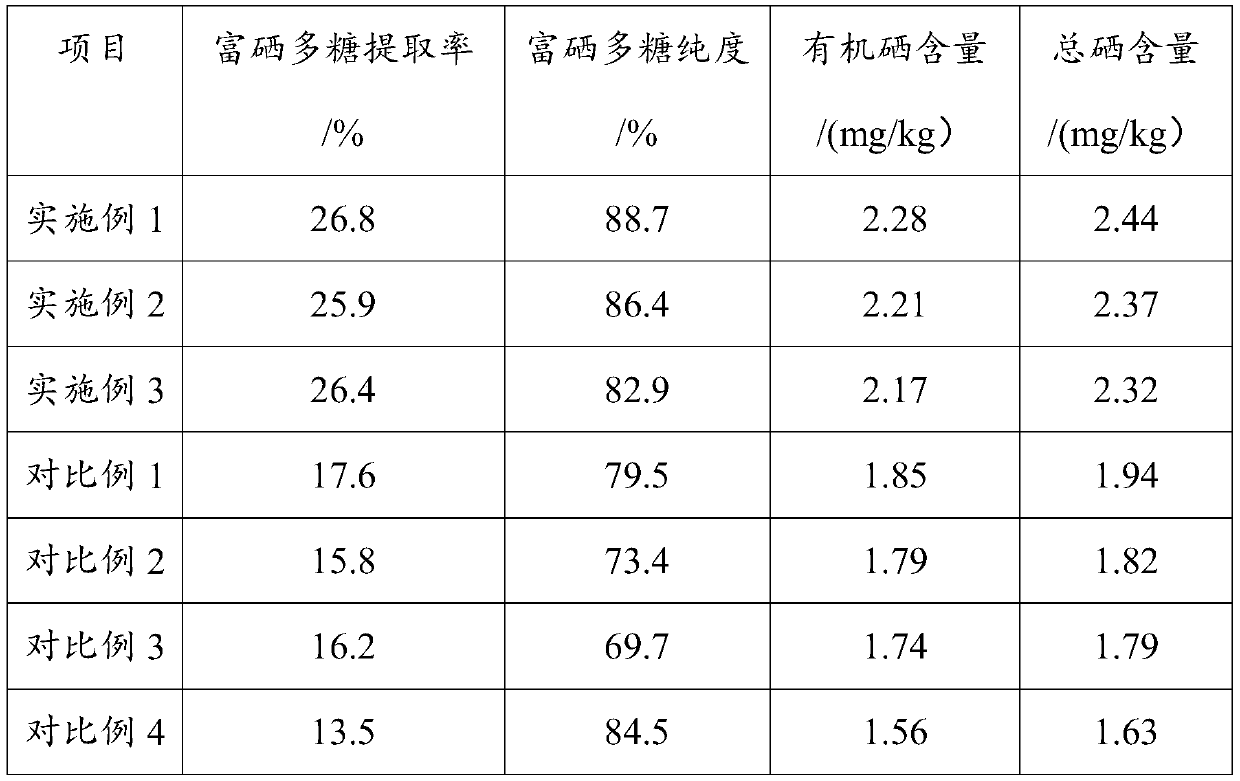

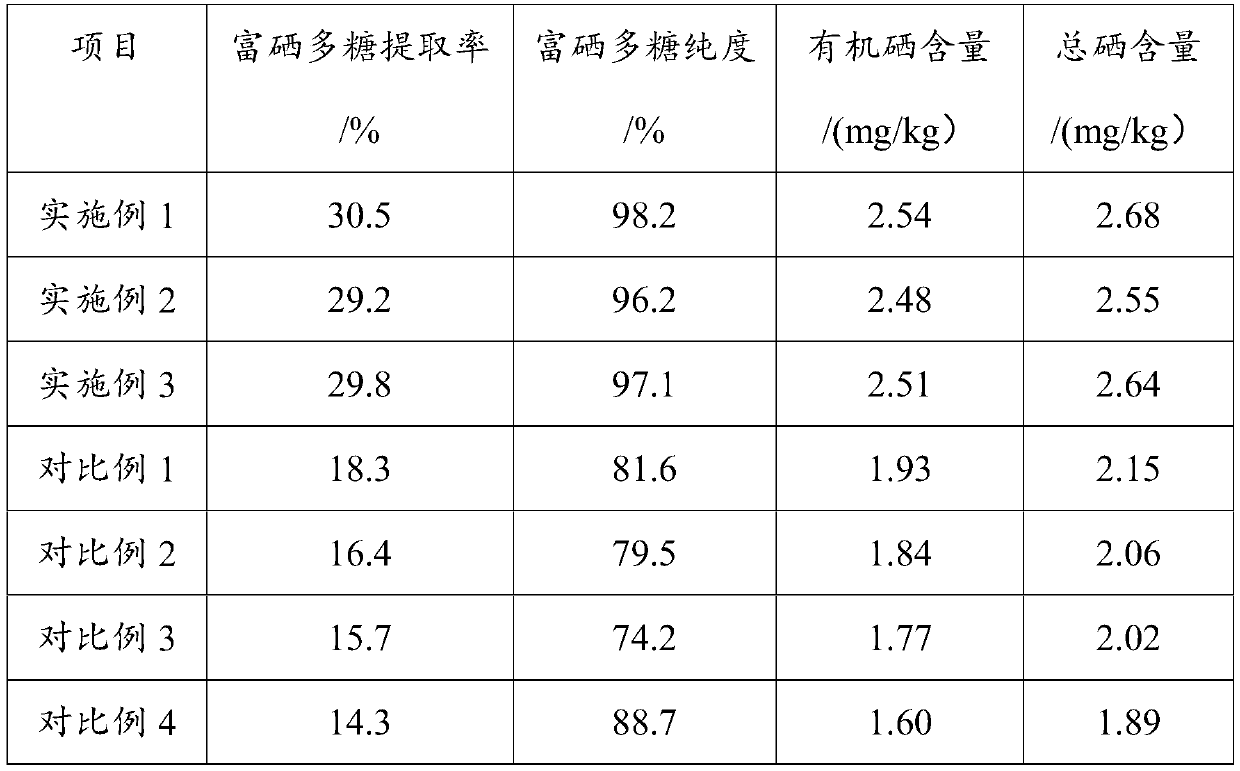

Examples

Embodiment 1

[0040] The extraction method of present embodiment selenium-enriched Moringa, comprises the following steps:

[0041] (1) Raw material selection and pretreatment: select the young leaves and petioles of selenium-enriched Moringa oleifera cultivated in selenium-enriched nutrient solution, remove surface dust particles by vacuum vibration, and spray diatomaceous earth on the surface of young leaves and petioles. After the water is vaporized, continue to spray the leaf nutrient, and carry out microwave drying and thermal conditioning at 80°C for 50s; wherein, the preparation method of the selenium-enriched nutrient solution is as follows: select organic selenium as the selenium raw material, mix 100mg of organic selenium with 200kg of water, Add 20mg of yeast selenium, and keep stirring until the organic selenium is completely dissolved; the method of using selenium-enriched nutrient solution to cultivate selenium-enriched moringa is as follows: after the moringa seedlings are pla...

Embodiment 2

[0053] The extraction method of present embodiment selenium-enriched Moringa, comprises the following steps:

[0054] (1) Raw material selection and pretreatment: select the young leaves and petioles of selenium-enriched Moringa oleifera cultivated in selenium-enriched nutrient solution, remove surface dust particles by vacuum vibration, and spray diatomaceous earth on the surface of young leaves and petioles. After the water vapor, continue to spray the leaf nutrient, and carry out 56s microwave drying heat conditioning at 78°C; wherein, the preparation method of the selenium-rich nutrient solution is the same as in Example 1; use the selenium-rich nutrient solution to cultivate selenium-rich Moringa Method is identical with embodiment 1. The preparation method of the leaf nutrient is the same as in Example 1.

[0055] (2) Frozen crushing: the tender leaf blade and petiole after heat conditioning are put into the airtight chamber, feed low-temperature circulating nitrogen, w...

Embodiment 3

[0061] The extraction method of present embodiment selenium-enriched Moringa, comprises the following steps:

[0062] (1) Raw material selection and pretreatment: select the young leaves and petioles of selenium-enriched Moringa oleifera cultivated in selenium-enriched nutrient solution, remove surface dust particles by vacuum vibration, and spray diatomaceous earth on the surface of young leaves and petioles. After the water vapor, continue to spray the leaf nutrient, and carry out 50s of microwave drying heat conditioning at 82°C; wherein, the preparation method of the selenium-enriched nutrient solution is the same as in Example 1; Method is identical with embodiment 1. The preparation method of the leaf nutrient is the same as in Example 1.

[0063] (2) Frozen crushing: the tender leaf blade and petiole after heat conditioning are put into the airtight chamber, feed low-temperature circulating nitrogen, when the volume of low-temperature nitrogen reaches 62% of the airtig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com