Centralized monitoring system and method for gas alarm apparatus of iron works

A centralized monitoring and alarm technology, applied in general control systems, control/regulation systems, alarms, etc., can solve problems such as insufficient attention to alarm phenomena, gas poisoning, hidden dangers, etc., and achieve the goal of improving safety management efficiency and safety management level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

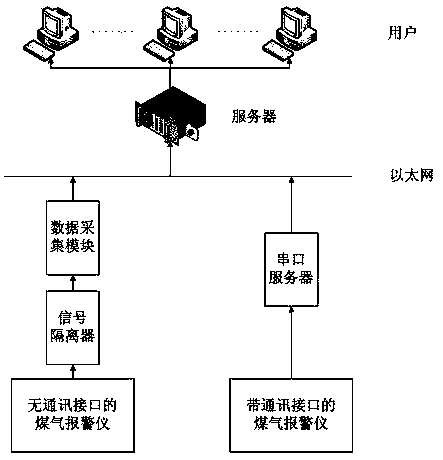

[0021] Such as figure 1 Shown, the present invention a kind of centralized monitoring system of gas alarm instrument of ironworks, comprises gas alarm instrument, data acquisition unit, switchboard, server, work station, the input end of described switchboard is connected the output end of data acquisition unit, the output end of switchboard Connect server, described server utilizes C# language to realize the reading of gas alarm instrument signal according to Modbus-TCP agreement, then data is stored in SQL Server2008 database; Described data collection unit comprises:

[0022] (2) Signal isolator and data acquisition module, wherein: the input end of the signal isolator is connected to the gas alarm instrument, which is used to collect the gas detection signal output by the gas alarm instrument without communication interface and 4-20mA standard signal output, The signal isolator sends the output signal to the data acquisition module, and the Ethernet output of the data acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com