Electrode current collector, preparation method thereof, negative electrode and lithium ion battery

A technology for electrode collectors and lithium-ion batteries, which is applied in the direction of electrode carriers/collectors, electrode manufacturing, secondary batteries, etc., can solve problems such as limited applications, reduced volumetric energy density, and reduced battery mass energy density, so as to promote Effects of application, improved circulation, and improved structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

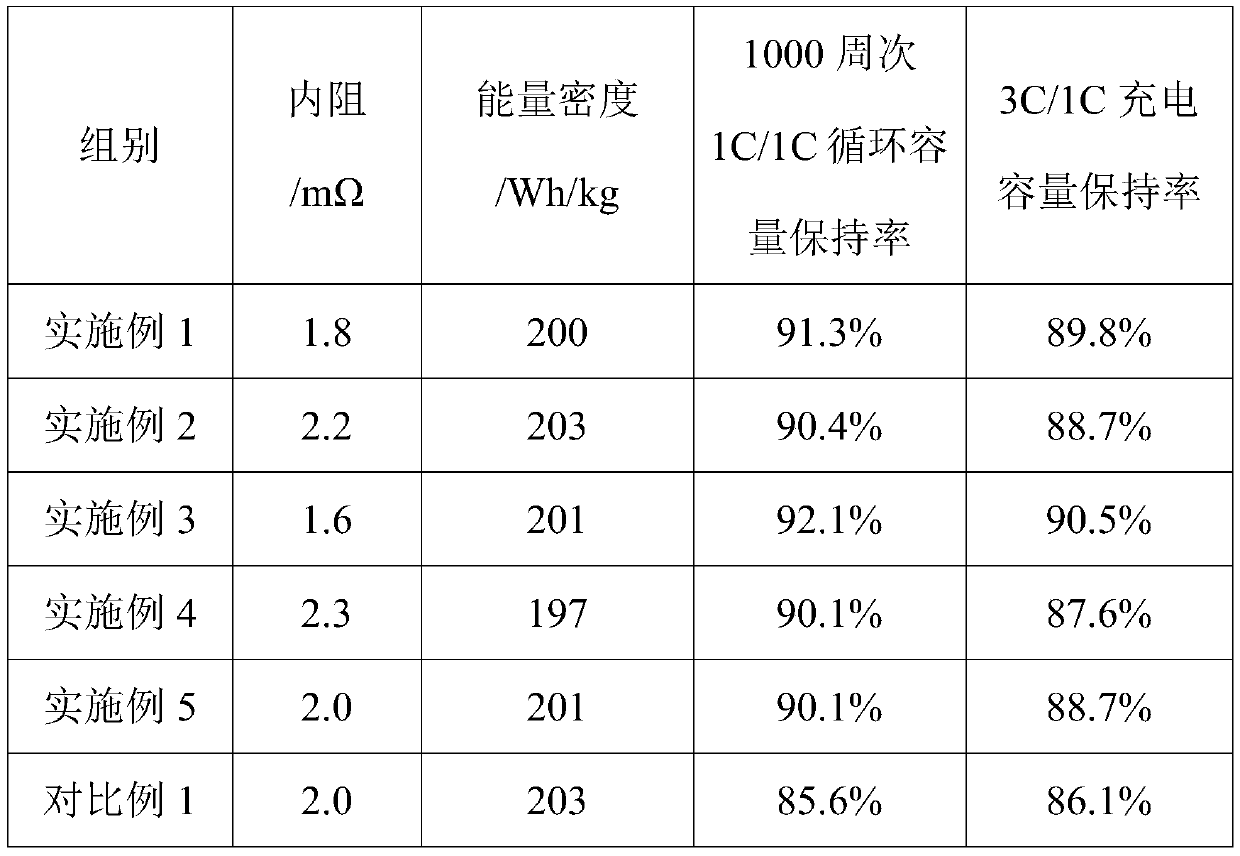

Examples

preparation example Construction

[0023] One embodiment of the present invention provides an electrode current collector and a preparation method thereof. The electrode current collector will be introduced in conjunction with the preparation method below. The preparation method of the electrode current collector comprises the following steps S1-S4:

[0024] Step S1, mixing the silicone rubber and curing agent to obtain a mixed slurry.

[0025] In one embodiment, the silicone rubber is polydimethylsiloxane (PMDS); the curing agent is a polycondensation-type two-component silicone rubber crosslinking agent, such as a curing agent modeled as RTV-2. Further, the mass ratio of the silicone rubber to the curing agent is 10:(0.5-2). Furthermore, the mass ratio of the silicone rubber to the curing agent is 10:1.

[0026] Step S2, coating the mixed slurry on the porous substrate, and curing to form a silicone rubber layer.

[0027] Specifically, the pore diameter of the porous matrix in step S2 is 1 μm-5 μm, and th...

Embodiment 1

[0044] Firstly, the copper foil with a thickness of 8 μm is punched by mechanical processing, and the copper foil is porous; the pores are guaranteed to be uniform, the pore size is about 5 μm, and the porosity is 10%. Secondly, the liquid silicone rubber and the silicone rubber curing agent are stirred and dispersed at a mass ratio of 10:1 to obtain a mixed slurry, which is coated on one side of the prepared porous copper foil substrate with a coating thickness of 2 μm. After the coating is completed, put it in an oven and bake it at 80°C for 24 hours to obtain a PMDS coating, and then perform an opening treatment on the coating with a pore size of 2 μm and a porosity of 20%; finally, the PMDS coating surface is passed through the gas phase The deposition method sprays a certain amount of copper powder with a particle size of 50nm, fills the internal pore structure of PMDS, and forms a copper plating layer with a thickness of about 800nm, and obtains a current collector for th...

Embodiment 2

[0047] Firstly, the copper foil with a thickness of 6 μm is punched through mechanical processing to ensure that the pores are uniform, the pore size is about 5 μm, and the porosity is 12%. Secondly, the liquid silicone rubber and the silicone rubber curing agent are stirred and dispersed at a mass ratio of 10:1 to obtain a mixed slurry, which is coated on one side of the prepared porous copper foil substrate with a coating thickness of 3 μm. After the coating is completed, put it into an oven and bake at 100° C. for 24 hours to obtain a PMDS coating, and then perform a pore opening treatment on the coating, with a pore size of 1.5 μm and a porosity of 30%. Finally, a certain amount of copper powder with a particle size of 60nm is sprayed on the surface of the PMDS coating by vapor deposition method to fill the internal pore structure of PMDS, and at the same time, a copper plating layer with a thickness of about 600nm is formed, and the current collector for the negative elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com