High-voltage polymer electrolyte, high-voltage polymer lithium metal battery and preparation method of battery

A lithium metal battery and polymer technology, applied in the field of electrochemical energy storage, can solve problems such as poor contact of solid-state batteries, and achieve high energy density, improved electrochemical window, and good cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

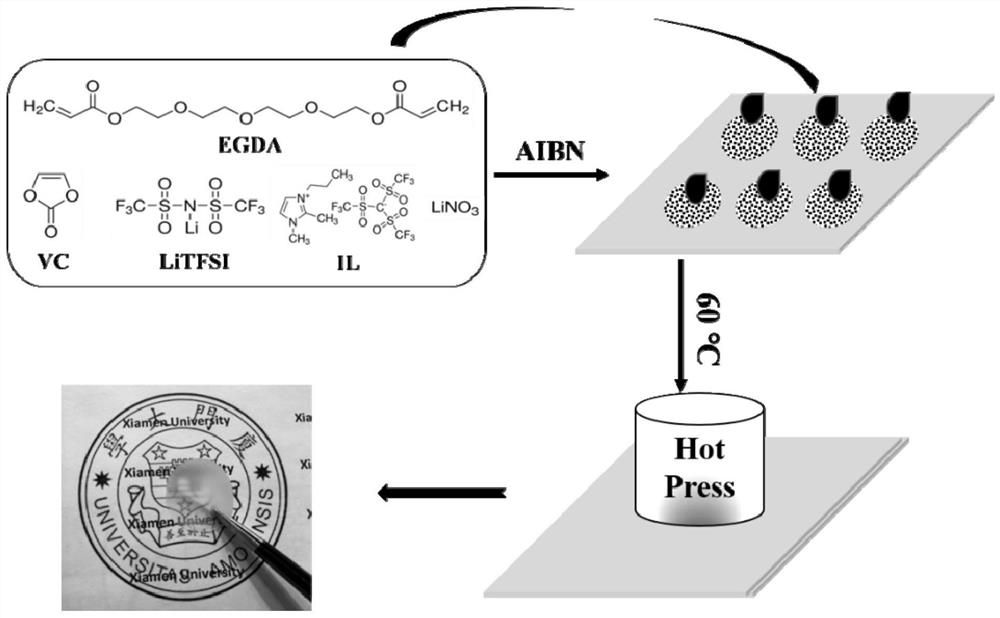

[0040] The present invention also provides a preparation method for the above-mentioned high-voltage polymer lithium metal battery compound, comprising the following steps:

[0041] S1. Mix the first monomer and the second monomer evenly, and then add the lithium salt and the ionic liquid to obtain a precursor solution.

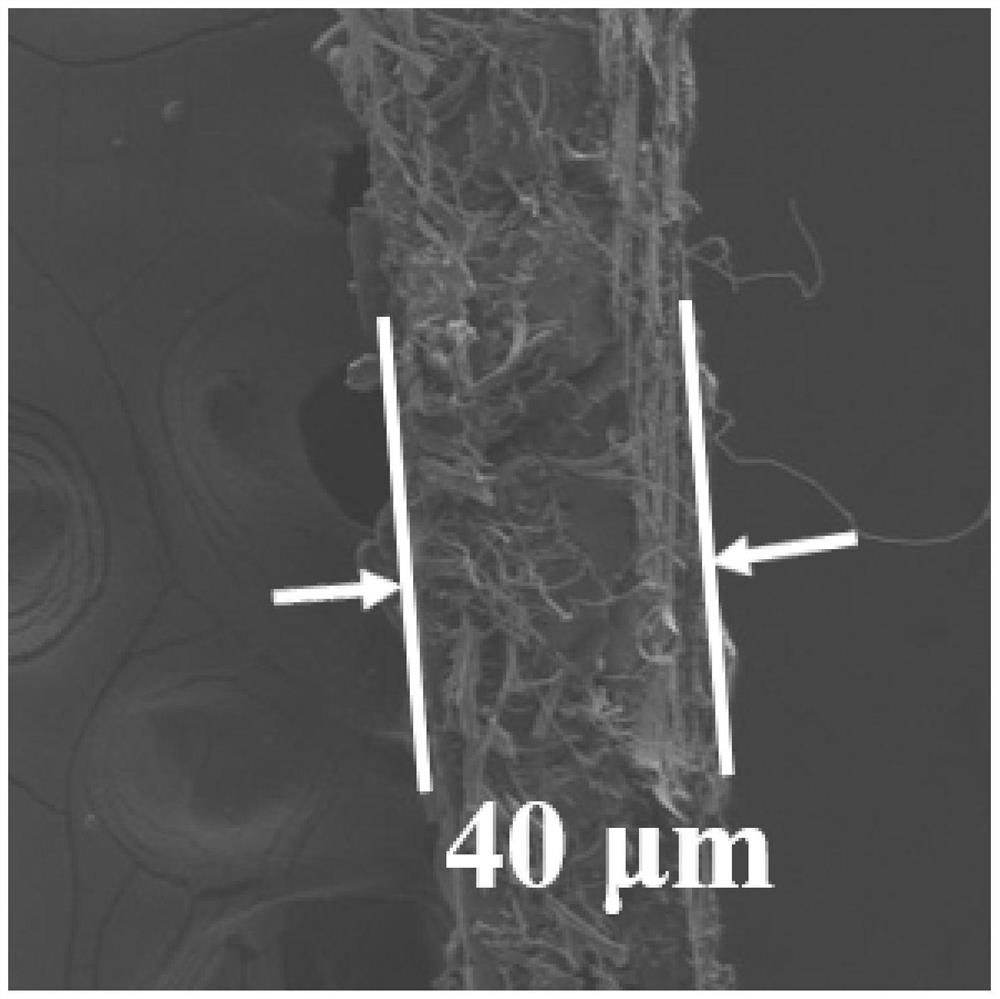

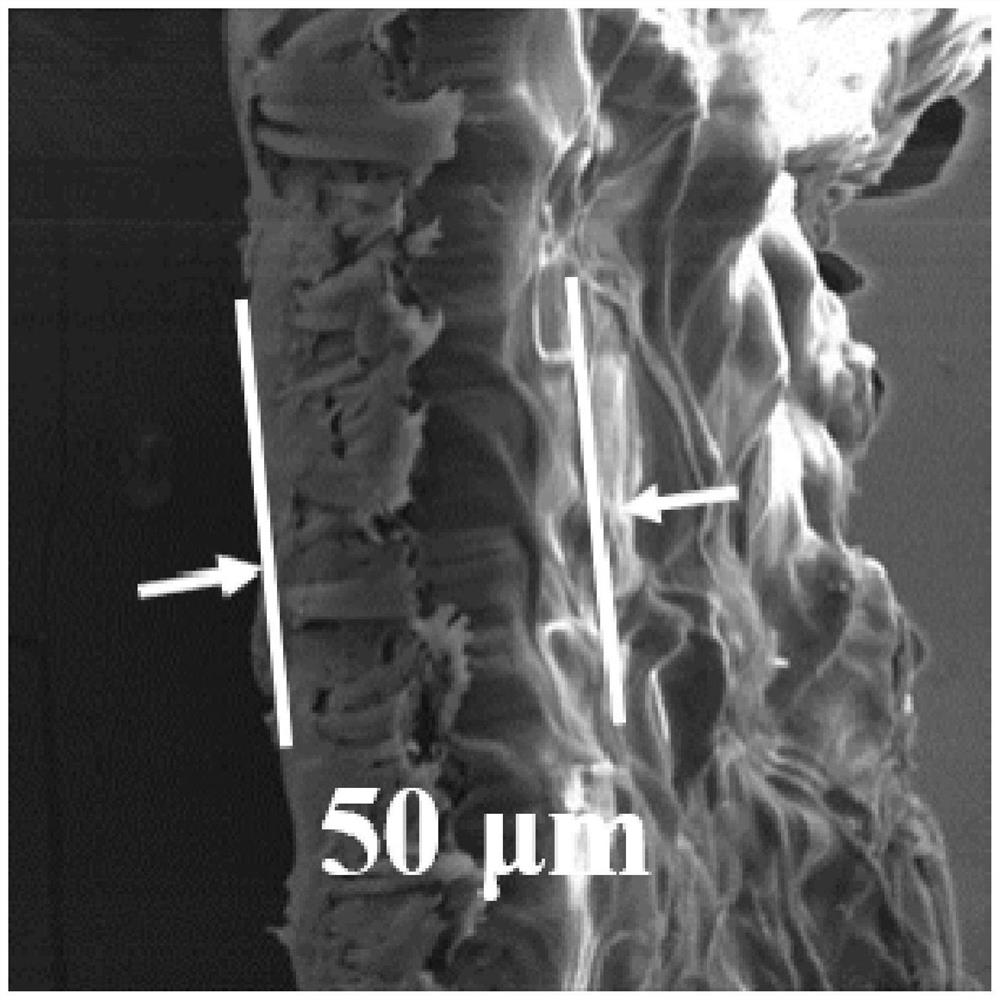

[0042] S2. Adding a thermal initiator to the precursor solution and stirring to obtain a mixed solution, and then immersing the non-woven fabric in the mixed solution to fully infiltrate it and then heating it. When cellulose non-woven fabric is used, due to the large pores of cellulose non-woven fabric, it is easy to short-circuit the positive and negative electrodes during the pressing process. , when the electrolyte is assembled with positive and negative electrodes to form a full battery, the electrolyte still has fluidity and can penetrate into the gap of the positive electrode material, thereby improving the problem of high contact resistance between th...

Embodiment 1

[0052] This embodiment provides a high-voltage polymer electrolyte and a high-voltage polymer lithium metal battery, which can be prepared according to the following steps:

[0053] First, four (ethylene glycol) diacrylate and vinylene carbonate with a molar ratio of 1:1 are mixed uniformly to obtain a polytetra(ethylene glycol) diacrylate-vinylene carbonate matrix (PVC-EGDA), and then Lithium bis(trifluorosulfonyl)imide, 1-methyl-3-butylimidazole bis(trifluoromethylsulfonyl)imide were added to the matrix of polytetra(ethylene glycol) diacrylate-vinylene carbonate[ BMI][TFSI] and LiNO 3 , to obtain the precursor solution. Wherein, the molar ratio of lithium bistrifluorosulfonyl imide to polymer monomer is 1:1. In terms of mass percent, the mass percent of 1-methyl-3-butylimidazole bis(trifluoromethylsulfonyl)imide [BMI][TFSI] in the high-voltage polymer electrolyte is 10wt.%, LiNO 3 The mass percentage in the high-voltage polymer electrolyte is 2wt.%.

[0054] After the pr...

Embodiment 2

[0057] This embodiment provides a high-voltage polymer electrolyte and a high-voltage polymer lithium metal battery, which can be prepared according to the following steps:

[0058] First, four (ethylene glycol) diacrylate and vinylene carbonate with a molar ratio of 2:1 are mixed uniformly to obtain a polytetra(ethylene glycol) diacrylate-vinylene carbonate matrix (PVC-EGDA), and then Lithium bis(trifluorosulfonyl)imide, 1-methyl-3-butylimidazole bis(trifluoromethylsulfonyl)imide were added to the matrix of polytetra(ethylene glycol) diacrylate-vinylene carbonate[ BMI][TFSI] and LiNO 3 , to obtain the precursor solution. Wherein, the molar ratio of lithium bistrifluorosulfonyl imide to polymer monomer is 1:1. In terms of mass percent, the mass percent of 1-methyl-3-butylimidazole bis(trifluoromethylsulfonyl)imide [BMI][TFSI] in the high-voltage polymer electrolyte is 10wt.%, LiNO 3 The mass percentage in the high-voltage polymer electrolyte is 2wt.%.

[0059] After the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com