Metal lithium strip with porous solid electrolyte layer and preparation method of metal lithium strip

A technology of solid electrolyte and metal lithium, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of destroying the solid electrolyte layer, physical failure, and inapplicability, so as to inhibit the growth of lithium dendrites, broaden the application range, and protect the immune system. to the damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

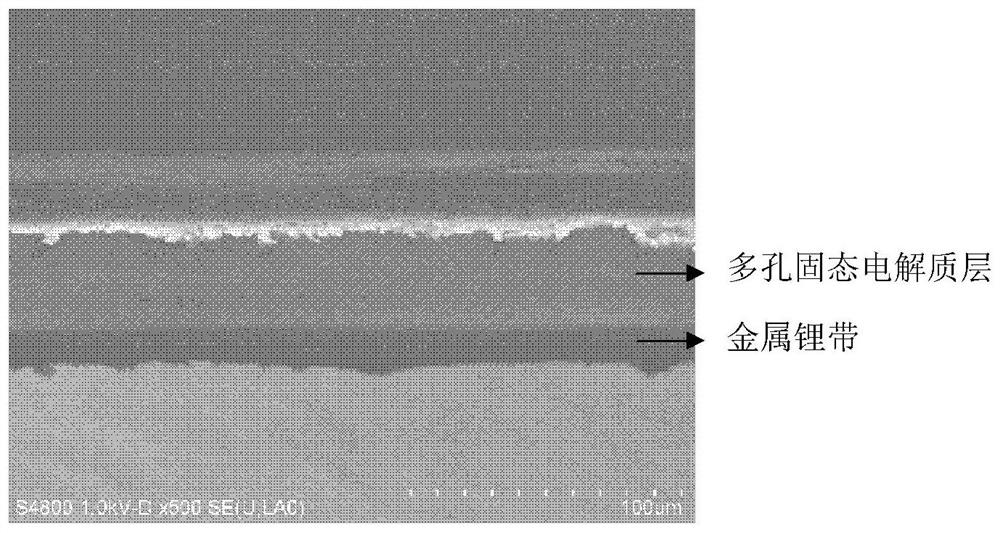

[0047] In a fume hood, polyethylene glycol was used as the organic polymer, sodium bicarbonate as the thermally decomposable inorganic salt and Li 9 N 2 Cl 3 (mix 2 moles of Li according to the chemical formula 3 N and 3 moles of LiCl were obtained by ball milling) as polyhalogen lithium metal salts. In a beaker, they were added to a tetrahydrofuran solution in a ratio of 15:35:50 by mass to obtain a solid content of 30%. gel solution, and the viscosity of the gel solution was 300 mPa·s detected by NDJ-8S digital viscometer.

[0048] Next, the gel solution obtained above was uniformly sprayed on a commercially available metal lithium tape with a thickness of 20 μm using a spray gun.

[0049] Finally, in a blast drying oven, the coated metal lithium strip was left to stand and dried, wherein the baking temperature was 45° C. and the baking time was 4 hours, thereby obtaining metal lithium with a porous solid electrolyte layer. bring.

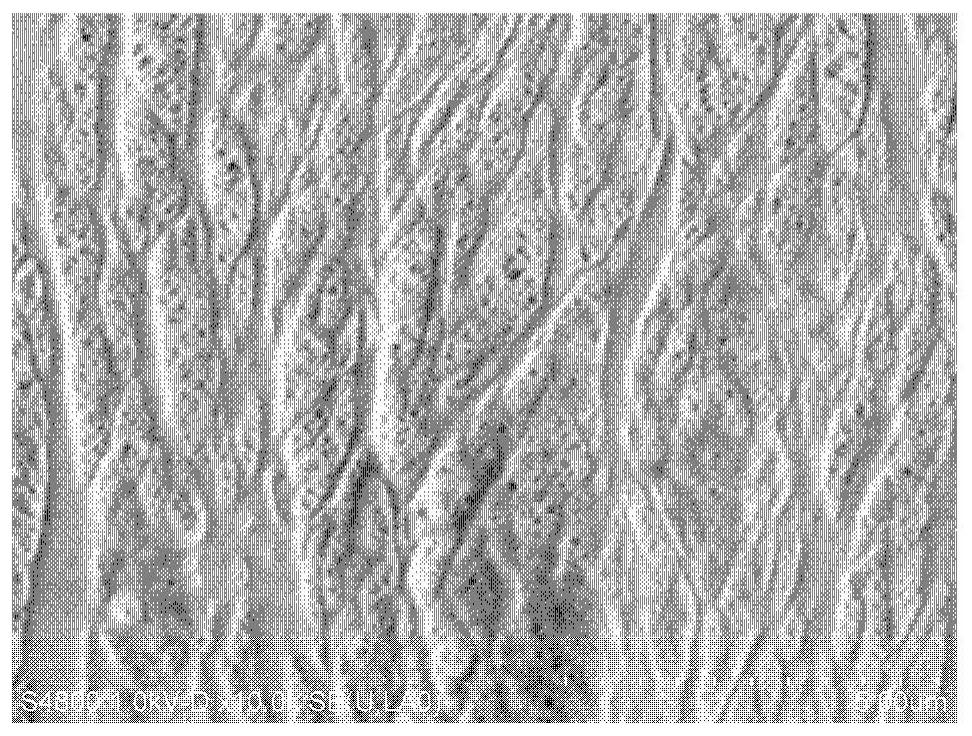

[0050] figure 1 A schematic diagram ...

Embodiment 2

[0055]Except that polyvinyl alcohol was used instead of polyethylene glycol, other steps were the same as in Example 1 to obtain a metal lithium ribbon with a porous solid electrolyte layer. After testing, its microscopic morphology and pore structure are basically the same as those in Example 1.

Embodiment 3

[0057] Except for using guar gum instead of polyethylene glycol, other steps are the same as in Example 1 to obtain a metal lithium ribbon with a porous solid electrolyte layer. After testing, its microscopic morphology and pore structure are basically the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com