A potential energy-driven material separation and transmission direct methanol fuel cell and its working method

A methanol fuel cell and methanol technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of difficult methanol fuel cell performance, uneven methanol concentration distribution, and reduced cell efficiency, etc., and achieves stable and efficient cell reaction. Utilize and improve the effect of battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

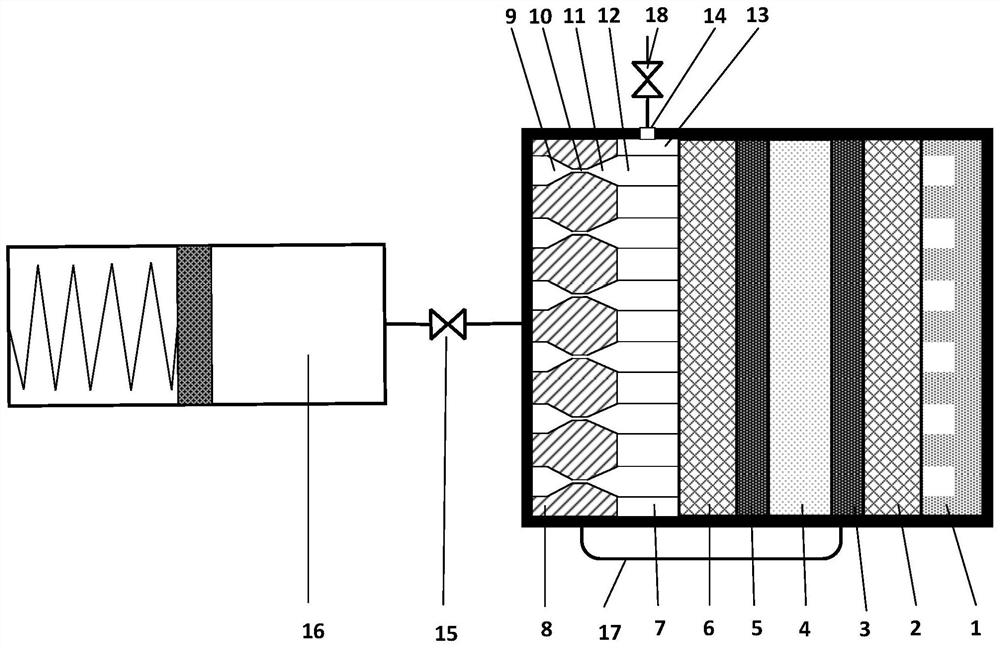

[0049] see figure 1 and figure 2 The potential energy-driven material separation and transmission direct methanol fuel cell of the present invention includes a methanol fuel cell body and a cathode flow field plate 1, a cathode diffusion layer 2, a cathode catalytic layer 3, a diaphragm 4, and an anode catalytic layer 5 arranged on the methanol fuel cell body. , anode diffusion layer 6, fuel product separation zone 7 and methanol evaporation zone 8; wherein diaphragm 4 is connected with cathode catalytic layer 3 and anode catalytic layer 5, cathode diffusion layer 2 is connected with cathode flow field plate 1 and cathode catalytic layer 3, anode The diffusion layer 6 is connected to the anode catalytic layer 5 and the fuel product separation zone 7 , and the fuel product separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com