A Harmless Treatment System for Papermaking Waste Residue

A technology of harmless treatment and papermaking waste residue, which is applied in papermaking, textiles and papermaking, fiber raw material treatment, etc., can solve the problems of polluting environmental resources, waste, utilization rate of polluting environmental impurities, etc., achieve uniform dispersion, increase vibration frequency, Favorable effect of screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

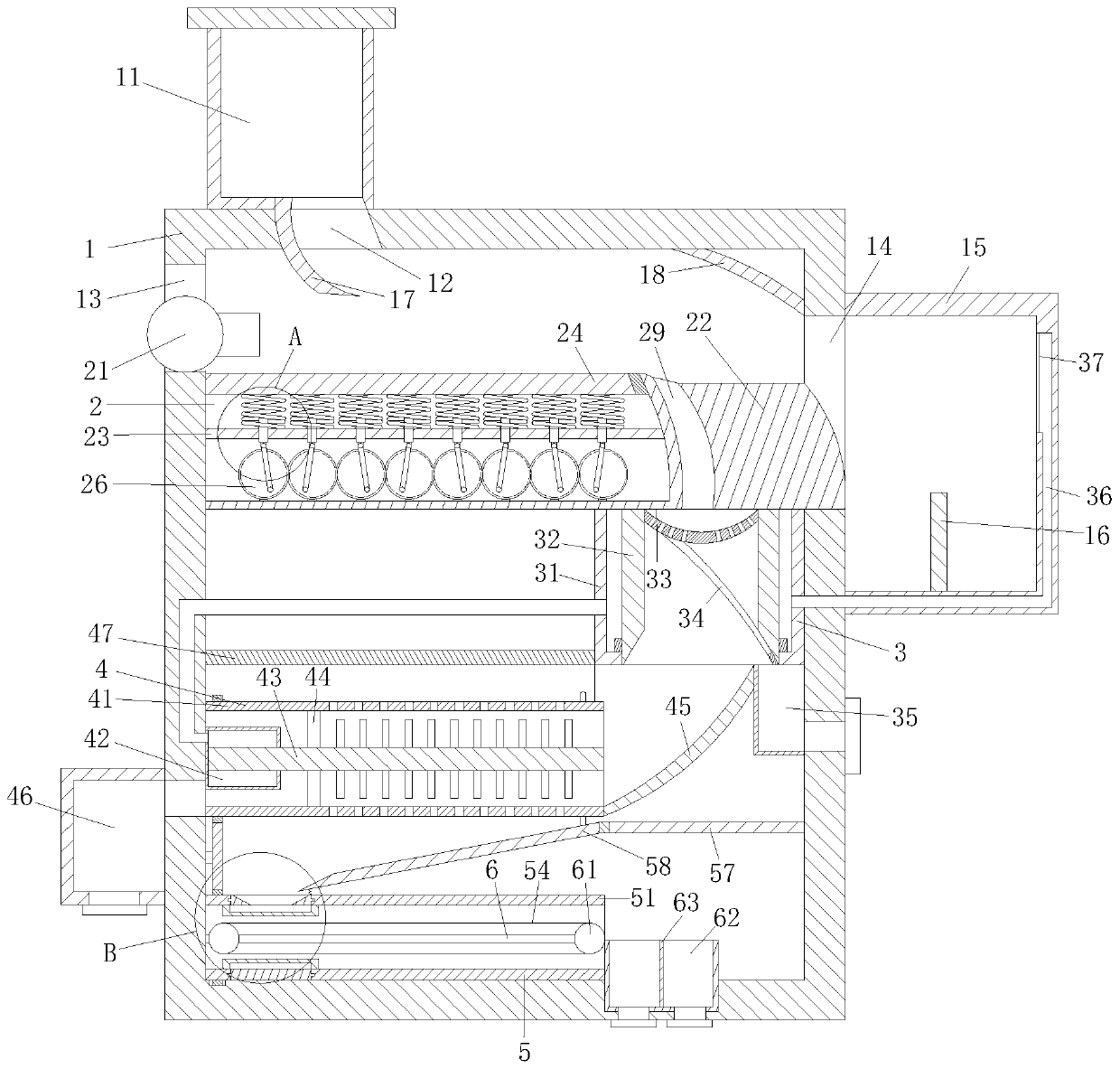

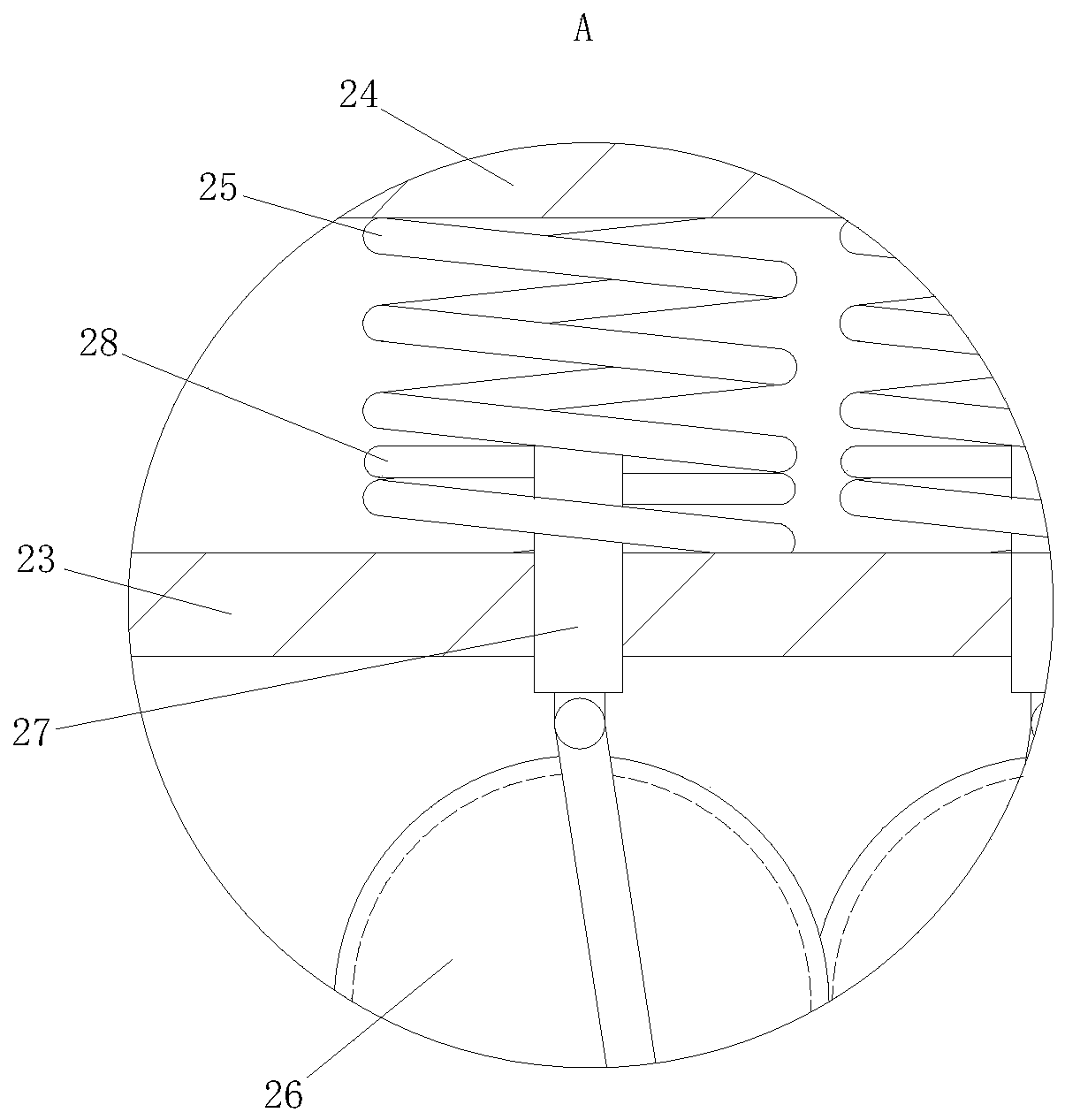

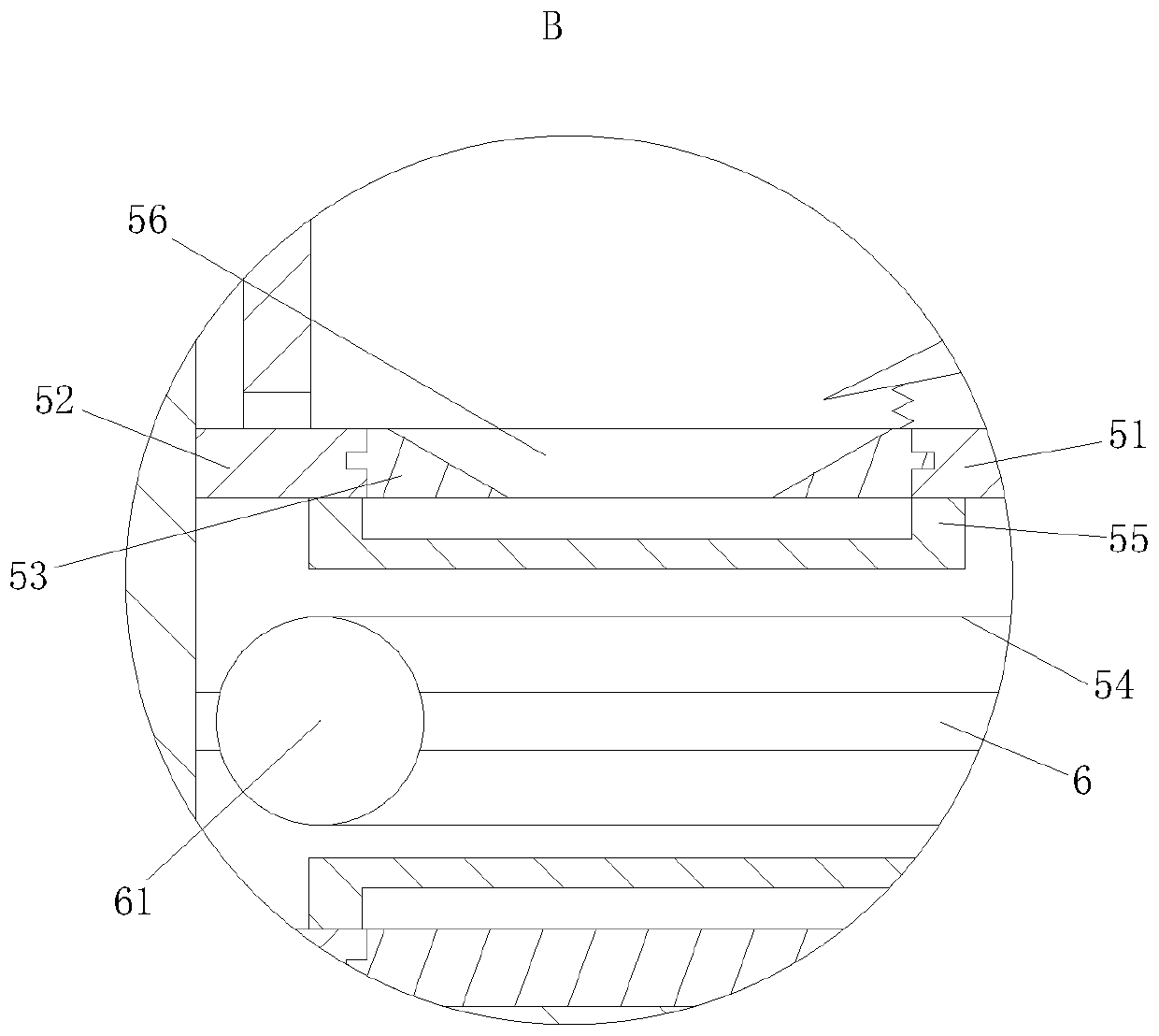

[0022] As an embodiment of the present invention, the wind vibration unit 2 includes a fan 21, a first partition 22, a fixed plate 23 and a vibration plate 24; the first partition 22 is fixedly connected to the inner wall of the frame body 1; the A cavity is provided in the first partition 22; the fixed plate 23 is fixedly connected to the inner wall of the cavity; the vibrating plate 24 is fixedly connected to the upper surface of the fixed plate 23 through evenly arranged vibrating springs 25, and the left end of the vibrating plate 24 passes The elastic rubber block is fixedly connected to the inner wall of the cavity, which can improve the vibration effect of the vibrating plate 24; a row of evenly arranged rotating shafts 26 is connected in rotation in the cavity, and the rotating shafts 26 are made of gears and mesh with each other, and one of the rotating shafts 26 Going out of the frame body 1 is driven by a motor, and the rotating shaft 26 is set in one-to-one correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com