Method for producing calcium orthophosphate and high-purity gypsum by using hydrochloric acid and phosphate rock

A technology of calcium phosphate and hydrochloric acid, applied in chemical instruments and methods, phosphorus compounds, calcium/strontium/barium sulfate, etc., can solve problems such as waste of resources, affect sustainable development, etc. The effect of investment, low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

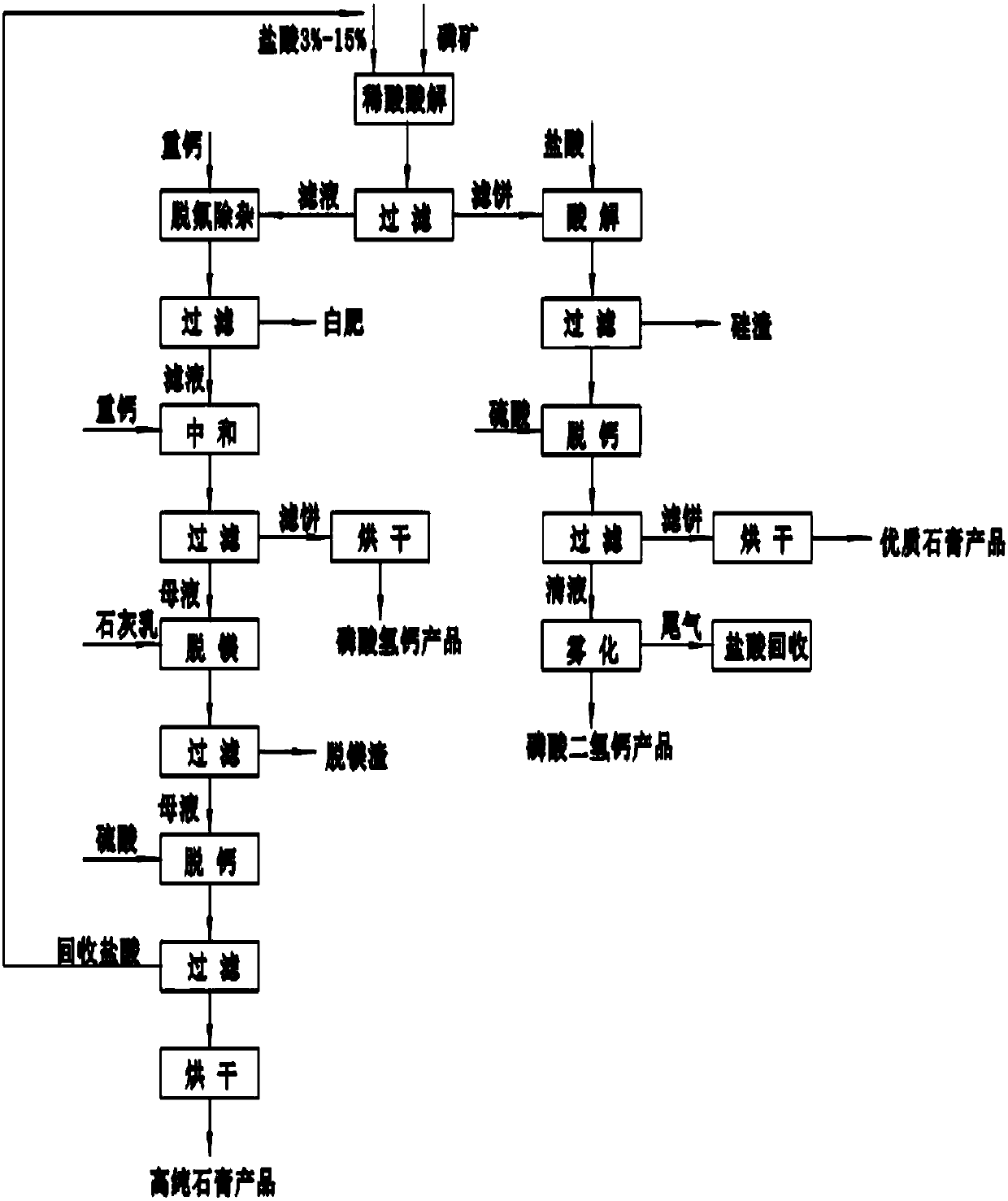

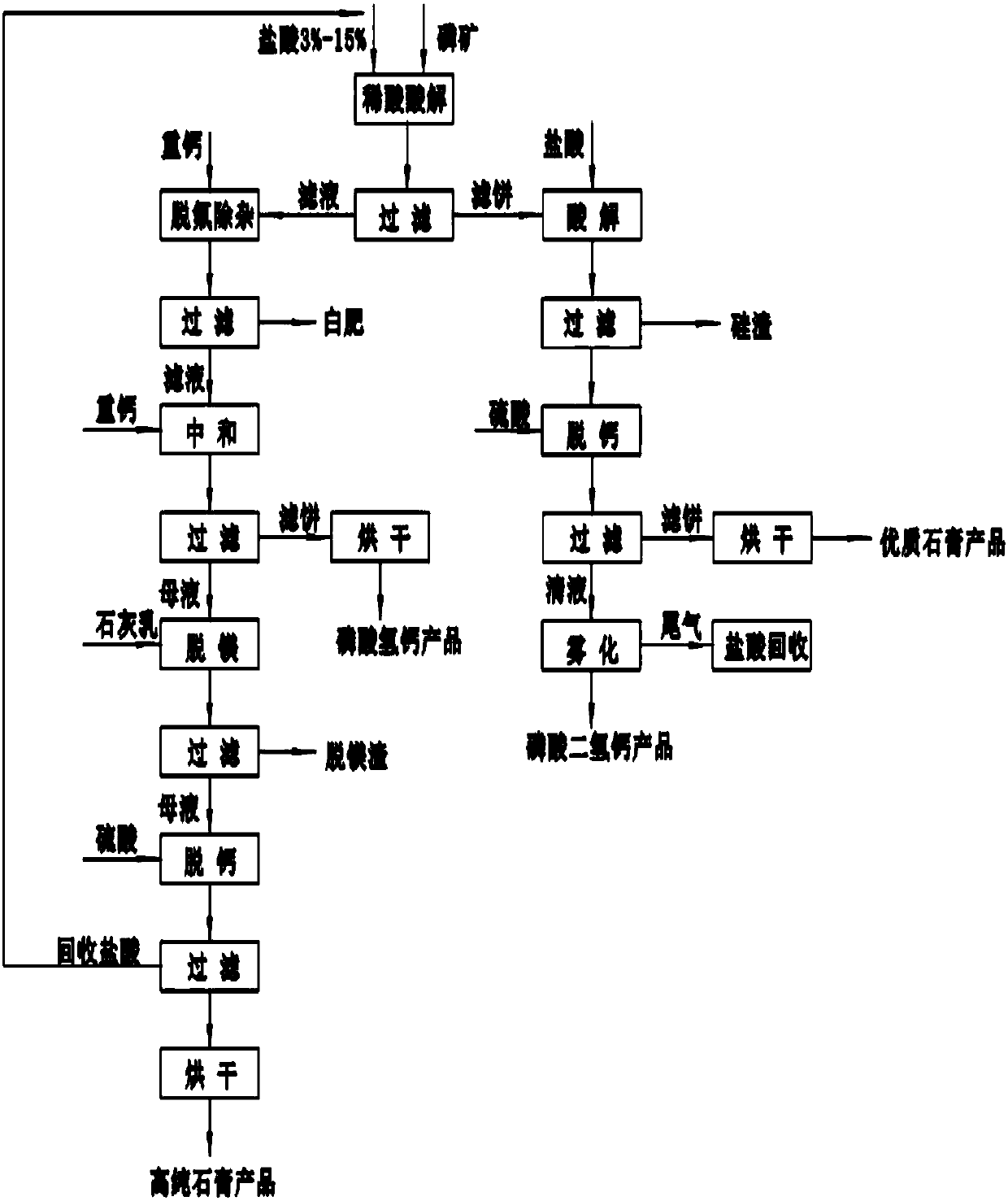

Image

Examples

Embodiment 1-4

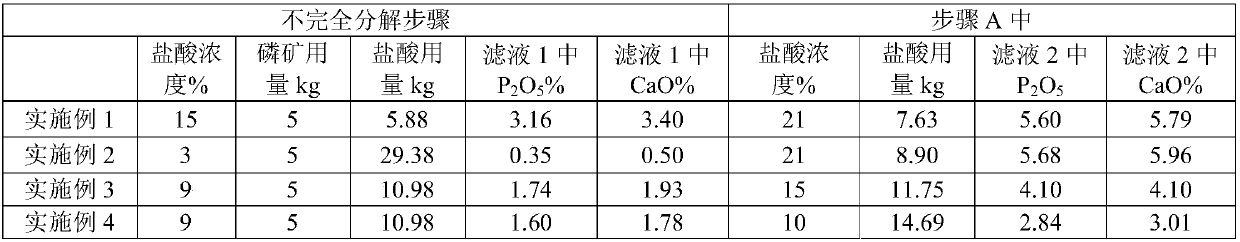

[0062] Table 1 below selects phosphate rock, and Table 2 below controls the ratio of raw materials in each step. Decompose the phosphate rock with hydrochloric acid for 30 minutes, filter and separate to obtain filter cake 1 and filtrate 1;

[0063] Step A: add hydrochloric acid to decompose the filter cake 1, calculate the amount of hydrochloric acid added according to the CaO in the filter cake 1, thicken and separate after 30 minutes of reaction, return the slurry to the acid leaching part and react with the thick slurry again, the filtrate 2 contains calcium ions, Phosphate ion, according to the P 2 o 5 / CaO Add additional sulfuric acid to precipitate to obtain calcium sulfate, wash to obtain high-quality gypsum, and the remaining liquid is defluorinated, dechlorinated, and dehydrated by atomization to obtain qualified calcium dihydrogen phosphate products.

[0064] Step B, add alkaline calcium salt to the filtrate 1 to control the pH to 1.2 to 2.2 for defluorination and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com