Method for determining content of fluorine in fluorine-containing liquid during tantalum and niobium hydrometallurgical process

A technology of wet smelting and determination method, which is applied in the direction of chemical analysis by titration method, etc. It can solve the problems of large deviation of sample analysis data, poor accuracy, and poor system applicability, and achieve high accuracy and reproducibility. High performance and small relative standard deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

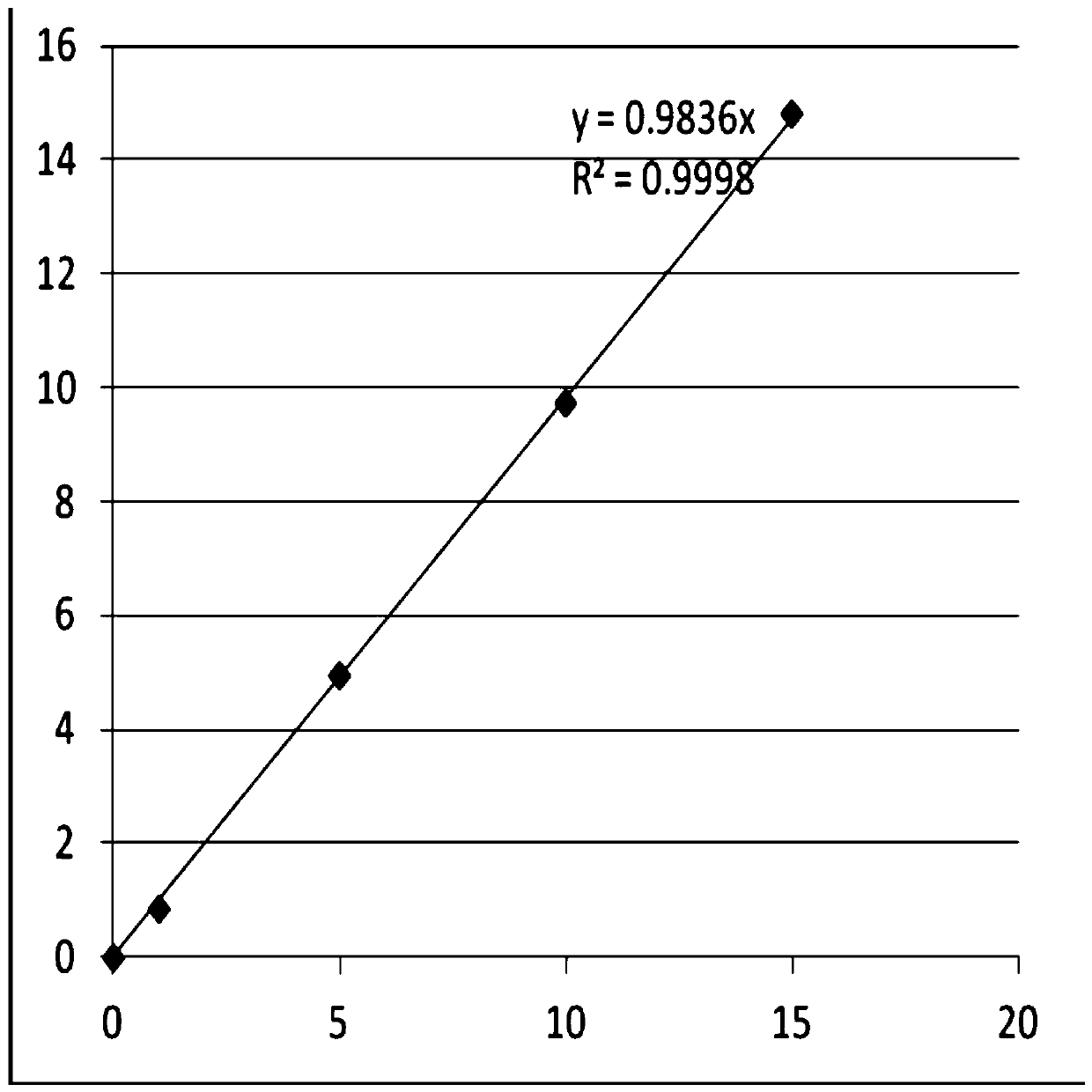

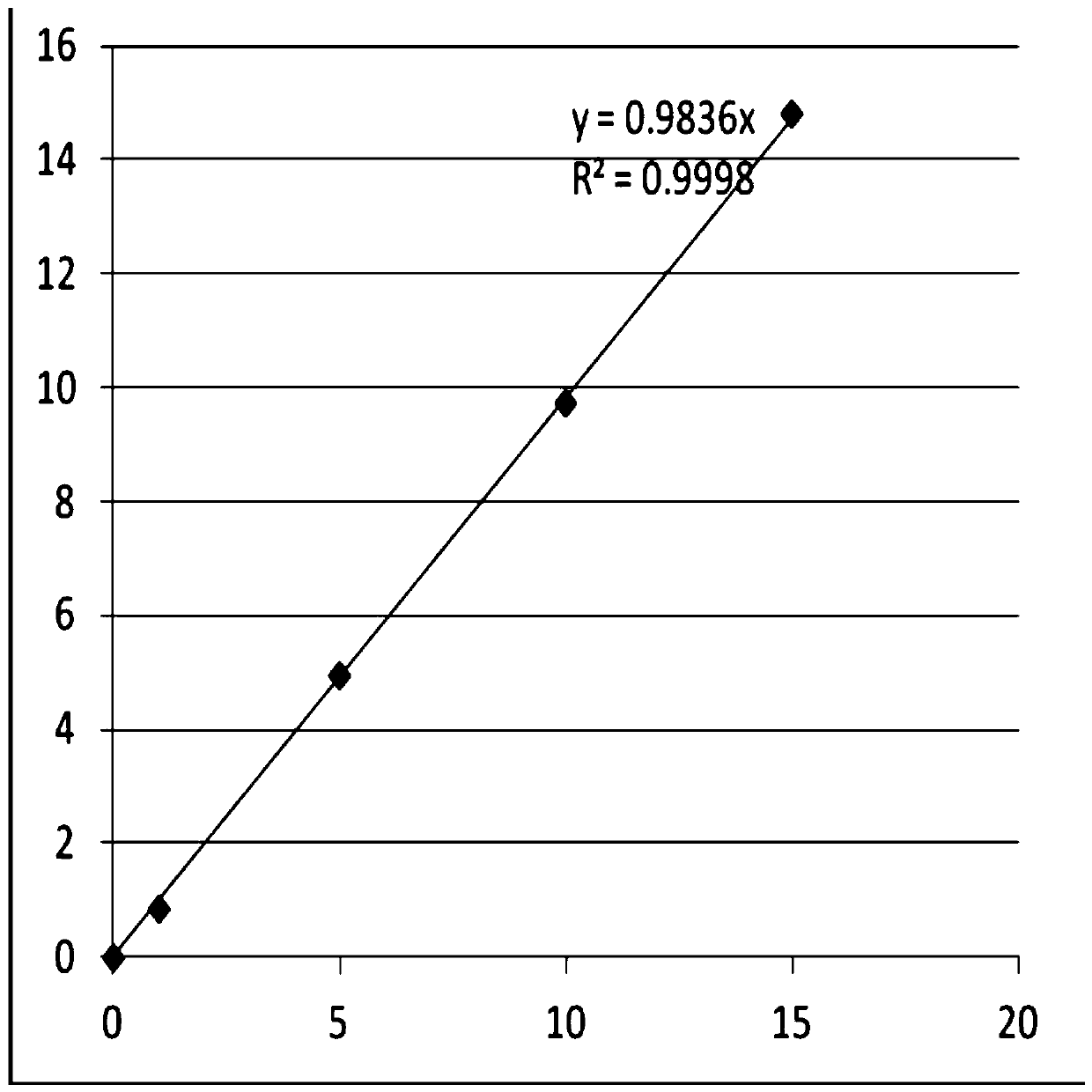

Image

Examples

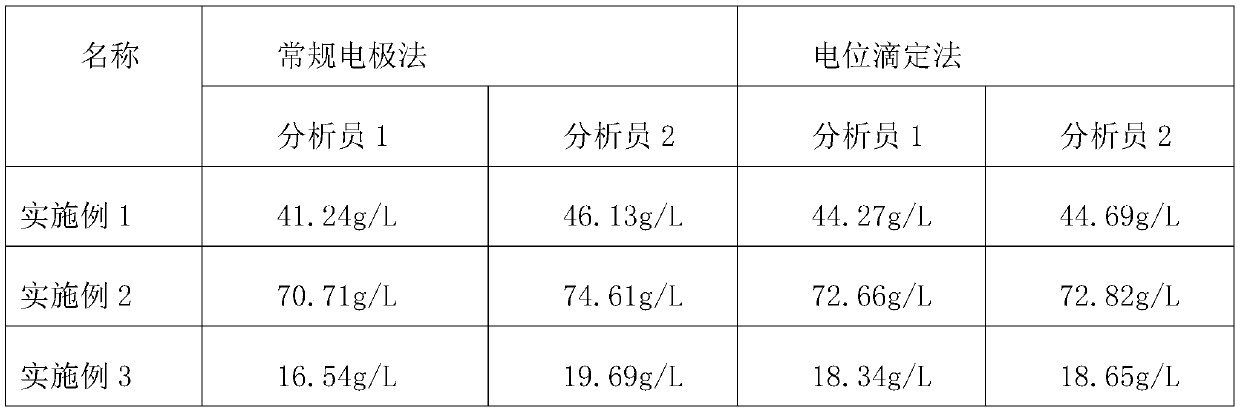

Embodiment 1

[0054] A method for measuring fluorine content in tantalum liquid, comprising the following steps:

[0055] Lanthanum nitrate solution preparation steps: Weigh 38.00g of lanthanum nitrate in a 500ml volumetric flask, dilute to 500ml with pure water, after the dissolution is complete, obtain a lanthanum nitrate solution, move the lanthanum nitrate solution to a potentiometric titration bottle, and wait for calibration;

[0056] Cleaning of the potentiometric titrator and selection of parameters: clean the pipeline of the potentiometric titrator with pure water, and operate the potentiometric titrator: power on—cleaning—confirmation, generally cleaning 3 times. After cleaning, ensure that there are no obvious air bubbles in the pipeline, such as If there are bubbles, repeat the last operation until there are no obvious bubbles in the pipeline, then use the pipeline of the lanthanum nitrate solution potentiometric titrator to repeat the above operation, and rinse the pipeline 3 ti...

Embodiment 2

[0067] A method for measuring fluorine content in niobium liquid, comprising the following steps:

[0068] Lanthanum nitrate solution preparation steps: Weigh 50.00g of lanthanum nitrate in a 500ml volumetric flask, dilute to 500ml with pure water, after the dissolution is complete, obtain a lanthanum nitrate solution, move the lanthanum nitrate solution to a potentiometric titration bottle, and wait for calibration;

[0069] Cleaning of the potentiometric titrator and selection of parameters: clean the pipeline of the potentiometric titrator with pure water, and operate the potentiometric titrator: power on—cleaning—confirmation, generally cleaning 3 times. After cleaning, ensure that there are no obvious air bubbles in the pipeline, such as If there are bubbles, repeat the last operation until there are no obvious bubbles in the pipeline, then use the pipeline of the lanthanum nitrate solution potentiometric titrator to repeat the above operation, and rinse the pipeline 3 tim...

Embodiment 3

[0078] A method for measuring fluorine content in tantalum neutralization mother liquor, comprising the following steps:

[0079] Lanthanum nitrate solution preparation steps: Weigh 20.00g of lanthanum nitrate in a 500ml volumetric flask, dilute to 500ml with pure water, after the dissolution is complete, obtain a lanthanum nitrate solution, move the lanthanum nitrate solution to a potentiometric titration bottle, and wait for calibration;

[0080] Cleaning of the potentiometric titrator and selection of parameters: clean the pipeline of the potentiometric titrator with pure water, and operate the potentiometric titrator: power on—cleaning—confirmation, generally cleaning 3 times. After cleaning, ensure that there are no obvious air bubbles in the pipeline, such as If there are bubbles, repeat the last operation until there are no obvious bubbles in the pipeline, then use the pipeline of the lanthanum nitrate solution potentiometric titrator to repeat the above operation, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com