Method for detecting nitrogen content in steelmaking auxiliary materials

A technology of nitrogen content and determination method, applied in the direction of chemical method analysis, measuring devices, analysis materials, etc., can solve the problems of no unified detection standard method, reduce the use of toxic and harmful chemical reagents, improve detection efficiency, and shorten the detection cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Example 1: A method for measuring nitrogen content in steelmaking auxiliary materials

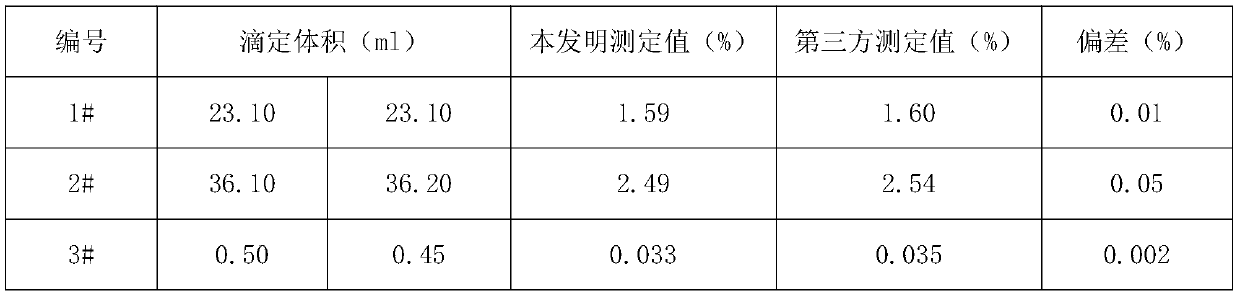

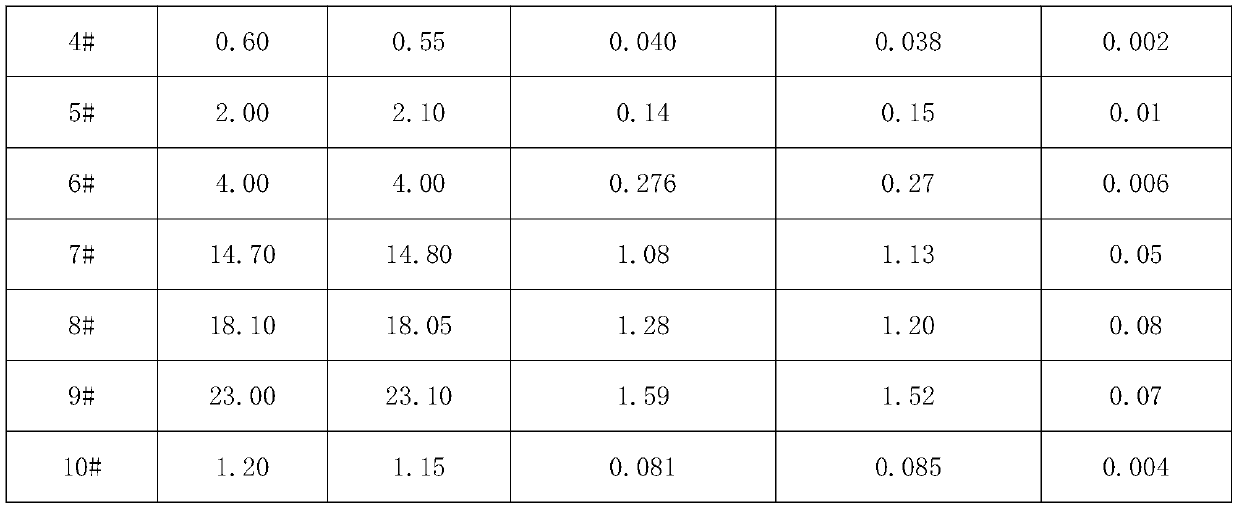

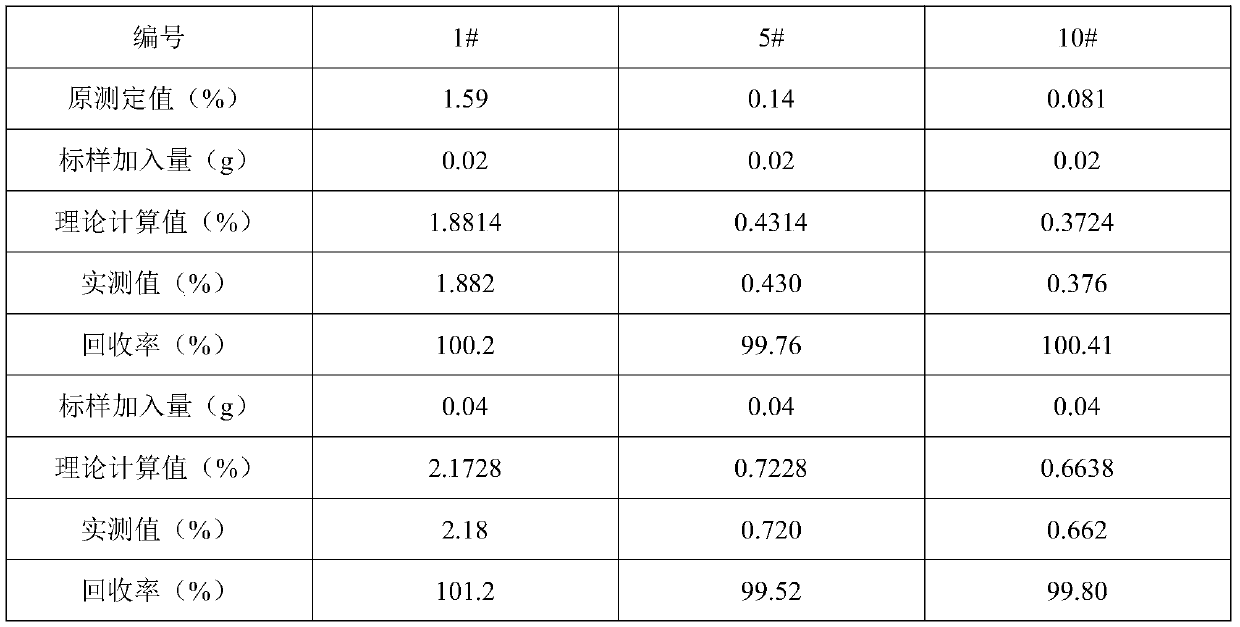

[0082] Weigh 1g of the auxiliary material sample into the Erlenmeyer flask, add 10mL phosphoric acid, heat to dissolve at 75℃, add 20mL concentrated sulfuric acid (the volume ratio of concentrated sulfuric acid to distilled water is 1:1), continue to boil, add 0.2g Sodium fluoride, heated until concentrated sulfuric acid smokes for 5 minutes, remove, cool, add 50mL distilled water, shake well, then boil to dissolve the salts, remove and cool to room temperature, add 30mL boric acid solution and 4 in a 300mL conical flask Drop the methyl red-methine blue indicator and place it at the lower end of the condenser. Pour the dissolved test solution from the funnel into the distillation flask, and then slowly add 80 mL of sodium hydroxide solution into the distillation flask through the funnel. Power on heating, control the distillation speed to 6-8mL / min, and finish when the distillate reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com