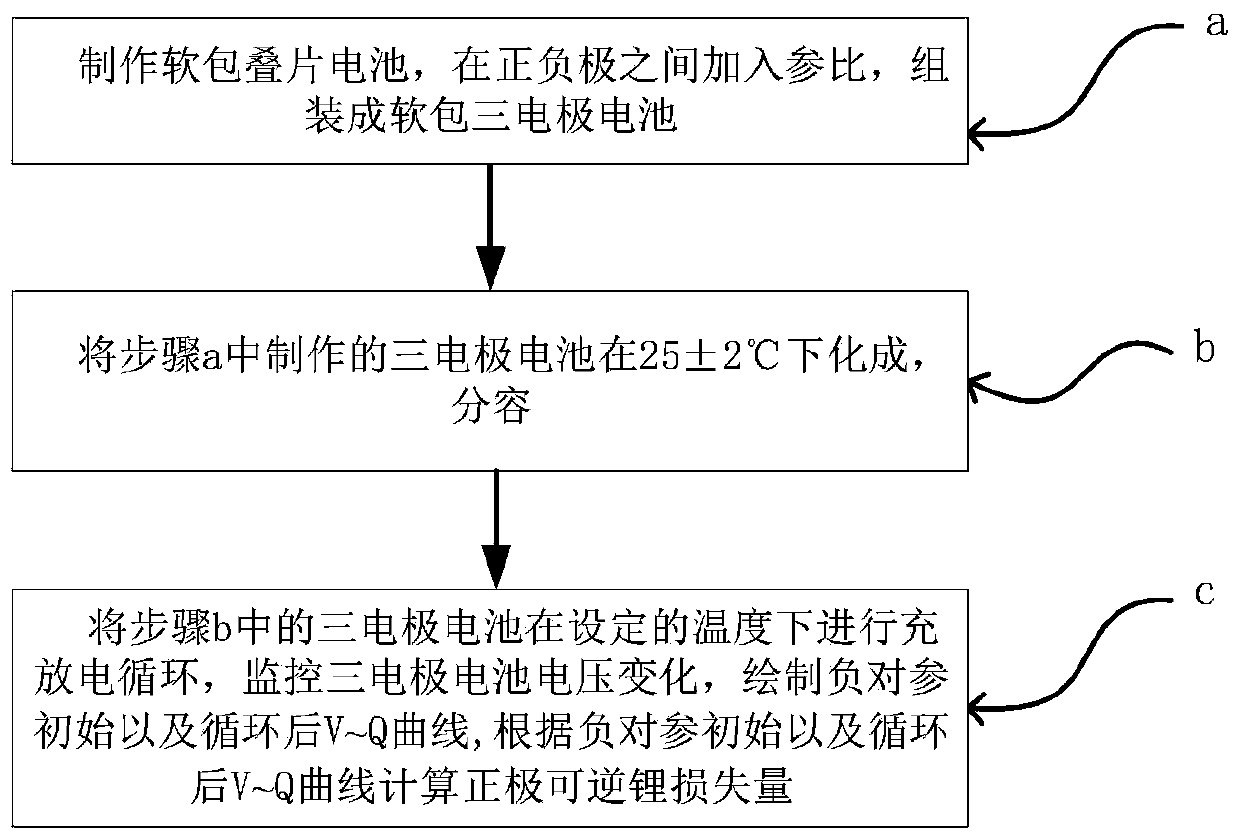

Non-destructive detection lithium ion battery anode reversible lithium loss method

A lithium-ion battery, non-destructive testing technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of risk, time-consuming, difficult operation, etc., to quantify the reversible lithium loss of the positive electrode, reduce risk, and be good The effect of practicality and feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

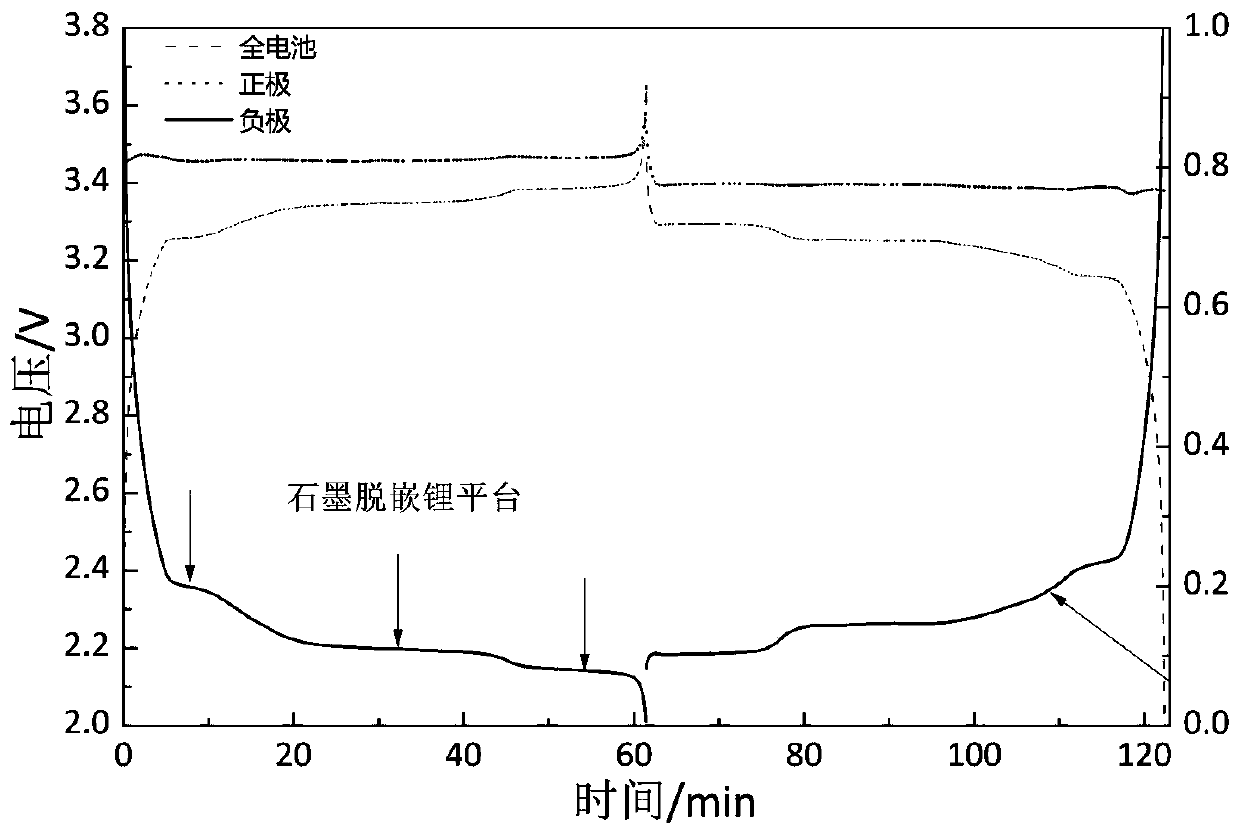

[0029] In this embodiment, a soft pack cell with a capacity of 5.6Ah is used, and the system is an LFP / C system. The system specifies a lower limit voltage of 2.0V and a specified upper limit voltage of 3.65V.

[0030] a. Make a soft-pack laminated battery, wherein there are 13 positive poles and 14 negative poles. A reference with a diameter of 25 μm is added between the positive and negative poles. The reference and the positive and negative poles are separated by a diaphragm, and then Liquid injection package.

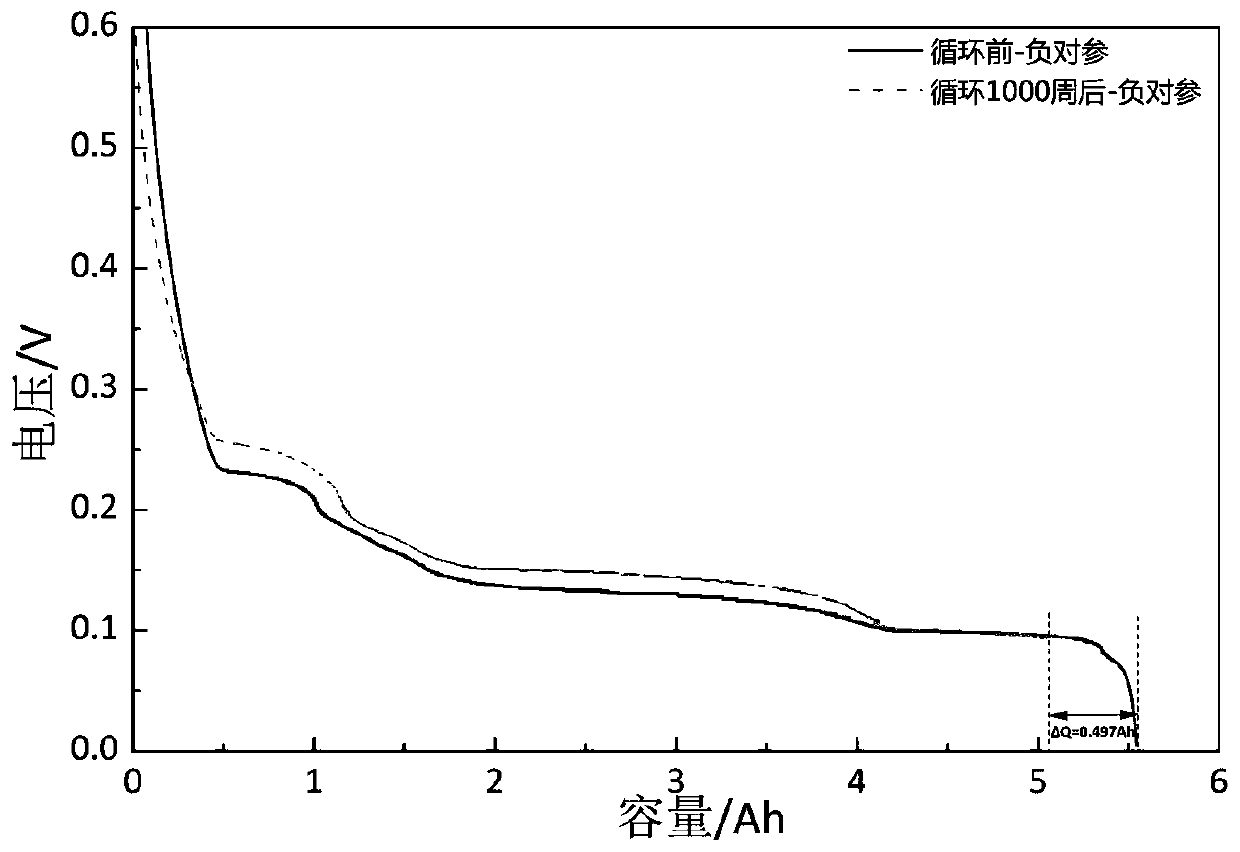

[0031] b. Form the three-electrode battery produced in step a at 25°C. The formation process is 0.02C constant current charge for 4 hours, rest for 10 minutes, and 0.1C constant current charge for 2 hours. Then the three-electrode battery was divided at 25°C. The capacity division process was 0.1C constant current and constant voltage charge to 3.65V, cut-off current was 0.05C, shelved for 30min, 0.33C discharged to 2.0V, shelved for 30min, and then 0.33C constant ...

Embodiment 2

[0034] Change the number of cycles to 2000, and other experimental conditions are the same as in Example 1. The negative-to-parameter charging curve for 2000 cycles is shown in 4, and the reversible lithium loss of the positive electrode is 1.296Ah. The results are shown in Table 1.

[0035]

[0036]

[0037] Table 1 shows the reversible lithium loss of the positive electrode for different cycles of 1C cycle at 25°C

Embodiment 3

[0039] In this embodiment, a soft pack cell with a capacity of 5.6Ah is used, and the system is an LFP / C system. The system specifies a lower limit voltage of 2.0V and a specified upper limit voltage of 3.65V.

[0040] a. Make a soft-pack laminated battery, wherein there are 13 positive poles and 14 negative poles. A reference with a diameter of 25 μm is added between the positive and negative poles. The reference and the positive and negative poles are separated by a diaphragm, and then Liquid injection package.

[0041] b. Form the three-electrode battery produced in step a at 25°C. The formation process is 0.02C constant current charge for 4 hours, rest for 10 minutes, and 0.1C constant current charge for 2 hours. Then the three-electrode battery was divided at 25°C. The capacity division process was 0.1C constant current and constant voltage charge to 3.65V, cut-off current was 0.05C, shelved for 30min, 0.33C discharged to 2.0V, shelved for 30min, and then 0.33C constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com