Use of surface-reacted calcium carbonate for preparing supersaturated aqueous systems

A surface-reactive, water-based system technology, applied in the direction of applications, botany equipment and methods, medical preparations containing active ingredients, etc., can solve poor usability, active ingredients or corresponding formulation efficacy active ingredient bioavailability limitations, low Solubility etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0240] Embodiment 1: preparation through surface reaction calcium carbonate

[0241]In a mixing vessel, 330 liters of an aqueous suspension of calcium carbonate-containing minerals were prepared by adjusting the solids content of ground limestone calcium carbonate from Omya SAS, Orgon having a median particle size on a weight basis of 1.3 μm as determined by sedimentation , such that a solids content of 10% by weight, based on the total weight of the aqueous suspension, is obtained.

[0242] While mixing the suspension at a mixer tip speed of 12.7 m / s, 10.6 kg of an aqueous solution containing 30% by weight of phosphoric acid, based on the total weight of the aqueous solution, were added to the suspension over a period of 12 minutes at a temperature of 70°C middle. After acid addition, the slurry was stirred for an additional 5 minutes before it was removed from the container and dried. During acid treatment, carbon dioxide is formed in situ in the aqueous suspension.

[...

Embodiment 2

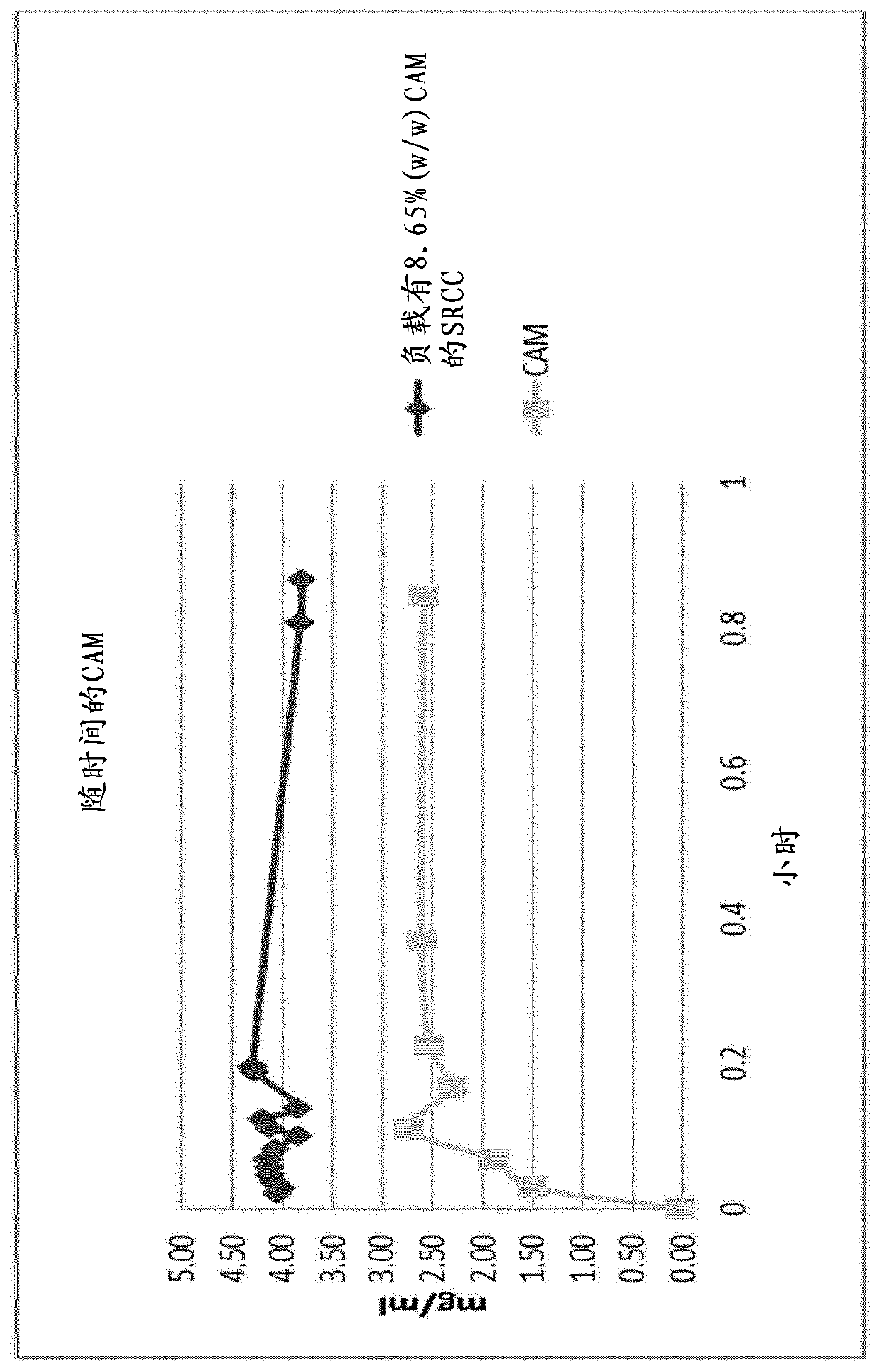

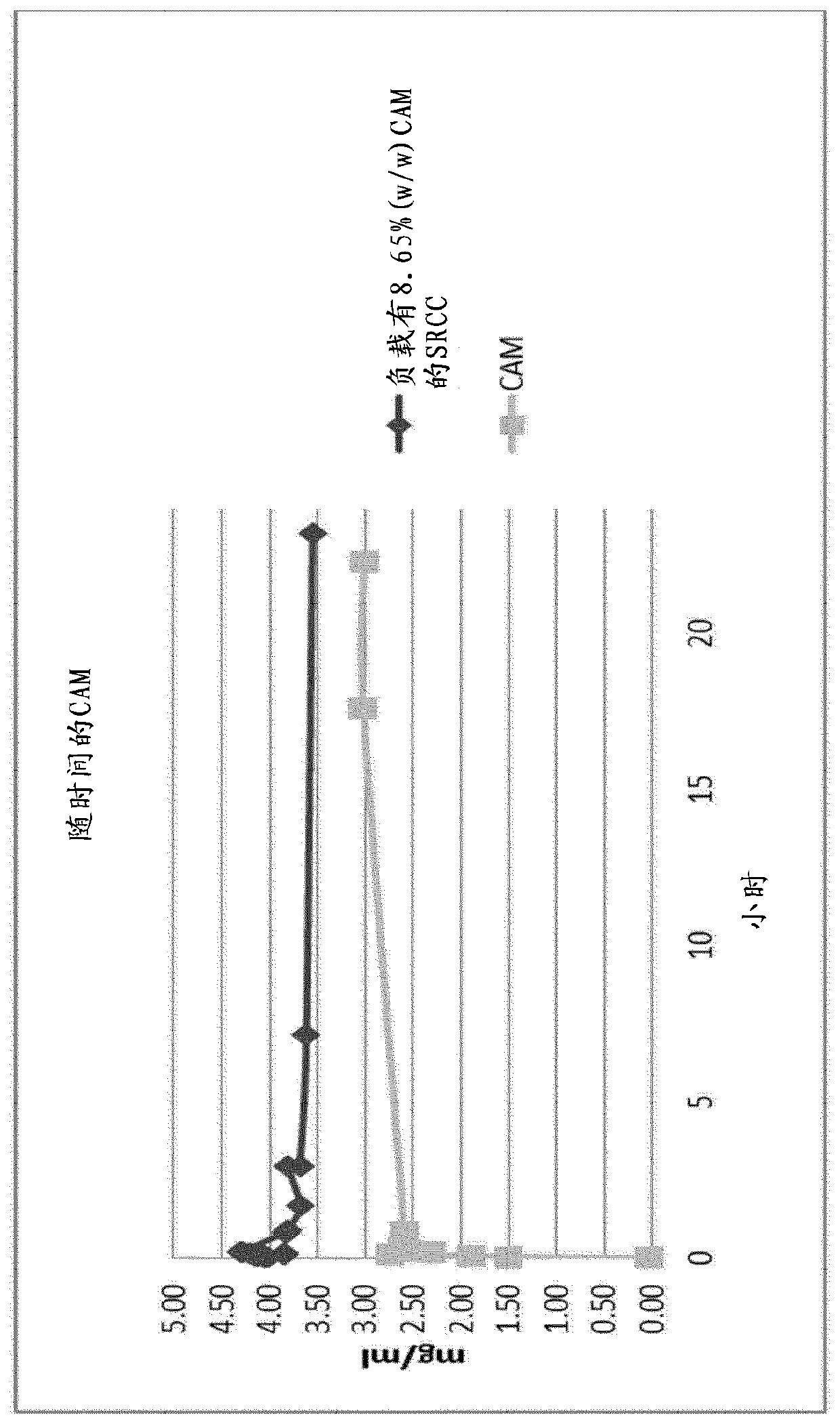

[0244] Embodiment 2: the supersaturated solution of chloramphenicol

[0245] load:

[0246] 100 g of the surface-reacted calcium carbonate (d 50 (Volume) ≈7μm, d 98 (volume)≈16μm, SSA≈55m 2 / g) Shake at 300 rpm using a Heidolph Uni 2010 orbital shaker in a 11 Il Ischia flask. A 133 g / ml stock solution of chloramphenicol (dried, purchased from Merck, #1.02366.0050) in absolute ethanol was added dropwise at a rate of 1.5 drops / sec using a buret until the SRCC powder was loaded with 8.65% w / w of chloramphenicol. The samples were dried at room temperature. The percent loading and absence of ethanol was confirmed by TGA.

[0247] Calibration curve:

[0248] The following standard solutions of chloramphenicol in water were prepared and analyzed by UV-VIS: 0.013 mg / ml, 0.083 mg / ml, 0.113 mg / ml, 0.167 mg / ml and 0.333 mg / ml. The absorbance of each 3 μl standard was measured at 280nm in a Nanodrop 2000c device and used as a reference to determine a calibration curve of "mg / ml ...

Embodiment 3

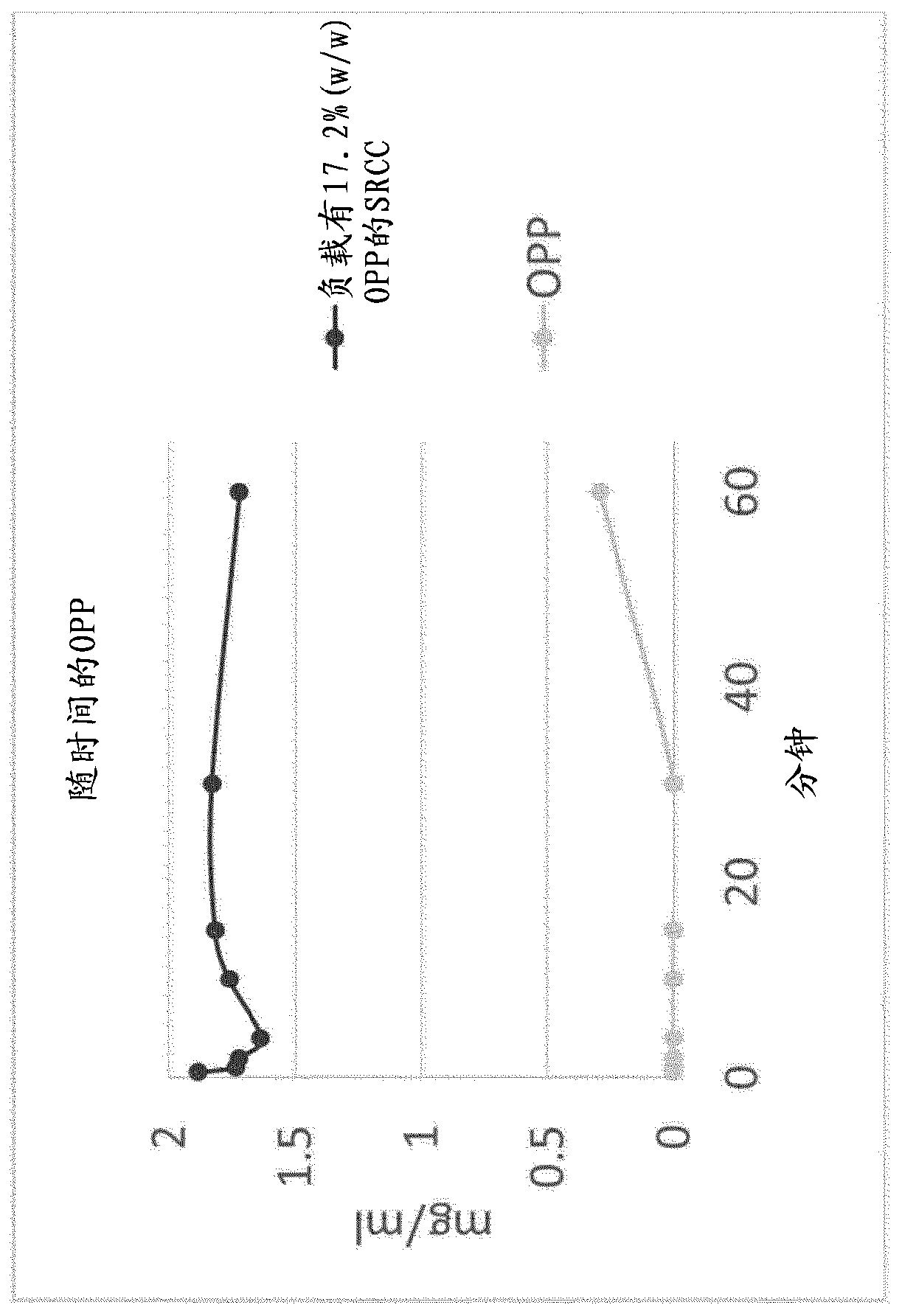

[0255] Example 3: Supersaturated solution of 2-phenylphenol

[0256] load:

[0257] 50 g of surface-reacted calcium carbonate (d 50 (Volume) ≈7μm, d 98 (volume)≈16μm, SSA≈55m 2 / g) Shake at 300 rpm using a Heidolph Uni 2010 orbital shaker in a 11 Il Ischia flask. Using a burette, a stock solution of 75% w / w 2-phenylphenol (purchased from Lanxess, Preventol O Extra) in absolute ethanol was added dropwise at a rate of 1.5 drops / s until the SRCC powder was loaded with 17.2% w / w 2-Phenylphenol of w. The samples were dried at room temperature. The percent loading and absence of ethanol was confirmed by TGA.

[0258] Calibration curve:

[0259] Prepare the following standard solutions of 2-phenylphenol in water and analyze by UV-VIS: 0.025mg / ml, 0.05mg / ml, 0.1mg / ml, 0.2mg / ml, 0.4mg / ml, 0.6mg / ml and 0.8mg / ml. The absorbance of each 3 μl standard was measured at 283 nm in a Nanodrop 2000c device and used as a reference to determine a calibration curve of "mg / ml 2-phenylphenol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Volume median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com