H13 die steel and heat treatment technique thereof

A technology of die steel and heat treatment furnace, applied in the field of H13 die steel and its heat treatment process, can solve the problems of unstable mechanical properties of H13 die steel, and achieve the effects of improving purity and density, promoting full diffusion and reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

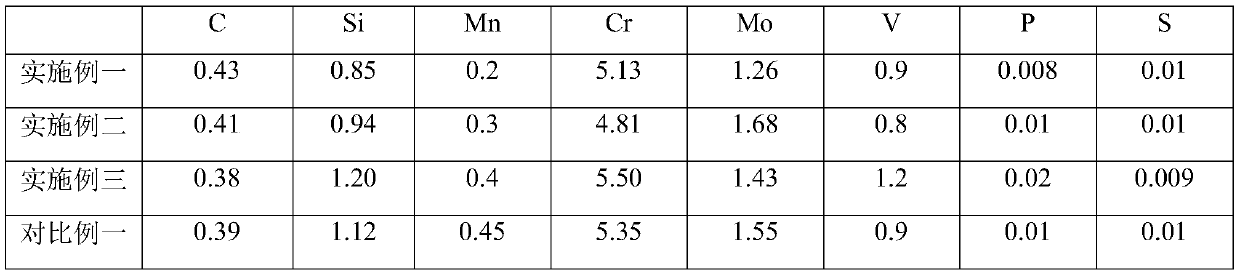

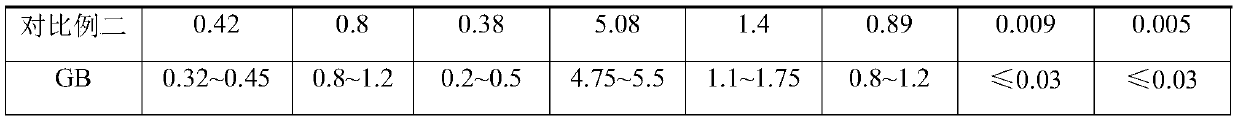

Embodiment 1

[0016] A heat treatment process for H13 die steel, comprising the following steps:

[0017] (1) Primary heat treatment: Air-cool the forged H13 billet (1120mm×690mm×170mm) to 450°C in air, then put it into a heat treatment furnace with a furnace temperature of 300°C, and increase the furnace temperature at a heating rate of 15°C / h Raise to 550°C, hold for 3 hours, then raise the furnace temperature to 850°C at a heating rate of 25°C / h, hold for 2 hours, then quickly raise the furnace temperature to 1000°C, hold for 10 hours, and then quickly cool the H13 billet The temperature drops to 350°C;

[0018] (2) Secondary heat treatment: put the H13 billet processed in step (1) into a heat treatment furnace with a furnace temperature of 300°C, raise the furnace temperature to 630°C at a heating rate of 10°C / h and keep it warm for a holding time of 100s / mm (for every 1mm increase in steel thickness, the holding time is extended by 100s); then the furnace temperature is raised to 900°...

Embodiment 2

[0022] A heat treatment process for H13 die steel, comprising the following steps:

[0023] (1) Primary heat treatment: Air-cool the forged H13 billet (1120mm×690mm×170mm) to 480°C in air, then put it into a heat treatment furnace with a furnace temperature of 280°C, and increase the furnace temperature at a heating rate of 10°C / h. Raise to 560°C, hold for 2.5 hours, then raise the furnace temperature to 870°C at a heating rate of 40°C / h, hold for 2 hours, then quickly raise the furnace temperature to 1050°C, hold for 10 hours, and then cool the H13 The temperature of the billet drops to 370°C;

[0024] (2) Secondary heat treatment: put the H13 billet processed in step (1) into a heat treatment furnace with a furnace temperature of 280°C, raise the furnace temperature to 640°C at a heating rate of 15°C / h and keep it warm for a holding time of 90s / mm; then raise the furnace temperature to 930°C at a heating rate of 15°C / h and keep it warm for 130s / mm; then raise the furnace te...

Embodiment 3

[0028] A heat treatment process for H13 die steel, comprising the following steps:

[0029] (1) Primary heat treatment: Air-cool the forged H13 billet (1120mm×690mm×170mm) to 500°C in air, then put it into a heat treatment furnace with a furnace temperature of 250°C, and increase the furnace temperature at a heating rate of 20°C / h. Raise to 570°C, hold for 2 hours, then raise the furnace temperature to 900°C at a heating rate of 50°C / h, hold for 1 hour, then quickly raise the furnace temperature to 1050°C, hold for 8 hours, and then quickly cool the H13 billet The temperature drops to 400°C;

[0030] (2) Secondary heat treatment: put the H13 billet processed in step (1) into a heat treatment furnace with a furnace temperature of 250°C, raise the furnace temperature to 650°C at a heating rate of 20°C / h and keep it warm for a holding time of 80s / mm; then raise the furnace temperature to 950°C at a heating rate of 20°C / h and keep it warm for 120s / mm; then raise the furnace tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com