A process method for producing mandrel by direct forging of continuous casting billet

A process method and technology of continuous casting slabs, which are applied in the field of seamless pipe rolling tools, can solve problems such as continuous porosity, shrinkage cavities and other defects that cannot be eliminated, and achieve elimination of carbides and segregation phenomena, uniform quality, and crystallization speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

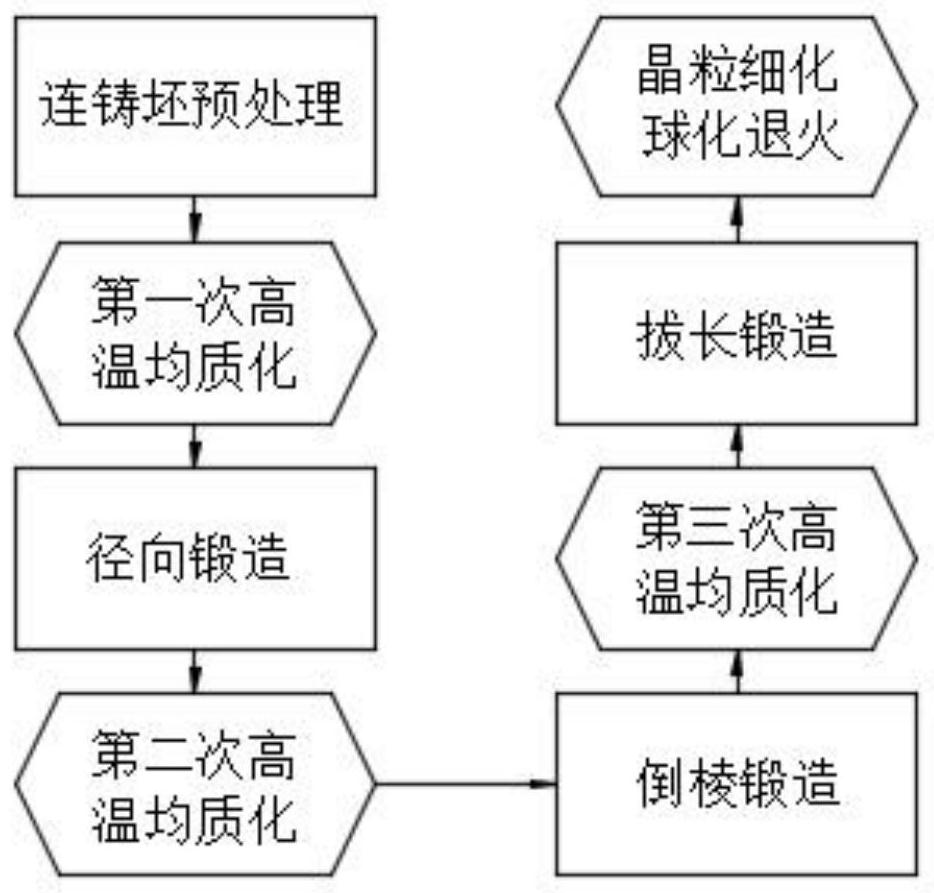

Method used

Image

Examples

Embodiment 1

[0053] A process method for producing mandrels by direct forging of continuous casting billets: using continuous casting billets with a diameter of 500 mm to produce a finished mandrel bar with a diameter of 182.7 mm and a length of 11.5 meters, and the weight is 2365 kilograms. Feeding 2650 kg, total material rate: 89%.

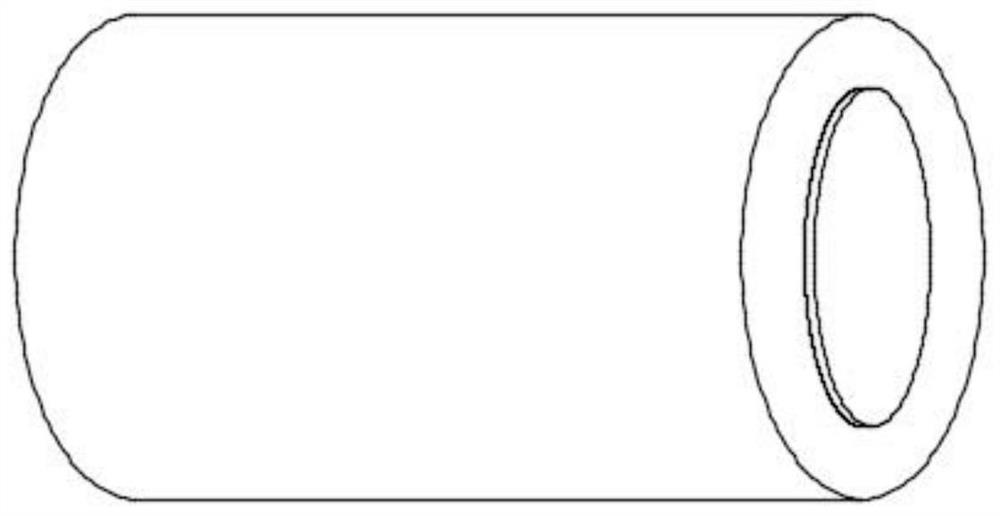

[0054] Step A: The annealed continuous casting billet is φ500 mm (steel type is H13 (4Cr5MoSiV1)), sawed and cut to a length of 1725 mm, and a circular A3 carbon plate with a thickness of 3 mm and a diameter of 375 mm is used for circumferential sealing and welding. The thickness of the surfacing layer is 3 mm. After the sealing and welding is completed, the stress relief treatment is carried out: the temperature is raised to 600 °C at 40 °C / hour, and the core is kept warm for 2 hours; the continuous casting billet after the sealing and welding stress relief treatment is placed in the heating furnace. It is heated to 1280°C inside, and the center reaches the...

Embodiment 2

[0062] A process method for producing mandrels by direct forging of continuous casting billets: using continuous casting billets with a diameter of 390 mm to produce a finished mandrel rod with a diameter of 182.7 mm and a length of 11.5 meters, and the weight is 2365 kilograms. Feeding 2650 kg, total material rate: 89%.

[0063] Step A: The annealed continuous casting billet is φ390 mm (steel type is H13 (4Cr5MoSiV1)), sawed and cut to a length of 2832 mm, and a circular A3 carbon plate with a thickness of 4 mm and a diameter of 293 mm is used for circumferential sealing and welding. The thickness of the surfacing layer is 4 mm, and the stress relief treatment is carried out after the sealing welding is completed: the temperature is raised to 600 °C at 60 °C / hour, and the core is kept warm for 2 hours; the continuous casting billet after the sealing welding stress relief treatment is placed in the heating furnace. It is heated to 1290°C inside, and the center reaches the set ...

Embodiment 3

[0071] A process method for producing mandrels by direct forging of continuous casting billets: using continuous casting billets with a diameter of 500 mm to produce a finished mandrel bar with a diameter of 272.6 mm and a length of 11.5 meters, and the weight is 5266 kilograms. Feeding 5908 kg, total material rate: 89%.

[0072] Step A: The annealed continuous casting billet is φ500 mm (steel type is H13 (4Cr5MoSiV1)), sawed and cut to a length of 3836 mm, and a circular A3 carbon plate with a thickness of 5 mm and a diameter of 375 mm is used, and the circumference is sealed and welded. The thickness of the surfacing layer is 5 mm, and the stress relief treatment is carried out after the sealing and welding is completed: the temperature is raised to 600 °C at 80 °C / hour, and the core is kept warm for 2 hours; the continuous casting billet after the sealing and welding stress relief treatment is placed in the heating furnace It is heated to 1300°C inside, and the center reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com