ZnSe/ZnO based nitrogen dioxide gas sensor and preparation processthereof

A gas sensor and nitrogen dioxide technology, applied in the direction of material resistance, etc., can solve the problems of cumbersome preparation process, etc., and achieve the effect of simple process flow, improved gas-sensing performance, and good gas-sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

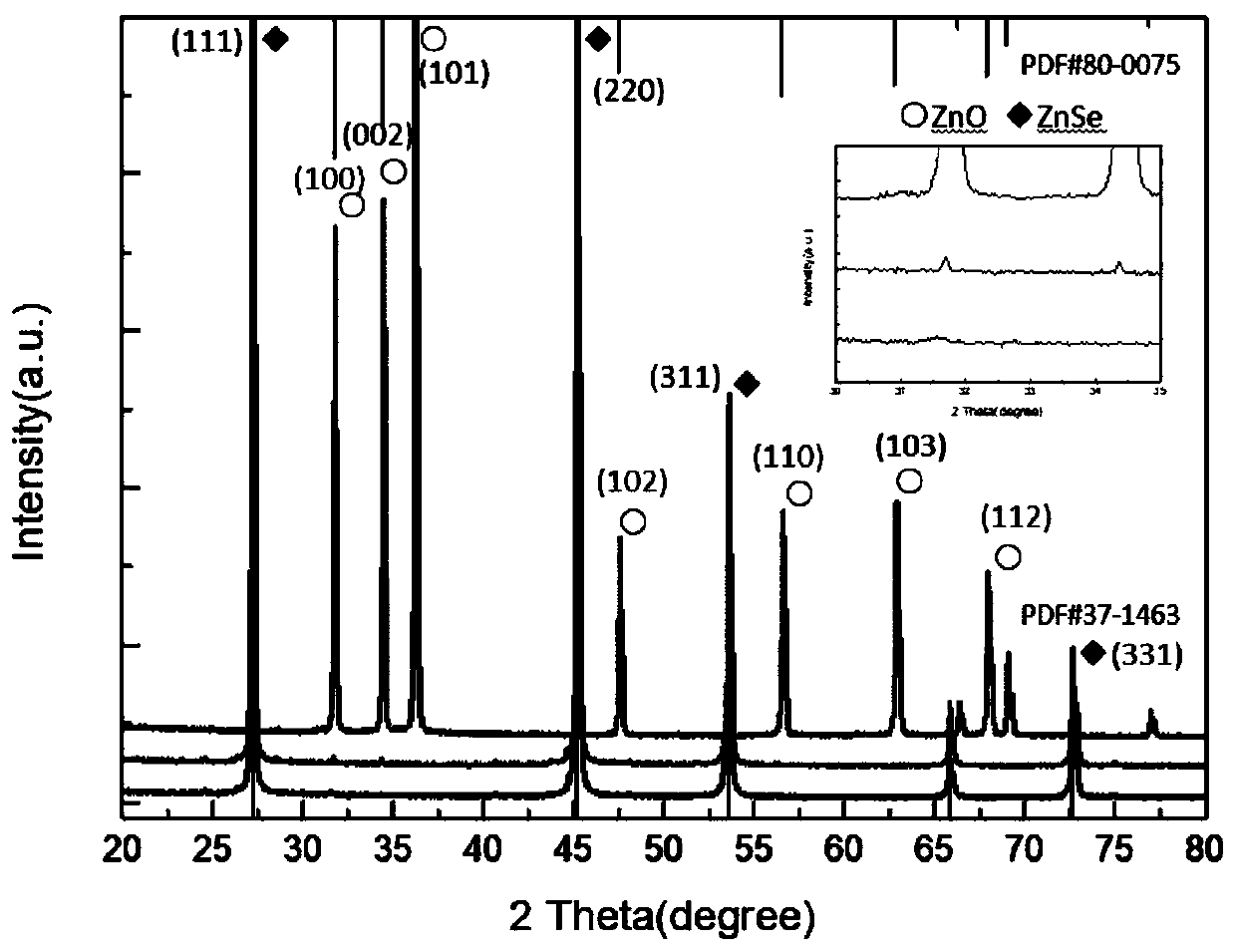

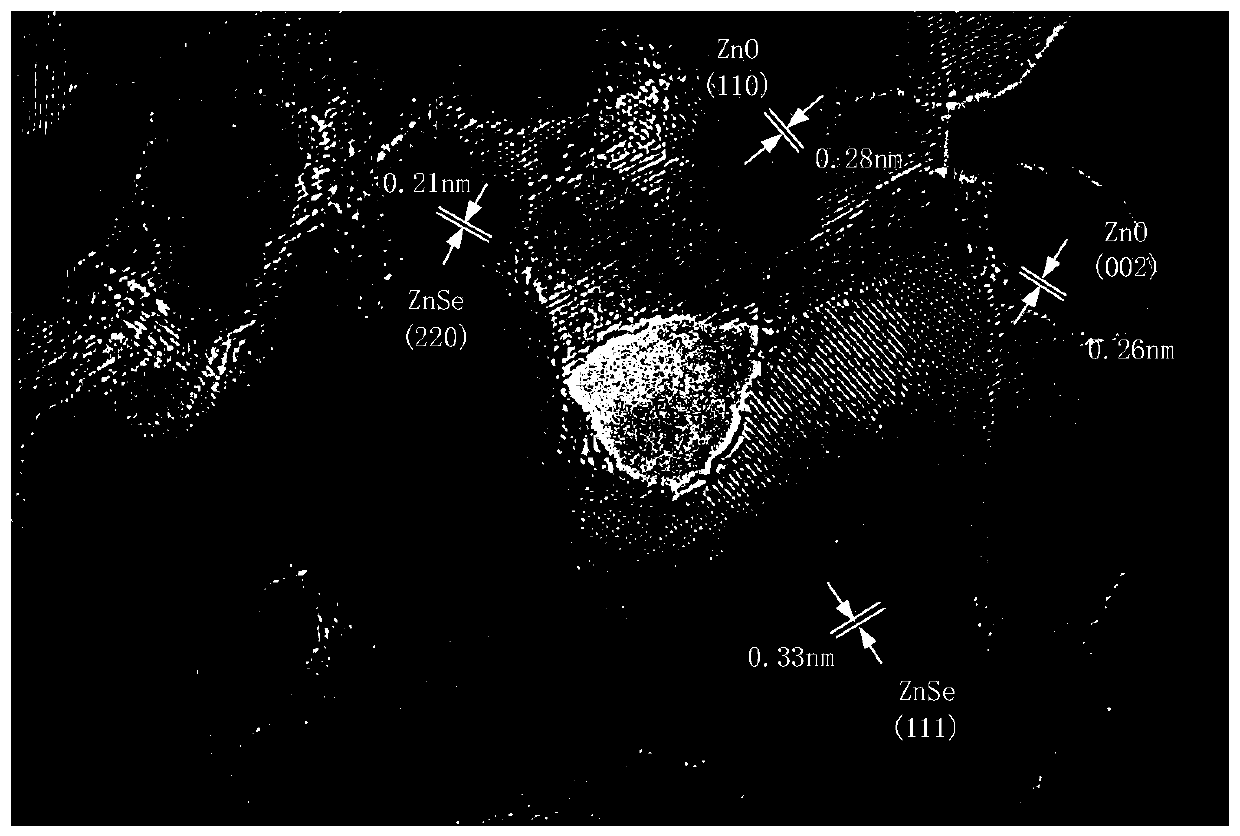

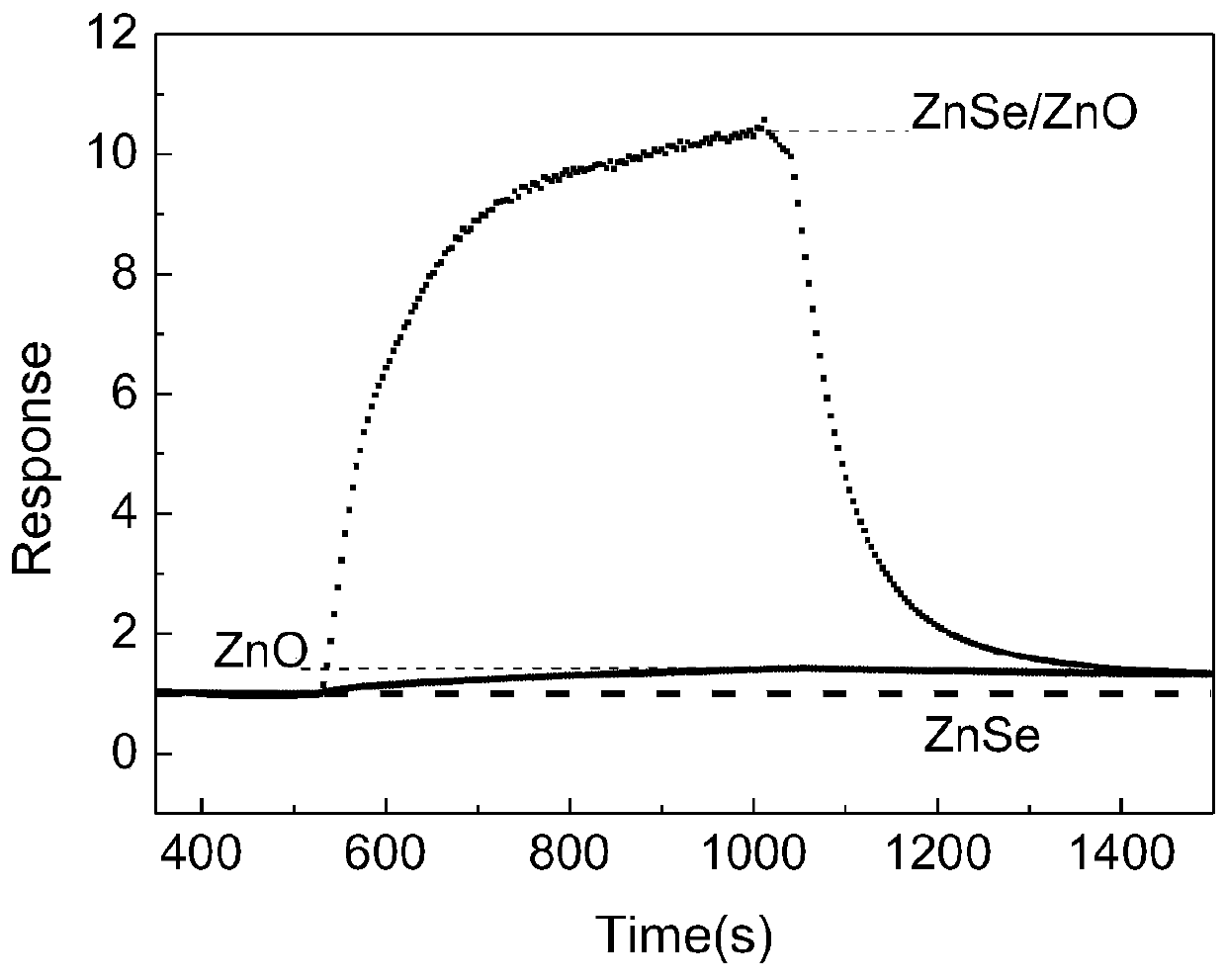

[0028] The nitrogen dioxide gas sensor based on ZnSe / ZnO is composed of a gas sensitive material and a heating electrode, and the gas sensitive material is uniformly coated on the surface of the heating electrode, and the coating thickness is 80 μm. The gas-sensitive material component is a heterojunction composite nanomaterial formed by zinc selenide and zinc oxide prepared by an in-situ oxidation method, and the size of the material is 400nm. The preparation method comprises the following steps:

[0029] Step 1, preparation of ZnSe / ZnO heterojunction: Zinc selenide powder is placed in the ark and put into a tube furnace, and a dry mixed gas of 20% oxygen (50sccm) and 80% nitrogen (200sccm) is introduced at the same time, with 3 Heating at a speed of ~5°C / min, the reaction temperature is 400°C, the reaction time is 2h, and then naturally cooled to room temperature to obtain a ZnSe / ZnO heterojunction.

[0030] Step 2, preparing the gas sensor: put a small amount of ZnSe / ZnO h...

Embodiment 2

[0036] The nitrogen dioxide gas sensor based on ZnSe / ZnO is composed of a gas sensitive material and a heating electrode, and the gas sensitive material is uniformly coated on the surface of the heating electrode, and the coating thickness is 50 μm. The gas-sensitive material component is a heterojunction composite nanomaterial formed by zinc selenide and zinc oxide prepared by an in-situ oxidation method, and the size of the material is 200nm. The preparation method comprises the following steps:

[0037] Step 1, preparation of ZnSe / ZnO heterojunction: Zinc selenide powder is placed in the ark and put into a tube furnace, and a dry mixed gas of 20% oxygen (50sccm) and 80% nitrogen (200sccm) is introduced at the same time, with 3 Heating at a speed of ~5°C / min, the reaction temperature is 600°C, the reaction time is 0.5h, and then naturally cooled to room temperature to obtain a ZnSe / ZnO heterojunction.

[0038] Step 2, preparing the gas sensor: put a small amount of ZnSe / ZnO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com