Coating method of beam-splitting grin-lens and Glens

A technology of self-focusing and spectroscopic film, applied in the direction of lens, optics, optical components, etc., to achieve the effect of reducing the amount of glue used, high stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of spectroscopic self-focusing Glens lens coating method comprises the following methods:

[0032] 1) Determine the film structure:

[0033] According to the refractive index distribution and technical requirements of the Glens lens, determine the high refractive index material H and the low refractive index material L, and then determine the preliminary film structure;

[0034] Technical requirements:

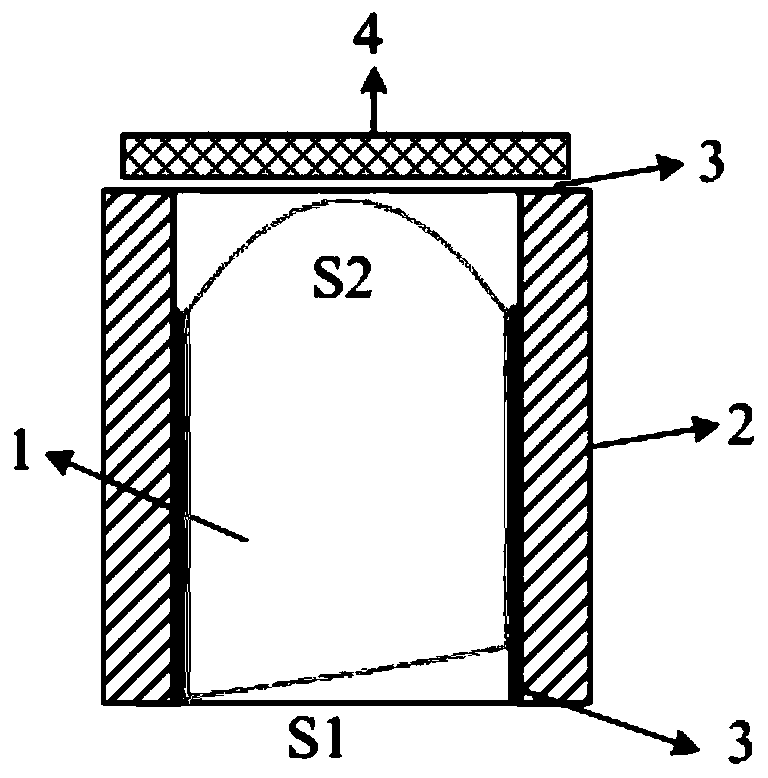

[0035] Spectral coating on S2 surface

[0036] Working wavelength: 1260nm-1620nm

[0037] Transmittance

[0038] Transmission WDL: ≦0.25dB@1260nm-1380nm

[0039] ≦0.2dB@1500-1620nm

[0040] Reflection WDL: ≦0.05dB

[0041] Withstand optical power: the lens is required to withstand at least 1000mV optical power emitted from the fiber

[0042] Working temperature range -40℃~+85℃

[0043] Storage temperature -40℃~150℃

[0044] Working humidity: 0~90%RH

[0045] The central wavelength of the Glens lens is 1420nm, and the high refractive index ...

Embodiment 2

[0050] Embodiment 2: The coating process is IAD ion beam assisted deposition. Since the self-focusing Glens lens belongs to the formula glass material, the structure is special, and the environmental stability is not good. A bonding layer with good stability is added between the system structures, on the one hand to protect the lens, and on the other hand to ensure its bonding force with the lens and film structure.

Embodiment 3

[0051] Embodiment 3: A spectroscopic self-focusing Glens lens, comprising a lens body, and a spectroscopic film is coated on the light-emitting surface of the lens body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com