Surface treated lithium-ion battery positive electrode active material substance and preparation method and application thereof

A lithium-ion battery and cathode active technology, which is applied in the direction of electrode manufacturing, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve problems such as complex processes, affecting the electronic conductivity of active material particles, and difficulty in ensuring coating uniformity. Effects of reduced deterioration, wide application, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Preparation of lithium ion battery electrode slurry:

[0054] The preparation of the electrode slurry of the present invention is prepared according to a conventional method, wherein the mass ratio of each component is: the compound of the positive electrode active material and carbon material through the surface treatment of lithium ion battery: polyvinylidene fluoride: conductive carbon black=100: 5:1.5. The solvent used in the electrode slurry is NMP.

[0055] Lithium-ion battery performance test:

[0056] The lithium-ion battery assembled with the electrode paste prepared by the above method was tested for charge and discharge performance at 1C rate. Evaluation of the degree of deterioration of the positive electrode active material after the charge and discharge test:

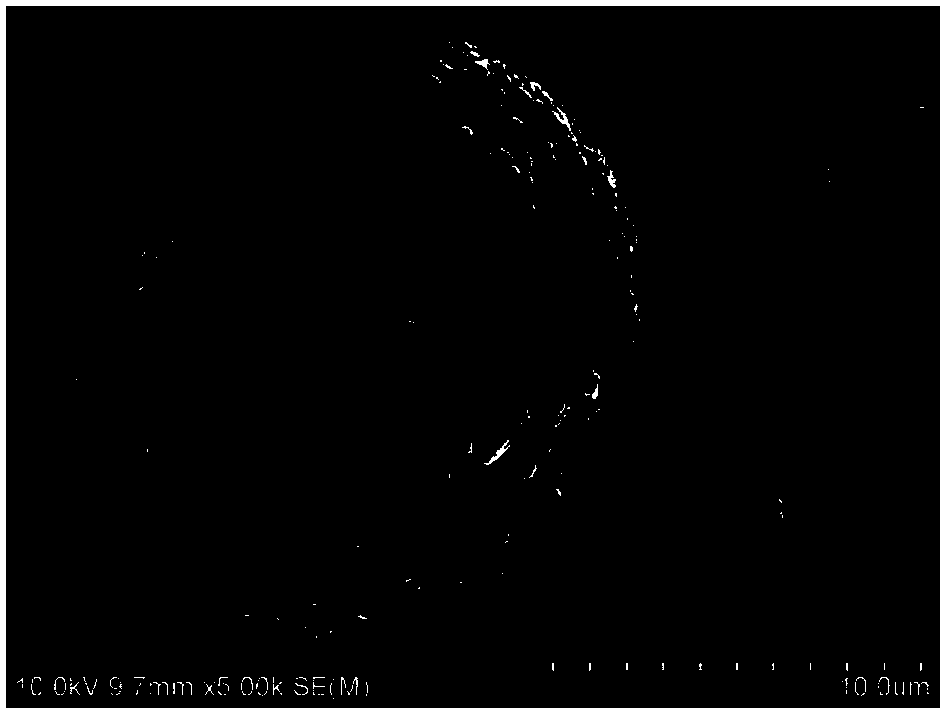

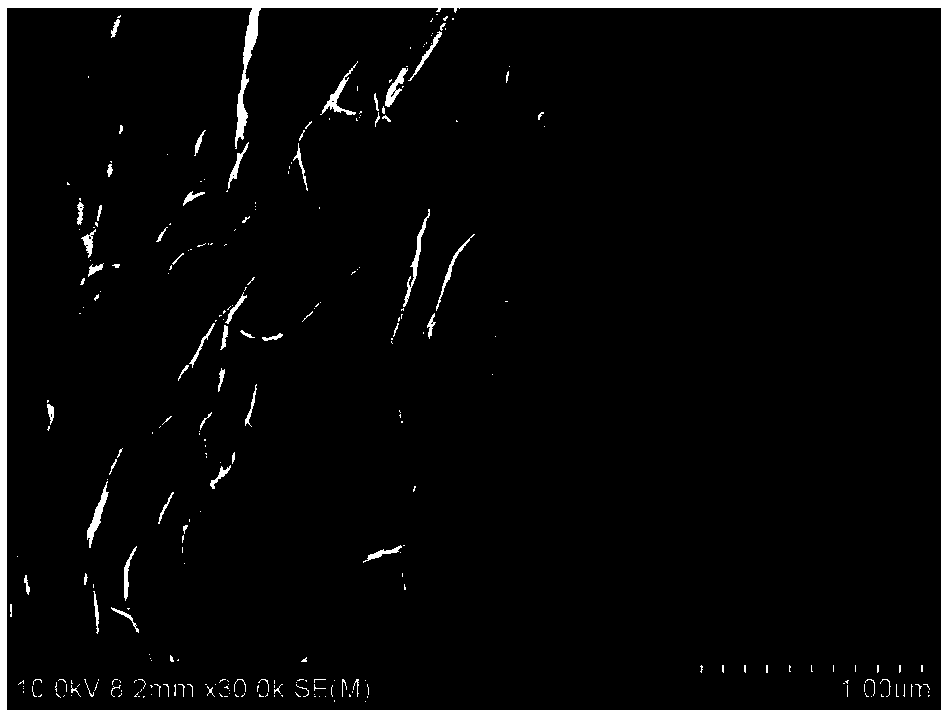

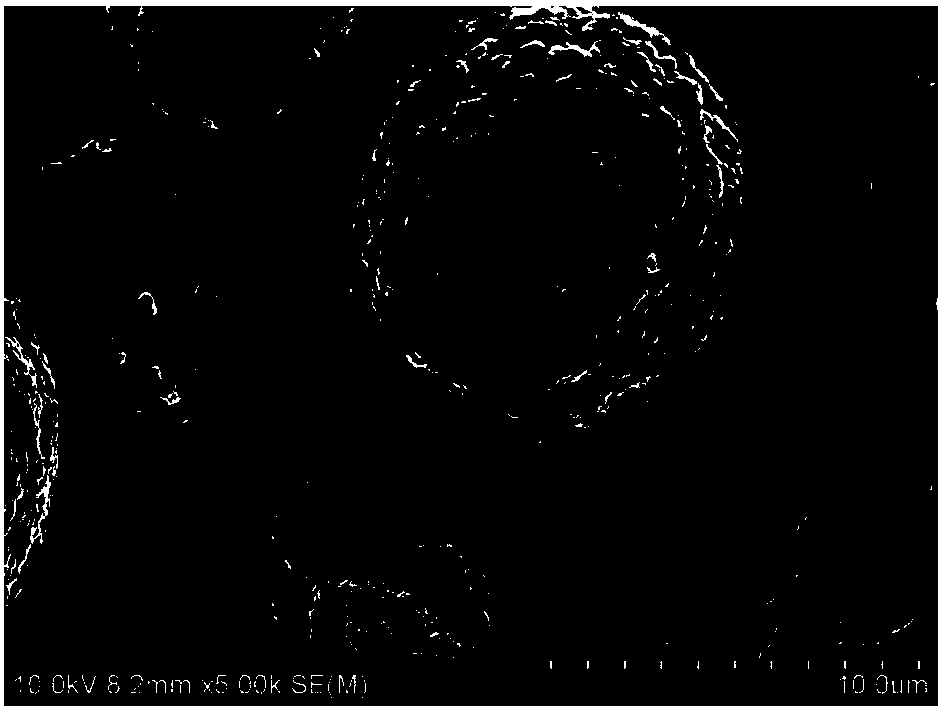

[0057] After the lithium ion battery assembled with the electrode paste prepared by the above method was subjected to battery charge and discharge test for 300 cycles, a scanning transmission ele...

Embodiment 1

[0059] Under room temperature conditions, the nickel-cobalt-manganese ternary material of the positive electrode active material and the compound diethylenetriamine having an amine structure are uniformly mixed in water, kept for 1 minute, and dried to obtain the surface-treated positive electrode active material of the lithium ion battery.

[0060] Wherein the mass ratio of the positive electrode active material to the compound having an amine structure is 100:0.1.

[0061] The surface-treated lithium ion battery cathode active material is mixed with carbon nanotubes and graphene oxide in a solution to obtain a compound after purification. The mass ratio of the surface-treated lithium-ion battery cathode active material to the carbon material is 100:0.1. The composite surface has a complete and uniform coating layer.

[0062] The lithium-ion battery using the composite has a retention rate of 97% after 100 cycles through charge and discharge tests.

Embodiment 2

[0064] Under room temperature conditions, the nickel-cobalt-manganese ternary material of the positive electrode active material and the compound triethylenetetramine having an amine structure are uniformly mixed in ethanol, kept for 1 minute, and dried to obtain a surface-treated lithium ion battery positive electrode active material.

[0065] Wherein the mass ratio of the positive electrode active material to the compound having an amine structure is 100:5.

[0066] The surface-treated lithium ion battery cathode active material is mixed with carbon nanotubes, graphene oxide and graphene in a solution to obtain a compound after purification. The mass ratio of the surface-treated lithium-ion battery cathode active material to the carbon material is 100:5. The composite surface has a complete and uniform coating layer.

[0067] The lithium-ion battery using the composite has been tested for charging and discharging, and the retention rate after 100 cycles can reach 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com