High-calcium gristle beef board and preparation process thereof

A technology of beef plate and beef, which is applied in the field of food processing, can solve the problems of inconvenient eating of pig bones, inconvenient eating, and difficult chewing by users, so as to prevent and treat cardiovascular and cerebrovascular diseases, prevent arteriosclerosis, and improve the body's immunity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

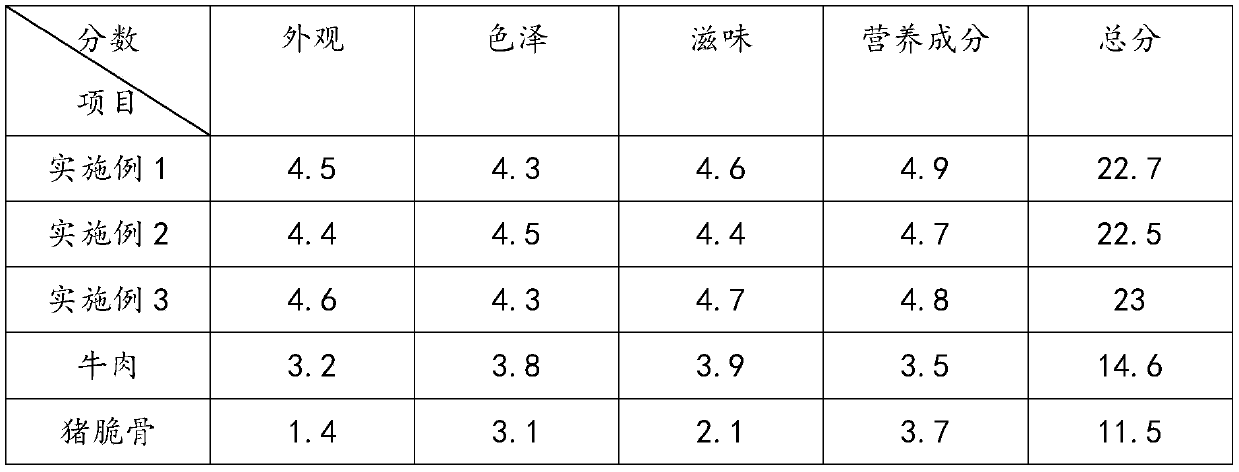

Embodiment 1

[0040] A high-calcium crispy beef plate, characterized in that the raw material formula is as follows: 76 parts by weight of beef, 26 parts by weight of pork crispy bones, 2.6 parts by weight of soybean protein, 2.6 parts by weight of edible salt, 1.6 parts by weight of white sugar, and 1.6 parts by weight of konjac powder , 0.02 parts by weight of food additives, 0.02 parts by weight of food flavors and fragrances, 0.016 parts by weight of compound emulsifier, and 10 parts by weight of water.

[0041] Specifically, the pork brittle bones are pork brittle bones with beef, wherein the ratio of beef to brittle bones is 1.5:8.5, and the particle size of the pork brittle bones is 0.45mm.

[0042] A kind of preparation method of high-calcium brittle beef plate, concrete steps are as follows:

[0043] (1) Beef slices: Take fresh or frozen raw beef that has passed the inspection, wash it directly or after thawing, trim the surface and internal fat, lymph, blood vessels, congestion, b...

Embodiment 2

[0057] A kind of high-calcium crispy beef plate, the raw material formula is as follows: 96 parts by weight of beef, 26 parts by weight of pork crispy bones, 3.6 parts by weight of soybean protein, 3.6 parts by weight of edible salt, 2.6 parts by weight of white granulated sugar, 2.6 parts by weight of konjac powder, and 0.05 parts by weight of food additives parts by weight, 0.05 parts by weight of edible essence and fragrance, 0.026 parts by weight of compound emulsifier, and 15 parts by weight of water.

[0058] Specifically, the pork brittle bones are pork brittle bones with beef, wherein the ratio of beef to brittle bones is 1.5:8.5, and the particle size of the pork brittle bones is 0.45 mm.

[0059] A kind of preparation method of high-calcium brittle beef plate, concrete steps are as follows:

[0060] (1) Beef slices: Take fresh or frozen raw beef that has passed the inspection, wash it directly or after thawing, trim the surface and internal fat, lymph, blood vessels,...

Embodiment 3

[0074] A kind of high-calcium crispy beef plate, the raw material formula is as follows: 80 weight parts of beef, 20 weight parts of pork crispy bones, 3 weight parts of soybean protein, 3 weight parts of edible salt, 2 weight parts of white granulated sugar, 2 weight parts of konjac powder, food additive 0.04 parts by weight, 0.04 parts by weight of food flavor and fragrance, 0.02 parts by weight of compound emulsifier, and 13 parts by weight of water.

[0075] Specifically, the pork brittle bones are pork brittle bones with pork, wherein the ratio of pork to brittle bones is 1.5:8.5, and the particle size of the pork brittle bones is 0.45mm.

[0076] A kind of preparation method of high-calcium brittle beef plate, concrete steps are as follows:

[0077] (1) Beef slices: Take fresh or frozen raw beef that has passed the inspection, wash it directly or after thawing, trim the surface and internal fat, lymph, blood vessels, congestion, broken bones and dirt, cut the beef into 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com