Straw biogas slurry fertilizer, and preparation method and application thereof

A technology of biogas slurry fertilizer and straw, which is applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of separate treatment, large drying amount of straw, and high water content of biogas slurry, so as to reduce the incidence of diseases and insect pests and improve soil physical properties. structure, enhance the effect of soil biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the production method of straw biogas slurry fertilizer

[0030] (1) Raw material and formula: corn stalk: 0.5 part; wheat straw: 0.5 part; biogas slurry 2 parts;

[0031] (2) Adding composite bacteria: adding composite bacteria according to the ratio of composite bacteria and mixed raw materials at a ratio of 0.5:100 by weight. The parts by weight of Bacillus subtilis, Bacillus jelly-like, and Trichoderma harzianum are respectively 0.02 part, 0.01 part, 0.01 part and 0.01 part in the composite bacteria;

[0032] (3) Stacking specifications: stack the straw biogas slurry mixture with adjusted water and added complex bacteria into a pile shape, with a height of 1 meter;

[0033] (4) Turn over and replenish biogas fluid: turn over every 3 days, and replenish biogas slurry in the later stage;

[0034] (5) Add wood vinegar: add 0.006 part of wood vinegar in the later stage of fermentation;

[0035] (6) Add carbonized organic matter: add 0.005 parts of carbo...

Embodiment 2

[0038] Embodiment 2: the production method of straw biogas slurry fertilizer

[0039] (1) Raw material and formula: corn stalk: 1 part; wheat straw: 1 part; biogas slurry 3 parts;

[0040] (2) Add composite bacteria: add composite bacteria according to the ratio of composite bacteria and mixed raw materials with a ratio of 1:100 by weight. The parts by weight of Bacillus subtilis, Bacillus jelly-like, and Trichoderma harzianum are respectively 0.04 part, 0.02 part, 0.02 part and 0.02 part in the composite bacteria;

[0041] (3) Stacking specifications: stack the straw biogas slurry mixture with adjusted water and added complex bacteria into a pile shape, with a height of 1 to 1.5 meters;

[0042] (4) Turn over and replenish biogas fluid: turn over every 3 days, and replenish biogas slurry in the later stage;

[0043] (5) Add wood vinegar: add 0.01 part of wood vinegar in the later stage of fermentation;

[0044] (6) Add carbonized organic matter: add 0.01 part of carbonized...

Embodiment 3

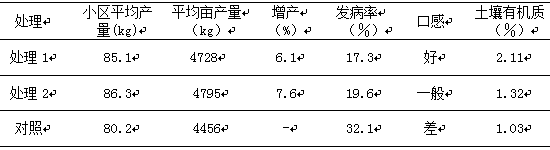

[0047] Embodiment 3: Application method of straw biogas slurry fertilizer

[0048] The invention further discloses the use method of straw biogas slurry fertilizer and its application and effect on cucumber planting. The method for using the straw biogas slurry fertilizer is characterized in that it is carried out according to the following steps:

[0049] 1. Dosage: 0.5 tons per mu;

[0050] 2. How to use: base application, deep plowing into the soil after application;

[0051] 3. Matters needing attention: Apply evenly to the soil to prevent seed germination and plant rooting from being affected by the concentration of straw in a certain plot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com