Organic protective coating used for low-treatment aluminum alloy surfaces

A pretreatment and slurry technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of reducing the compactness of the coating, poor adhesion and anti-corrosion of the substrate, and reduced anti-corrosion, so as to achieve high-efficiency anti-corrosion. effect, improve coating adhesion, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

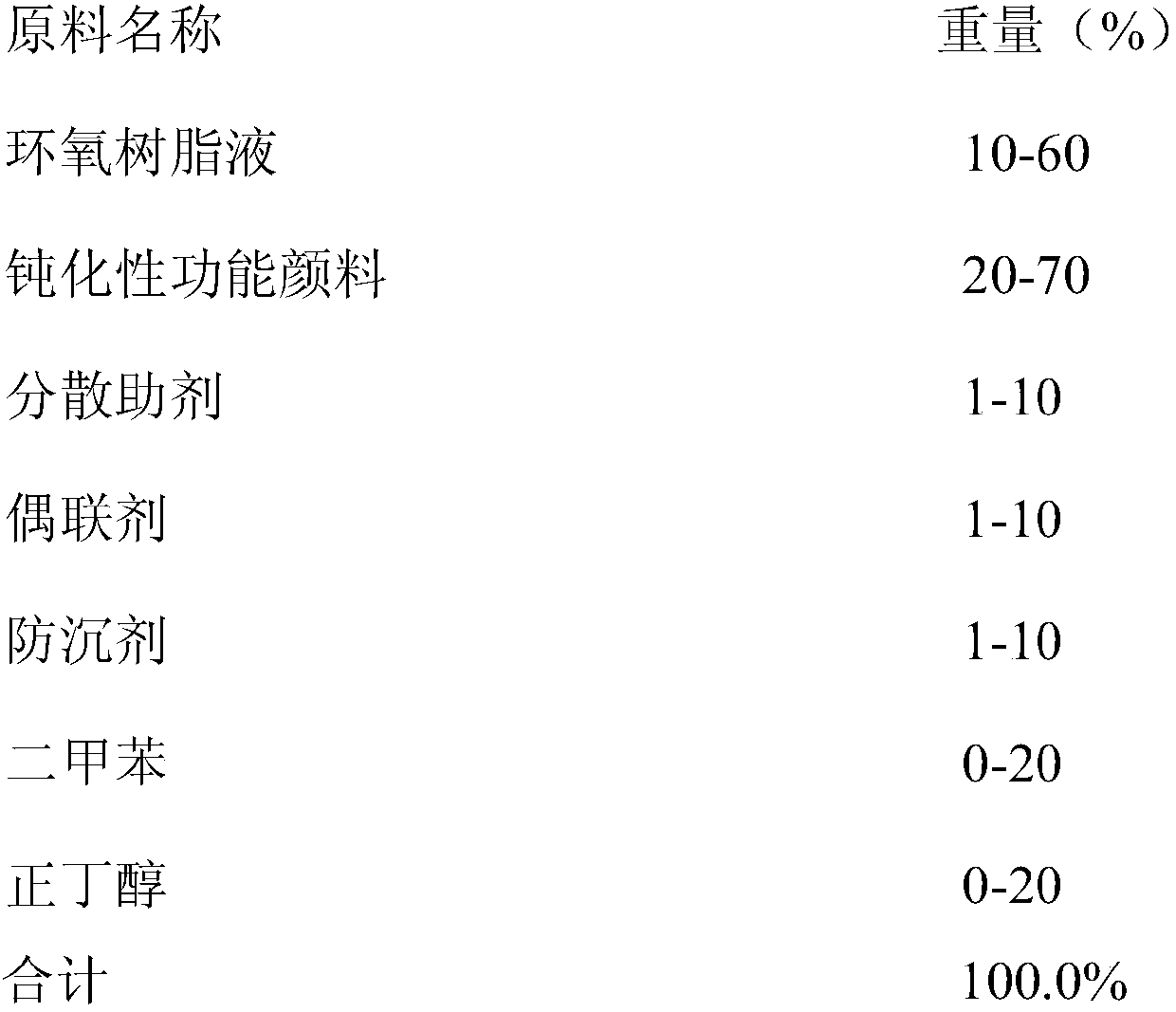

[0039] Example 1: Preparation of a pretreatment anticorrosive slurry 1

[0040]

[0041] Pretreatment anticorrosive slurry 1 preparation method: add formula amount of xylene and n-butanol into the container, place under high-speed stirring at 1000r / min, and add formula amount of BYK-P104S, 60% epoxy 601 in turn Liquid (the 60% epoxy 601 liquid is prepared by adding solid epoxy 601 resin to a mixed solvent of xylene and n-butanol under stirring), zinc chrome yellow, aluminum tripolyphosphate, disperse for 20 minutes, add Formulated Adherant 1121, disperse for 10 minutes, add anti-settling agent DeuRheo229 and continue to stir for 30 minutes to obtain a yellow viscous mixture with a stable pretreatment anticorrosive slurry 1 with a viscosity of 400-500 mPa.s.

Embodiment 2

[0042] Example 2: Preparation of a pretreatment anticorrosive slurry 2

[0043]

[0044]

[0045] The preparation method of pretreatment anticorrosive slurry 2 is: add formula amount of xylene and n-butanol into the container, place it under high speed stirring, rotate speed of 1500r / min, add formula amount of FX9086, 60% epoxy 604 liquid in turn (The 60% epoxy 604 liquid is prepared by adding solid epoxy 604 resin to the mixed solvent of xylene and n-butanol under stirring), zinc oxide, zinc phosphate, disperse for 15 minutes, and add the formulated amount of Adherant 1051, disperse for 10 minutes, add anti-settling agent BENGEL958 and continue stirring for 30 minutes to obtain a white viscous mixture with a stable pretreatment anticorrosive slurry with a viscosity of 600-700 mPa.s.

Embodiment 3

[0046] Example 3: Preparation of room temperature curing organic protective coating (HDD207) for low treatment aluminum alloy surface

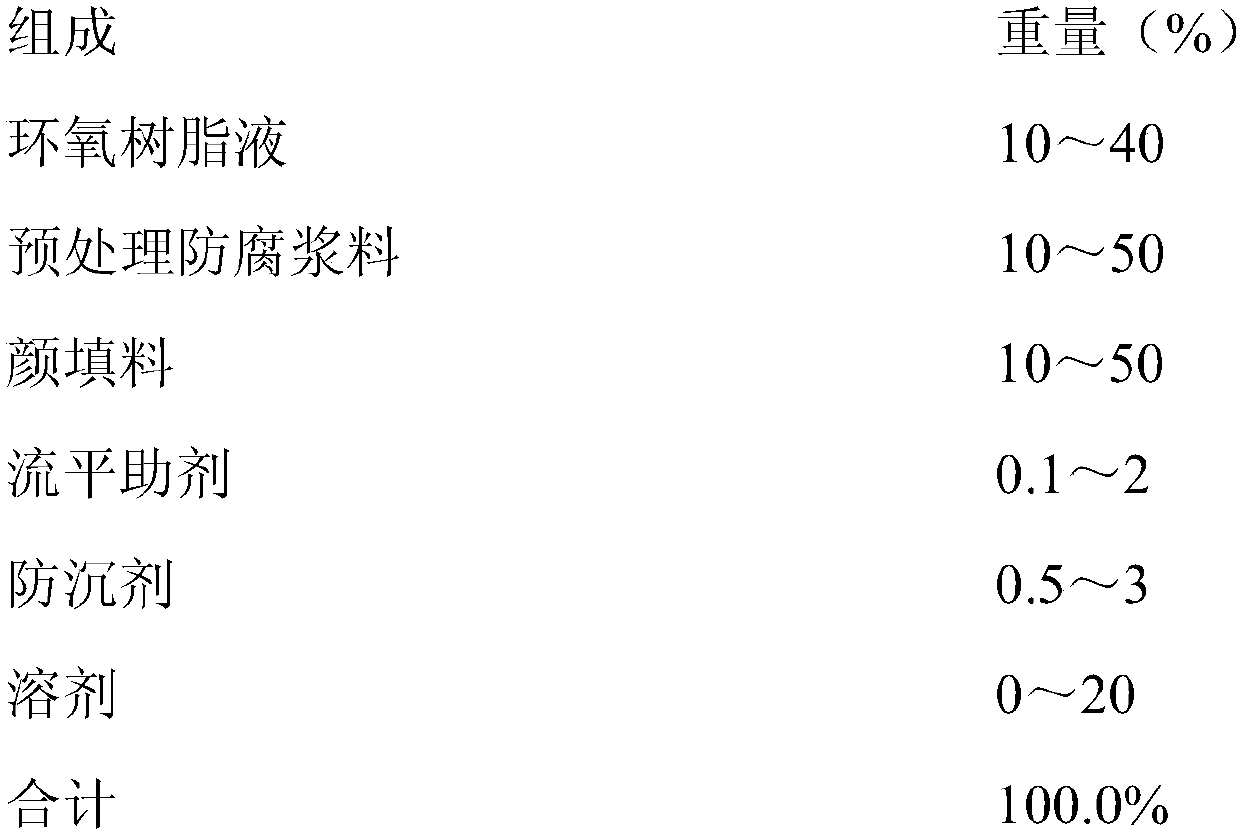

[0047] The formula of component A is as follows:

[0048]

[0049] Preparation method of component A: add 60% epoxy 601 liquid, Levaslip466, and solvent according to the above formula into a stirring vessel, stir at 800r / min for 20min until uniform; then add pretreatment anticorrosive slurry 1, 996 titanium dioxide, Calcium carbonate, aluminum powder, DeuRheo229, stir at 1000r / min for 30min until evenly dispersed, use sand mill to grind to a fineness of less than 60 microns, filter screen, weighing and packaging, to prepare A component color paste.

[0050] The formula of component B is as follows:

[0051]

[0052] The polyamide curing agent and the mixed solvent of xylene and n-butanol are stirred and dissolved to prepare the B component.

[0053] The A and B components are mixed and configured at a weight ratio of 5:1.

[0054] The coating can be app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com