A flue gas waste heat deep recovery system

A technology for recovering system and flue gas waste heat, applied in indirect heat exchangers, fluid heaters, heat exchanger types, etc. It can solve the problems of nonlinear energy conversion, energy waste, mismatch, etc. temperature, increase the dew point temperature, and improve the effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

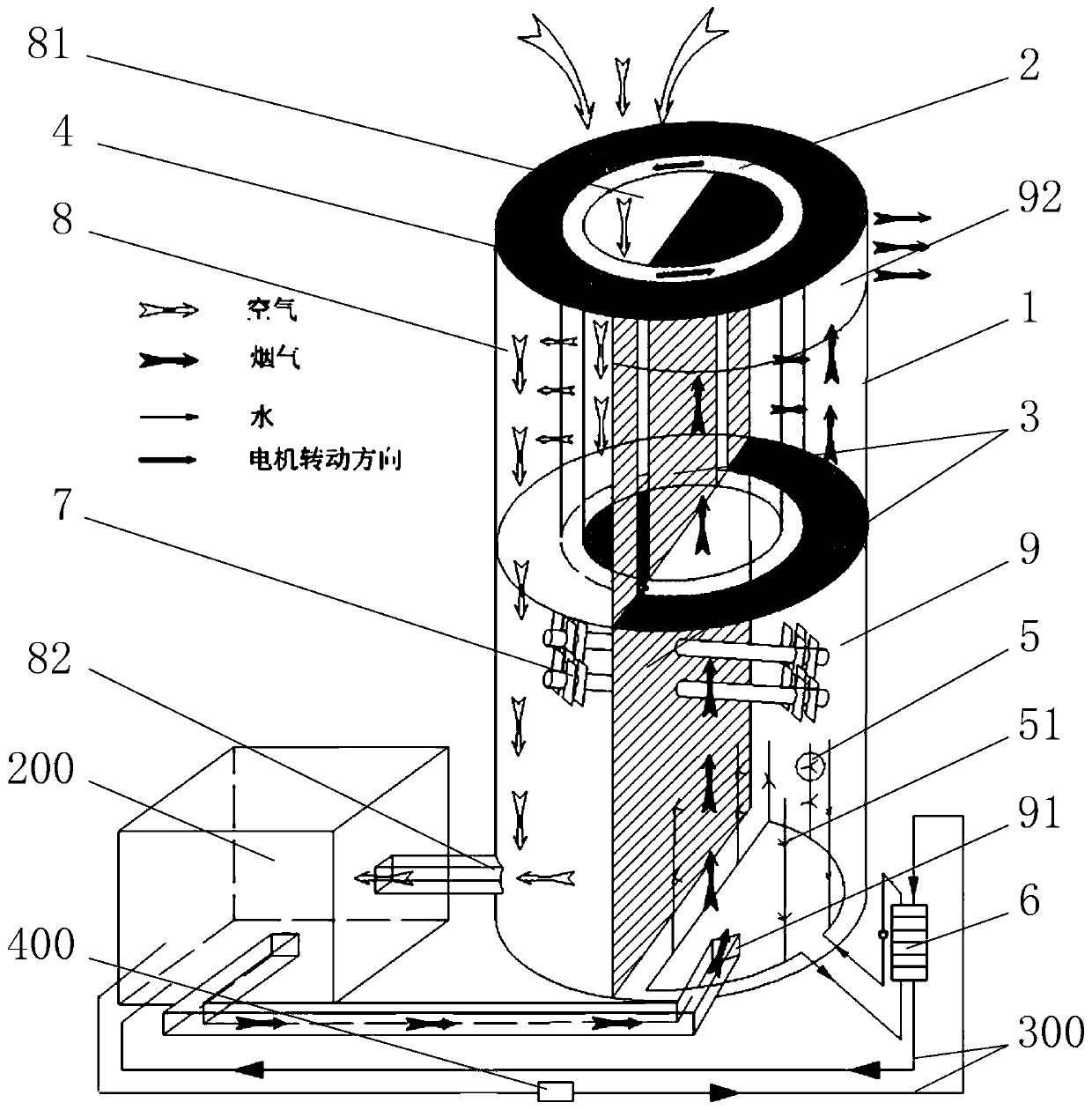

[0022] Such as figure 1 As shown, the flue gas waste heat deep recovery system provided by this embodiment includes a casing 1, a rotor 2, a partition 3, a baffle 4, a spray device 5, a water-to-water heat exchanger 6 and an air-flue gas exchange Heater7. Among them, the housing 1 is in the shape of a vertical thin-walled hollow cylinder; the rotating core 2 is in the shape of a vertical thick-walled hollow cylinder, and the side wall of the rotating core 2 is honeycomb-shaped and the honeycomb opening is horizontal, and the interior is filled with hygroscopic materials. The shaft is set in the upper part of the casing 1, and the rotating core 2 can rotate relative to its own central axis; the partition 3 divides the inner space of the casing 1 and the rotating core 2 into air through the central axis of the casing 1 and the rotating core 2. There are two parts, the flow channel 8 and the flue gas flow channel 9; a plurality of baffles 4 are respectively arranged between the ...

Embodiment 2

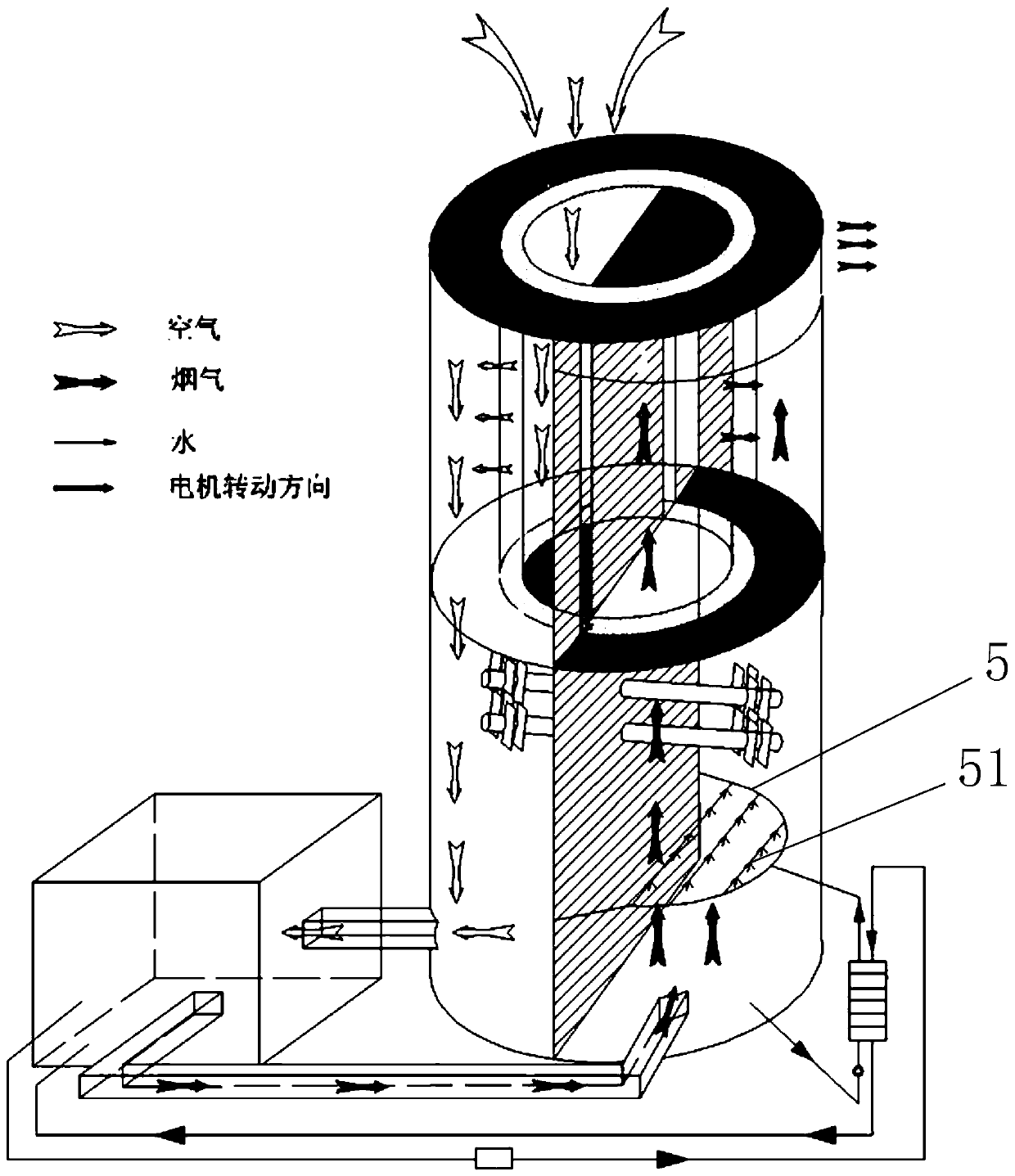

[0026] Such as figure 2 As shown, the flue gas waste heat deep recovery system provided in this embodiment has basically the same structure as that of Embodiment 1, the only difference is that in this embodiment, the liquid distributor 51 of the spray device 5 is arranged above the inlet 91 of the flue gas flow channel. The flue gas and the spray water are exchanged in countercurrent to obtain a better heat exchange effect.

[0027] In the above embodiments, the air-flue gas heat exchanger 7 is arranged below the liquid distributor 51 of the spray device 5, that is, after the flue gas enters the flue gas flow channel 9, it absorbs heat with the air-flue gas heat exchanger 7 first. end heat exchange, and then enter the spray device 5 to exchange heat with spray water.

Embodiment 3

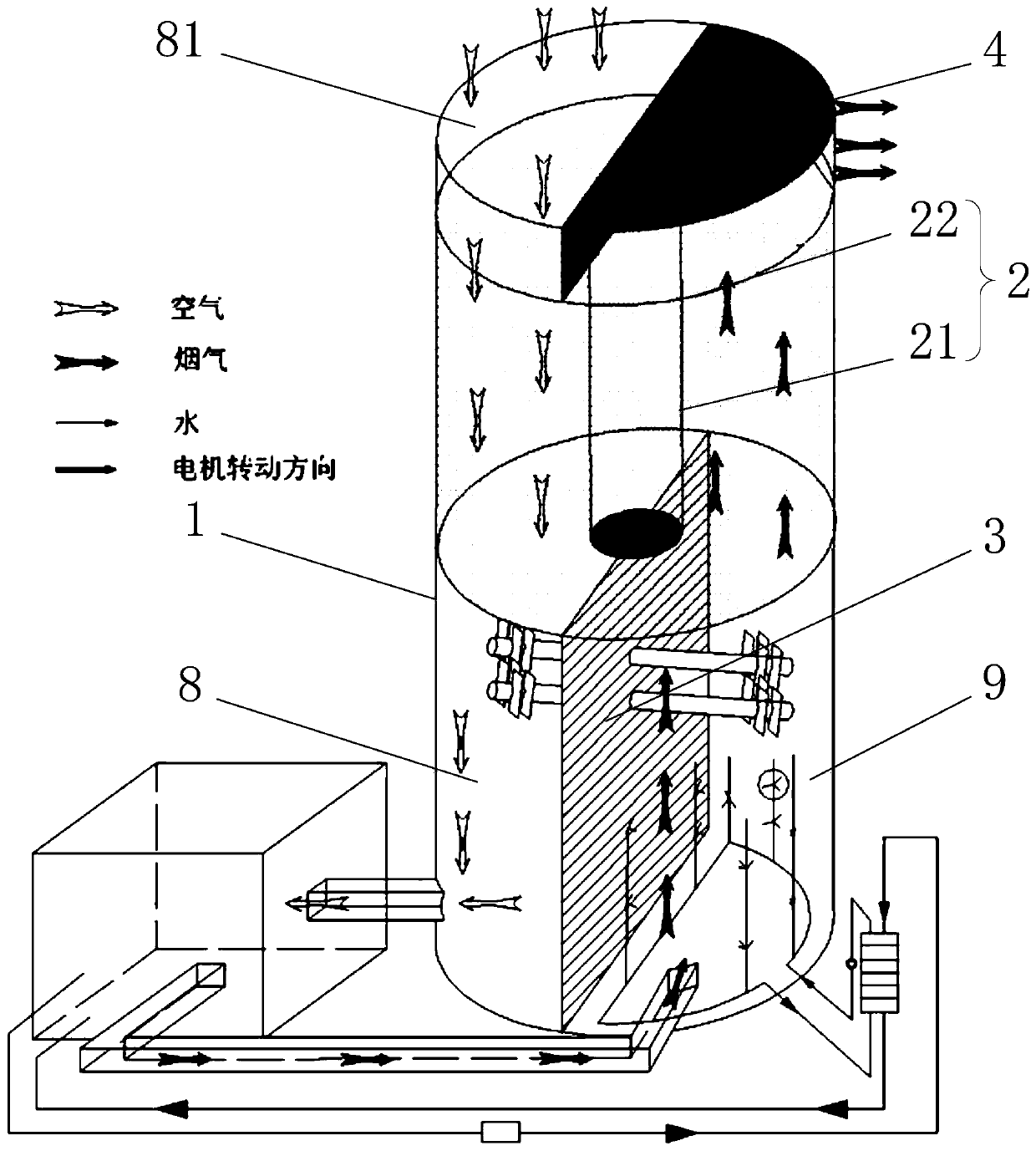

[0029] Such as image 3 As shown, the flue gas waste heat deep recovery system provided in this embodiment has basically the same structure as that of Embodiment 1, the only difference is that the rotating core 2 in this embodiment includes a central rotating shaft 21 and a surrounding runner 22, and the rotating wheel 22 adopts The honeycomb structure and the honeycomb opening are vertical, and the outer diameter of the runner 22 matches the inner diameter of the housing 1; since the air can only flow vertically in the runner 22, the partition 3 is only arranged under the rotor 2 In the housing 1, the inner space of the lower part of the housing 1 is divided into two parts: the air flow channel 8 and the smoke flow channel 9, and the baffle plate 4 only needs to be arranged on the top of the rotor core 2 on the side of the smoke flow channel 9 and Between the top of the housing 1. When the flue gas waste heat deep recovery system of this embodiment is in use, the air passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com