Environment-friendly tobacco drying room based on natural gas burner for energy supply

A natural gas and burner technology, which is applied in the fields of tobacco, tobacco preparation, and application, can solve the problems of temperature stabilization, difficult to control the heating rate, very difficult technical mastery, and influence on the quality of tobacco curing, so as to reduce the loss of tobacco curing. , The effect of reducing the labor and labor intensity of adding coal, and improving the enthusiasm for planting tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

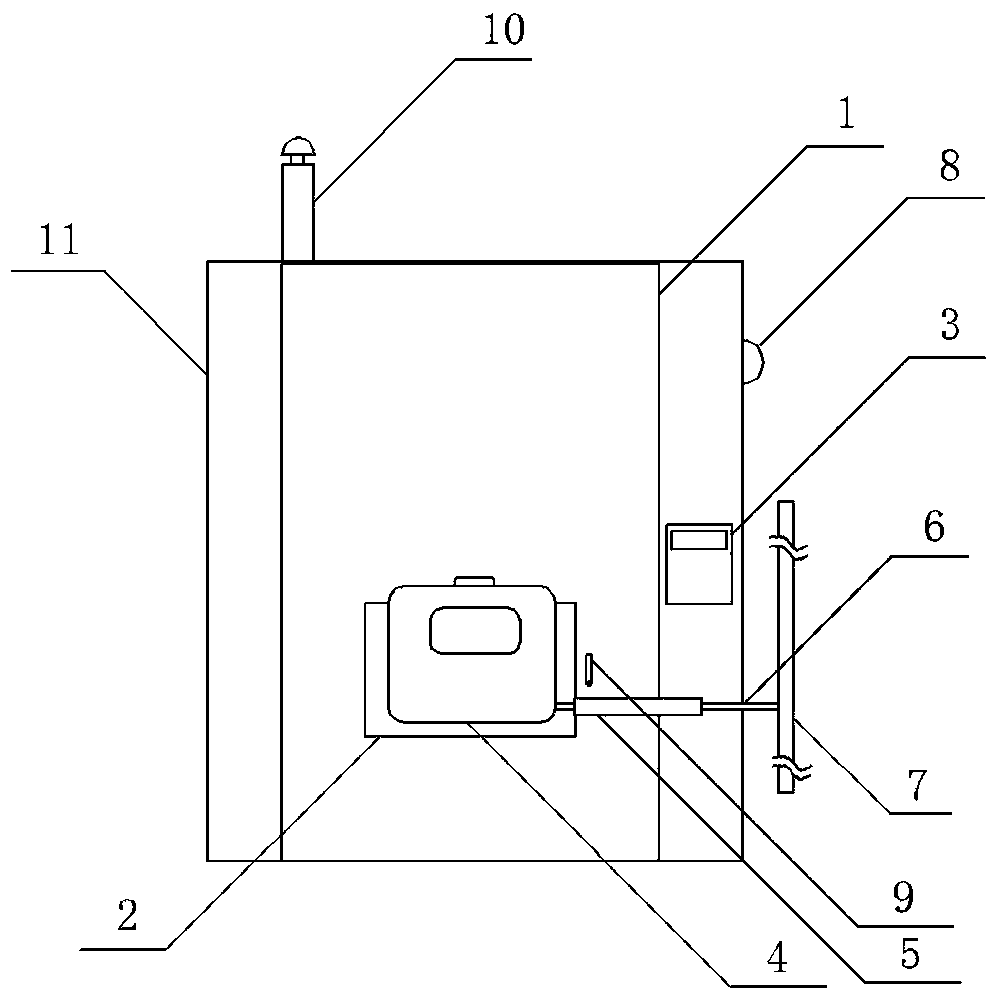

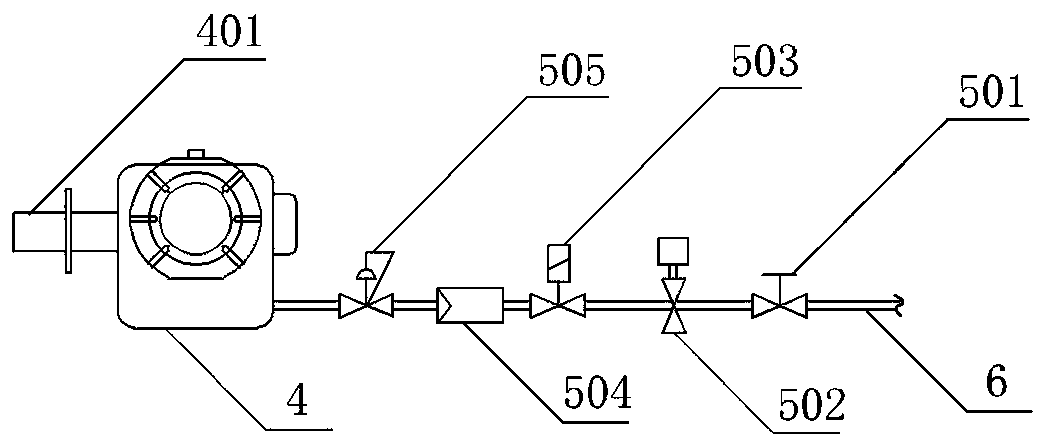

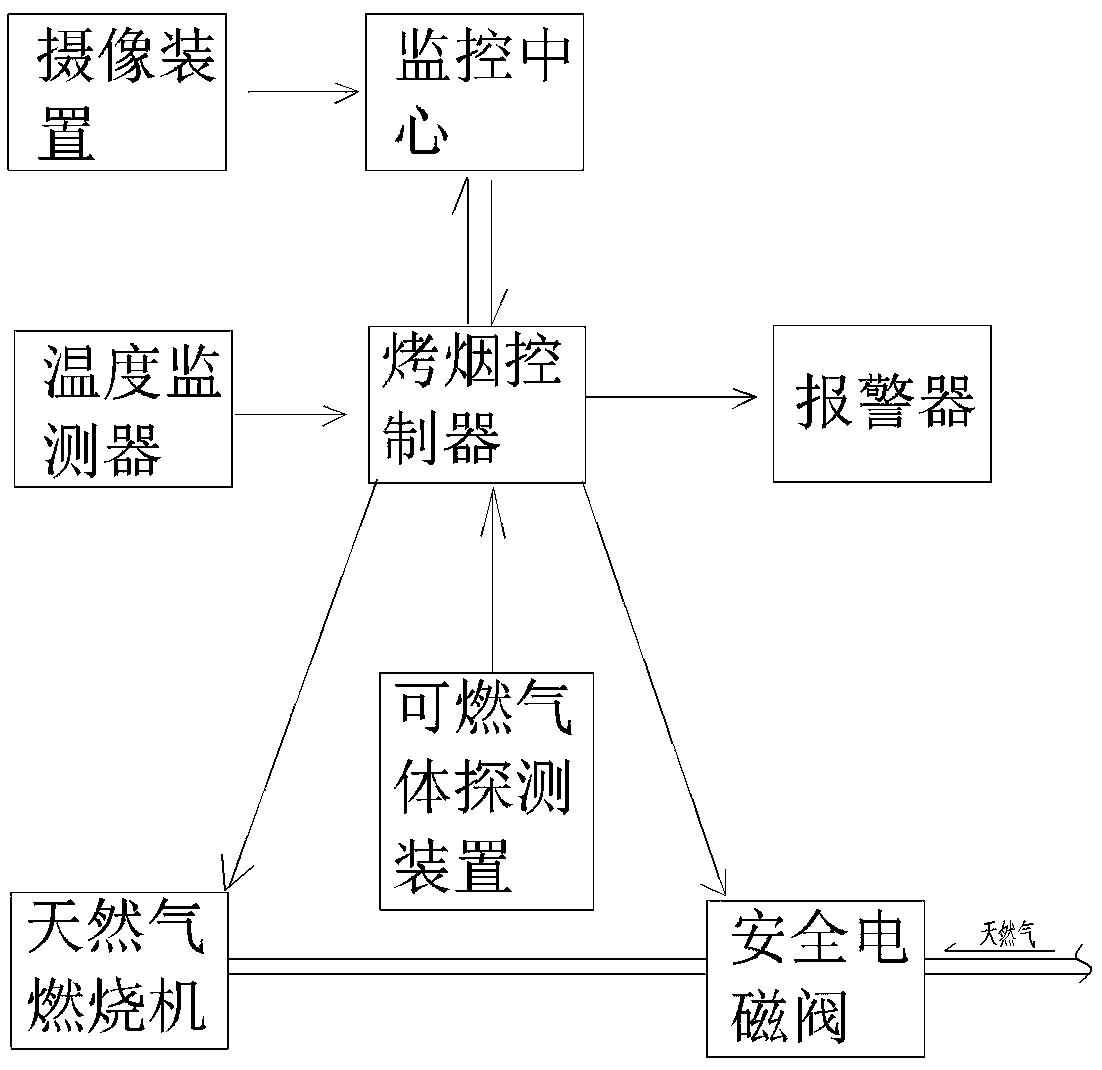

[0017] Such as figure 1 - image 3 The present invention shown includes a heating chamber 1, a natural gas burner 4, a natural gas control valve group 5, a temperature monitor, a flue-cured tobacco controller 3, and an alarm 8. The lower part of the heating chamber 1 is provided with a furnace hall, and the upper part is provided with a circulating air chamber. The upper part is connected with the flue 10, the front part is provided with a furnace mouth, and the furnace door is provided with a furnace door 2, and an opening is arranged on the furnace door 2, and the combustion head 401 of the natural gas burner 4 passes through the furnace door opening and is connected with the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com