Indium-based MOF micro-nano powder as well as room temperature preparation method and application thereof

A micro-nano, indium-based technology, applied in chemical instruments and methods, other chemical processes, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of restricting development and industrial application, restricting application and development, etc., To achieve the effect of simplifying operation, improving adsorption, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] (1) Configuration of solution A: Dissolve 2mmol terephthalic acid in 25mL N,N-dimethylformamide (DMF), stir for 10min, and set aside;

[0075] (2) Configuration of solution B: 2mmol indium nitrate was dissolved in 5mL water and formed a uniform solution;

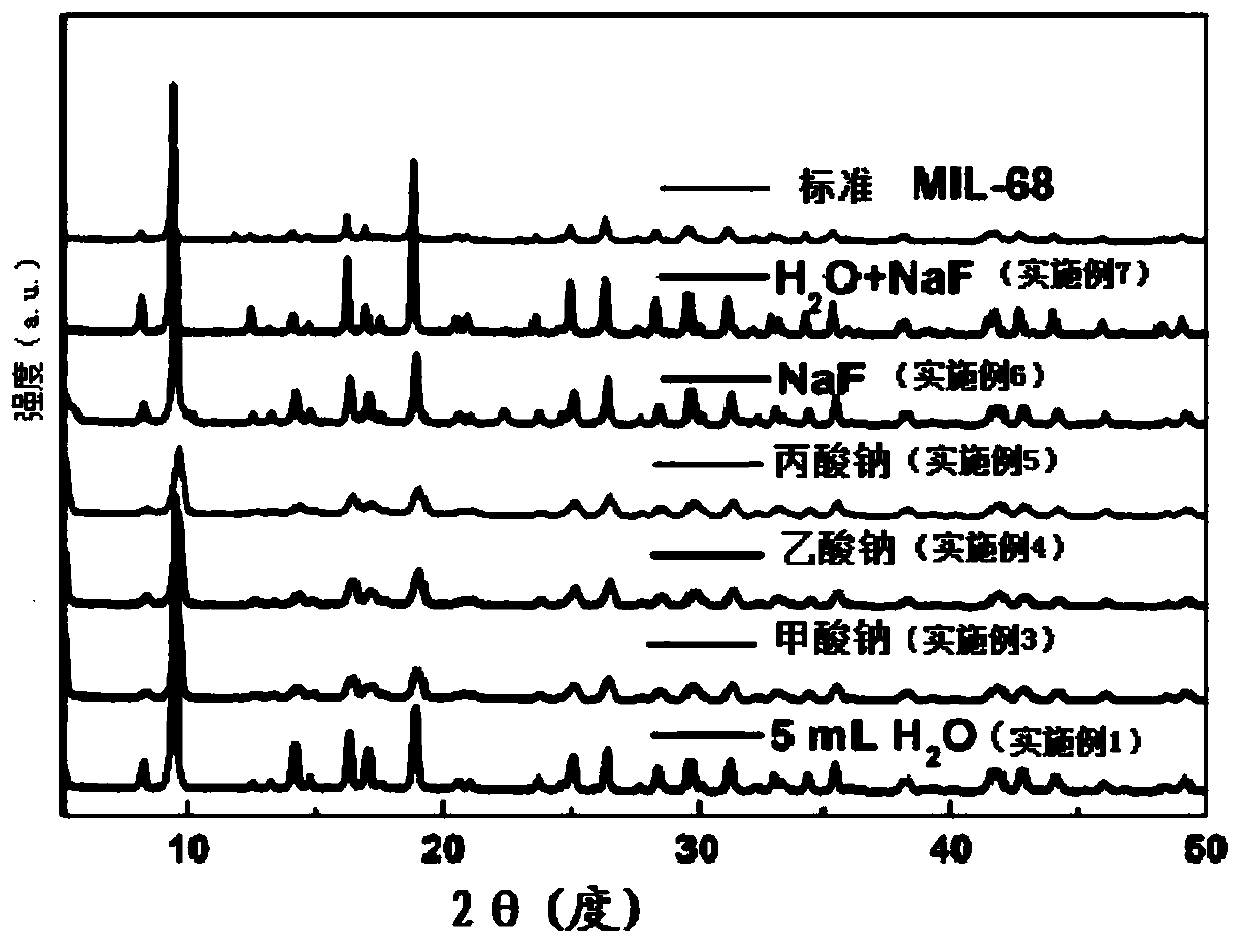

[0076] (3) Pour solution B into solution A, continue to stir and react at a temperature of 25°C for 24 hours, centrifuge, wash with ethanol twice, and dry to obtain a rod-shaped MIL-68(In) micro-nano material. The electron micrograph of the material is as follows Figure 4a Shown (the magnification of electron micrograph is 10k), its XRD pattern is as follows figure 1 shown. figure 1 Among them, the standard MIL-68 refers to the XRD structure of the known standard MIL-68, which is determined by figure 1 It can be seen that the embodiment of the present invention successfully prepared indium-based MIL-68 with XRD diffraction characteristic peaks of the standard product.

Embodiment 2

[0078] (1) Configuration of solution A: Dissolve 2mmol terephthalic acid in 20mL N,N-dimethylformamide (DMF), stir for 10min, and set aside;

[0079] (2) Configuration of solution B: 2mmol indium nitrate is dissolved in 10mL water and form a uniform solution;

[0080] (3) Pour solution B into solution A, continue to stir and react at a temperature of 25°C for 24 hours, centrifuge, wash with ethanol twice, and dry to obtain a rod-shaped MIL-68(In) micro-nano material. The electron micrograph of the material is as follows Figure 4b Shown (the magnification of the electron micrograph is 10k).

[0081] Depend on Figure 4b and Figure 4a It can be seen that in the method of the present invention, the more water is added, the more inhomogeneous the material morphology will be.

[0082] After repeated studies, the inventors have shown that when preparing an aqueous solution of indium nitrate, the water added should not be too much, too much will make the appearance of the prepar...

Embodiment 3

[0084] (1) Configuration of solution A: Dissolve 2mmol terephthalic acid in 25mL N,N-dimethylformamide (DMF), stir for 10min, add 50mg sodium formate to it, and set aside;

[0085] (2) Configuration of solution B: 2mmol indium nitrate is dissolved in 5mL DMF and form a uniform solution;

[0086] (3) Pour solution B into solution A, continue to stir and react at a temperature of 25°C for 24 hours, centrifuge, wash with ethanol twice, and dry to obtain a rod-shaped MIL-68(In) micro-nano material, its XRD pattern is as follows figure 1 shown. figure 1 Among them, the standard MIL-68 refers to the XRD structure of the known standard MIL-68, which is determined by figure 1 It can be seen that the examples of the present invention have successfully prepared indium-based MIL-68 with XRD diffraction characteristic peaks of the standard product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com