A method for realizing short-cut nitrification and denitrification by using high light intensity

A short-range nitrification and denitrification technology is applied in the field of sewage treatment technology to achieve the effects of reducing reaction costs, reducing sludge production and saving aeration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

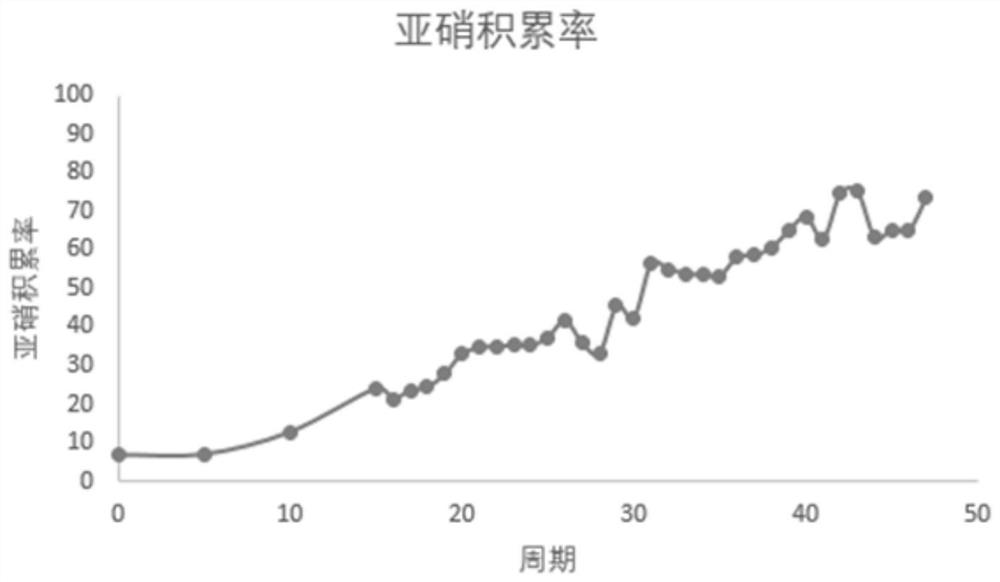

[0021] Example 1: Direct irradiation of nitrifying bacteria with a cold light source high light intensity plate

[0022] The nitrifying bacteria that have been domesticated for a long time are subjected to nitrification and denitrification through SBR under high light intensity direct irradiation. Each cycle includes water inflow for 1 minute, anoxic for 1 hour, aerobic for 2.25 hours, precipitation for 1 hour, and drainage for 5 minutes. The mixture was mixed uniformly by a magnetic stirrer, and the -2 the s -1 Under light intensity irradiation, aeration is carried out by an air pump with an air stone. NOB showed certain photosensitivity under high light intensity, and gradually formed the accumulation of nitrite nitrogen.

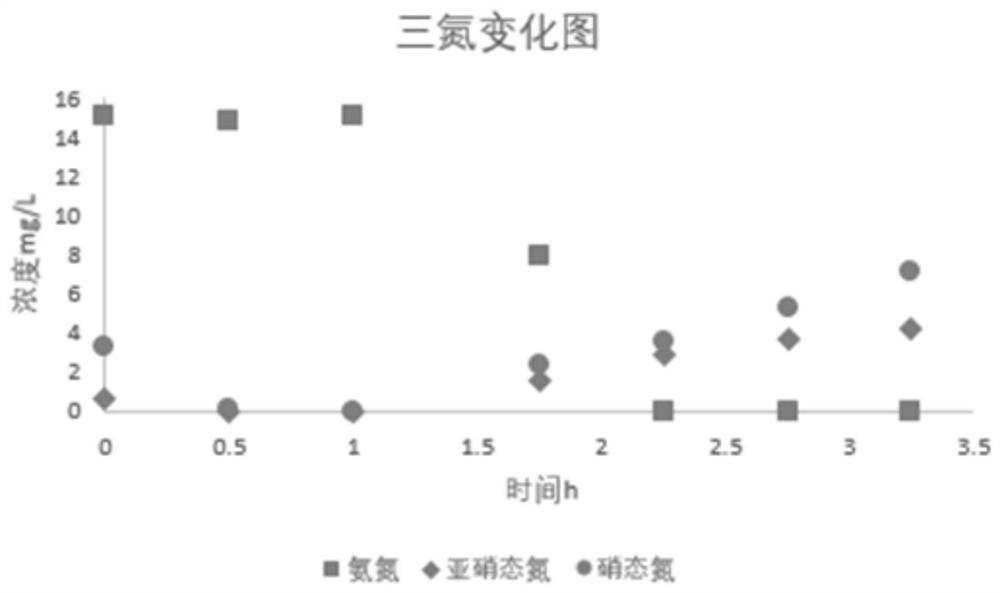

[0023] Such as figure 1 As shown, in the 25th period of long-term culture, in the first hour of hypoxia, the concentration of ammonia nitrogen remained basically unchanged, and nitrite nitrogen and nitrate nitrogen were reduced to nitrogen; The concentr...

Embodiment 2

[0024] Example 2: Indirect irradiation of nitrifying bacteria using a cold light source high light intensity plate

[0025] The nitrifying bacteria that have been domesticated for a long time will be nitrified and denitrified by SBR under the indirect irradiation of high light intensity. -2 the s -1 The light intensity was irradiated for 3 hours under high light intensity, and at the same time, the mixture was uniformly mixed by a magnetic stirrer. Then stop the light, and carry out nitrification and denitrification through water inflow, including water inflow for 1min, anoxic for 0.5h, aerobic for 1.5h, sedimentation for 1h, and drainage for 5min. Aerate. NOB showed a certain photosensitivity and gradually formed the accumulation of nitrite nitrogen.

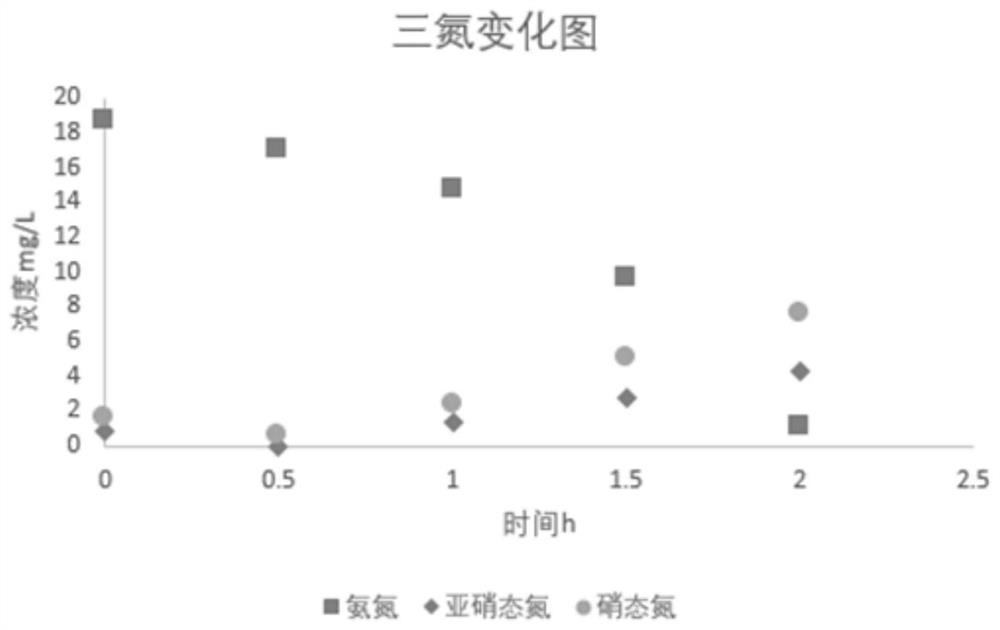

[0026] Such as image 3 As shown, in the 40th cycle of long-term cultivation, after 3 hours of light, then stop the light, and carry out nitrification and denitrification through water inflow. and nitrate nitrogen were red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com