Wear-resistant wood-plastic floor and manufacturing method

A technology of wood-plastic floor and manufacturing method, which is applied in the field of wood-plastic floor, can solve problems such as high cost, difficult preparation, and complicated production process, and achieve the effects of low cost, reduced oxidation rate, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

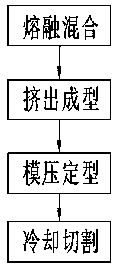

Method used

Image

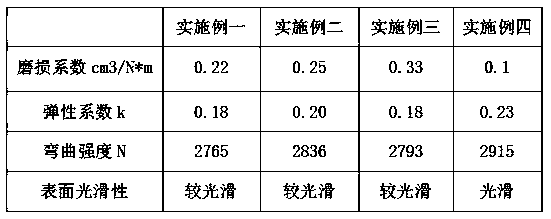

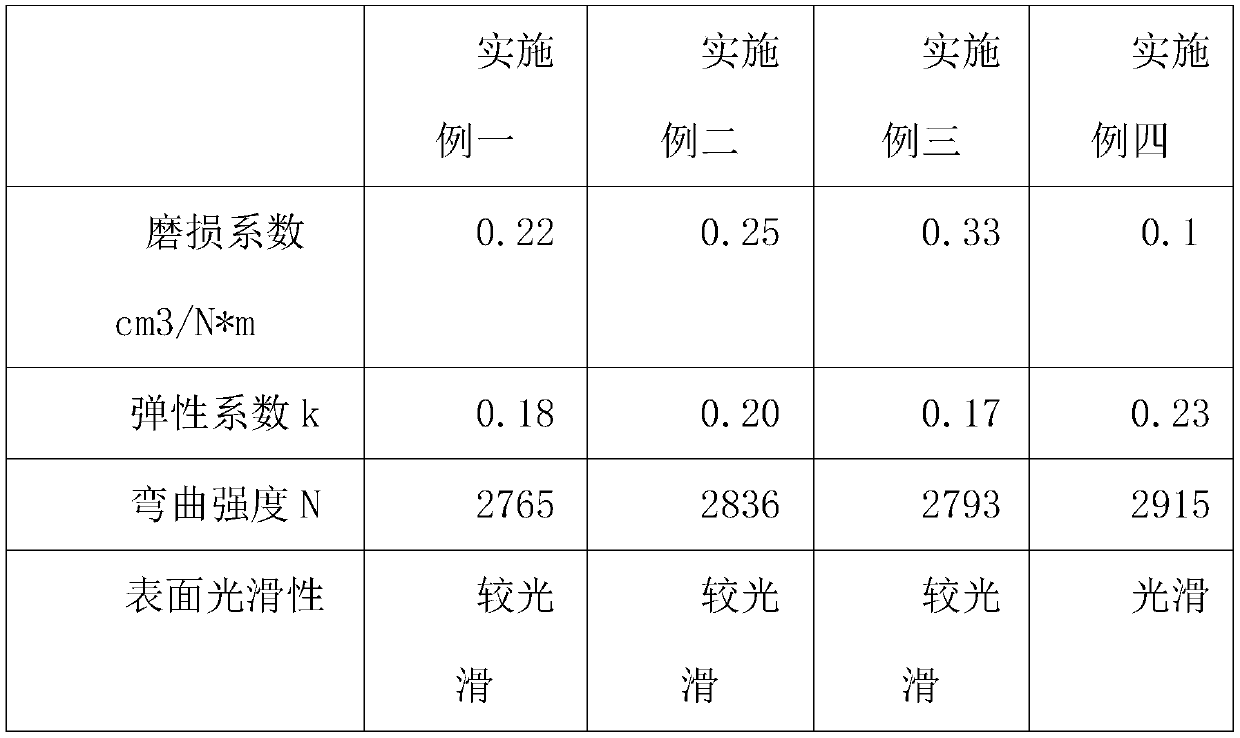

Examples

Embodiment 1

[0055] A wear-resistant wood-plastic floor is made of the following raw materials in parts by weight:

[0056] 35-38 copies of PET;

[0057] 30-35 parts of plant fiber;

[0058] 8-9 parts of aluminum oxide;

[0059] 2 to 5 parts of coloring agent;

[0060] 2 to 3 parts of plasticizer;

[0061] 4-7 parts of stabilizer;

[0062] 3 to 4 parts of lubricant.

[0063] Further, the PET materials are recycled mineral water bottles and carbonated beverage bottles; the plant fibers are made of rice husks, rice straw, wheat straw, corn straw, cotton stalks, wood chips, bamboo chips and other crop straws or stems of other plants. 10-200 mesh plant fiber powder, and then use special technology to make mixed raw materials; plasticizers are phthalates, terephthalates, benzoates, benzoates, polyol esters One of them, epoxies, citric acid esters and polyesters, preferably polyol lipids; the coloring agent is one of organic dyes and inorganic pigments, preferably organic dyes.

[0064] A...

Embodiment 2

[0071] A wear-resistant wood-plastic floor is made of the following raw materials in parts by weight:

[0072] 38-41 copies of PET;

[0073] 35-38 parts of plant fiber;

[0074] 9-10 parts of aluminum oxide;

[0075] 2 to 5 parts of coloring agent;

[0076] 2 to 3 parts of plasticizer;

[0077] 4-7 parts of stabilizer;

[0078] 3 to 4 parts of lubricant.

[0079] Further, the PET materials are recycled mineral water bottles and carbonated beverage bottles; the plant fibers are made of rice husks, rice straw, wheat straw, corn straw, cotton stalks, wood chips, bamboo chips and other crop straws or stems of other plants. 10-200 mesh plant fiber powder, and then use special technology to make mixed raw materials; plasticizers are phthalates, terephthalates, benzoates, benzoates, polyol esters One of them, epoxies, citric acid esters and polyesters, preferably polyol lipids; the coloring agent is one of organic dyes and inorganic pigments, preferably organic dyes.

[0080] ...

Embodiment 3

[0087] A wear-resistant wood-plastic floor is made of the following raw materials in parts by weight:

[0088] 38-41 copies of PET;

[0089] 30-35 parts of plant fiber;

[0090] 9-10 parts of aluminum oxide;

[0091] 2 to 5 parts of coloring agent;

[0092] 2 to 3 parts of plasticizer;

[0093] 4-7 parts of stabilizer;

[0094] 3 to 4 parts of lubricant.

[0095] Further, the PET materials are recycled mineral water bottles and carbonated beverage bottles; the plant fibers are made of rice husks, rice straw, wheat straw, corn straw, cotton stalks, wood chips, bamboo chips and other crop straws or stems of other plants. 10-200 mesh plant fiber powder, and then use special technology to make mixed raw materials; plasticizers are phthalates, terephthalates, benzoates, benzoates, polyol esters One of them, epoxies, citric acid esters and polyesters, preferably polyol lipids; the coloring agent is one of organic dyes and inorganic pigments, preferably organic dyes.

[0096] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com