Directional high-heat-conductivity ultrathin single-side adhesive tape and double-side adhesive tape

A technology of high thermal conductivity and thermally conductive adhesive, applied in the direction of adhesives, film/sheet release coatings, film/sheet adhesives, etc., can solve problems such as uneven heat dissipation, unreliable use, and insufficient thermal conductivity. Achieve the effects of improving thermal conductivity and heat dissipation uniformity, improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

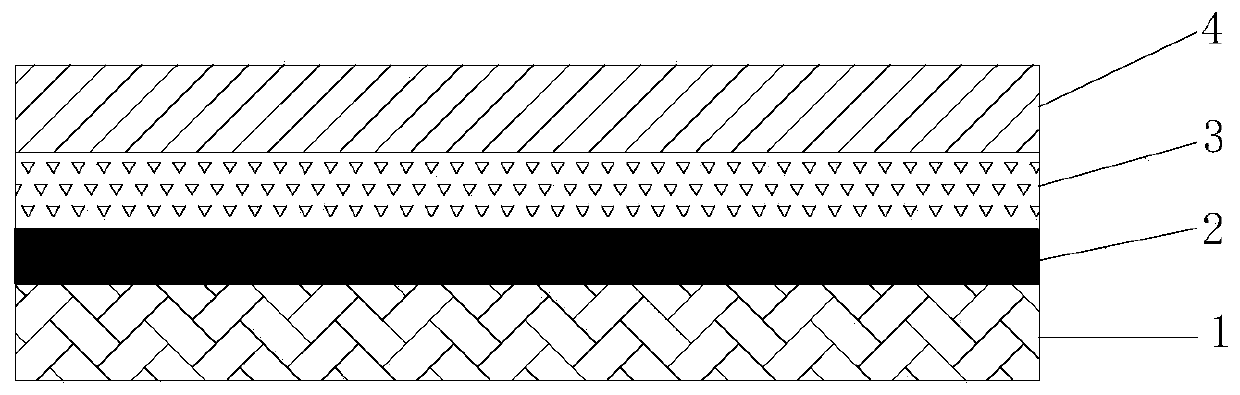

[0026] Such as figure 1 As shown, an ultra-thin single-sided tape with directional high thermal conductivity includes a base layer 1, and a first heat conduction layer 2, a first heat conduction adhesive layer 3 and a first release film layer 4 sequentially arranged on the base layer;

[0027] Wherein, the first thermally conductive adhesive layer is formed by mixing, coating and baking the following materials in parts by weight: 100 parts of silica gel adhesive, 45 parts of inorganic thermal conductive filler, 12 parts of graphene, 10 parts of curing agent, 3 parts of coupling agent, 5 parts of flame retardant, solvent 180; The curing agent is a polythiol curing agent, the coupling agent is a silane coupling agent, and the solvent is acetone; It includes: 20 parts of aluminum nitride powder, 15 parts of silicon micropowder, 8 parts of zirconium diboride powder, 5 parts of hafnium carbide micropowder, and 16 parts of beryllium oxide ceramic micropowder.

[0028] Wherein, the ...

Embodiment 2

[0032] Such as figure 1 As shown, an ultra-thin single-sided tape with directional high thermal conductivity includes a base layer 1, and a first heat conduction layer 2, a first heat conduction adhesive layer 3 and a first release film layer 4 sequentially arranged on the base layer;

[0033]Wherein, the first thermally conductive adhesive layer is formed by mixing, coating, and baking the following materials in parts by weight: 80 parts of silica gel adhesive, 35 parts of inorganic thermal conductive filler, 8 parts of graphene, 8 parts of curing agent, 1 part of coupling agent, 3 parts of flame retardant, 150 parts of solvent; the curing agent is a polythiol curing agent, the coupling agent is a silane coupling agent, and the solvent is methyl acetate; the inorganic thermally conductive filler It includes by weight: 30 parts of aluminum nitride powder, 25 parts of silicon micropowder, 14 parts of zirconium diboride powder, 3 parts of hafnium carbide micropowder, and 12 part...

Embodiment 3

[0038] like figure 1 As shown, an ultra-thin single-sided tape with directional high thermal conductivity includes a base layer 1, and a first heat conduction layer 2, a first heat conduction adhesive layer 3 and a first release film layer 4 sequentially arranged on the base layer;

[0039] Wherein, the first thermally conductive adhesive layer is formed by mixing, coating, and baking the following materials in parts by weight: 90 parts of silica gel adhesive, 40 parts of inorganic thermal conductive filler, 10 parts of graphene, 9 parts of curing agent, 2 parts of coupling agent, 4 parts of flame retardant, solvent 165; Described curing agent is polythiol curing agent, and described coupling agent is silane coupling agent, and described solvent is ethanol and methyl acetate (volume ratio 1 : 1) mixed solvent; the inorganic thermally conductive filler includes by weight: 25 parts of aluminum nitride powder, 20 parts of silicon micropowder, 11 parts of zirconium diboride powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com