A kind of high-strength high-corrosion-resistant magnesium alloy and preparation method thereof

A magnesium alloy, high corrosion resistance technology, applied in the field of materials, can solve the problems of slightly poor absolute strength and elongation, poor plastic forming ability, poor formability, etc. The effect of crystal nucleation points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

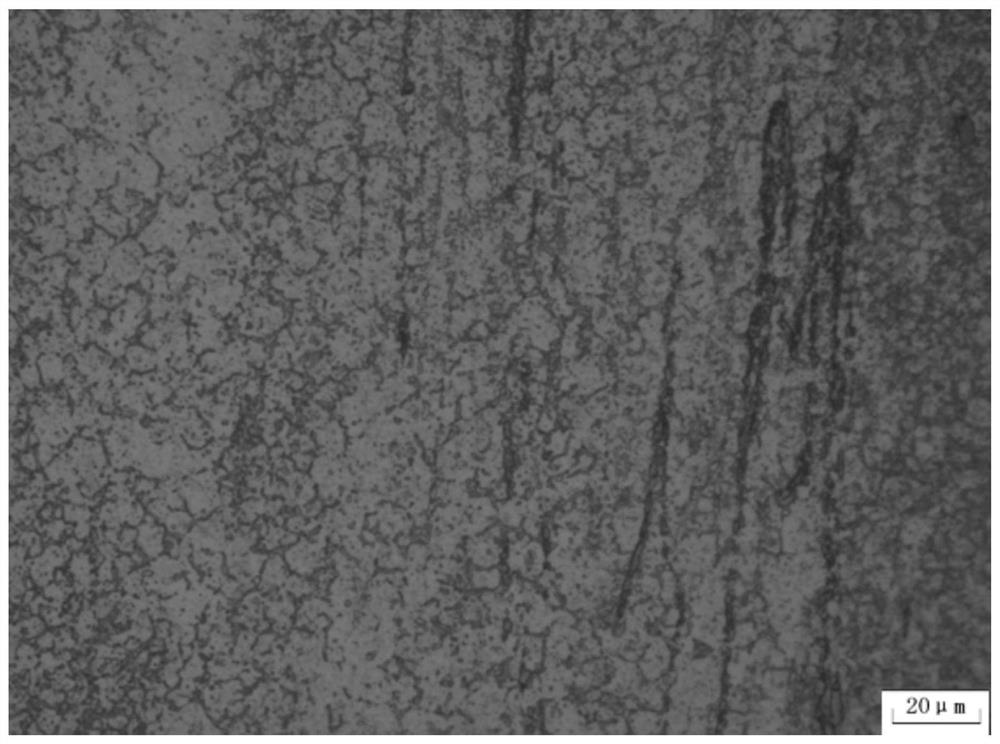

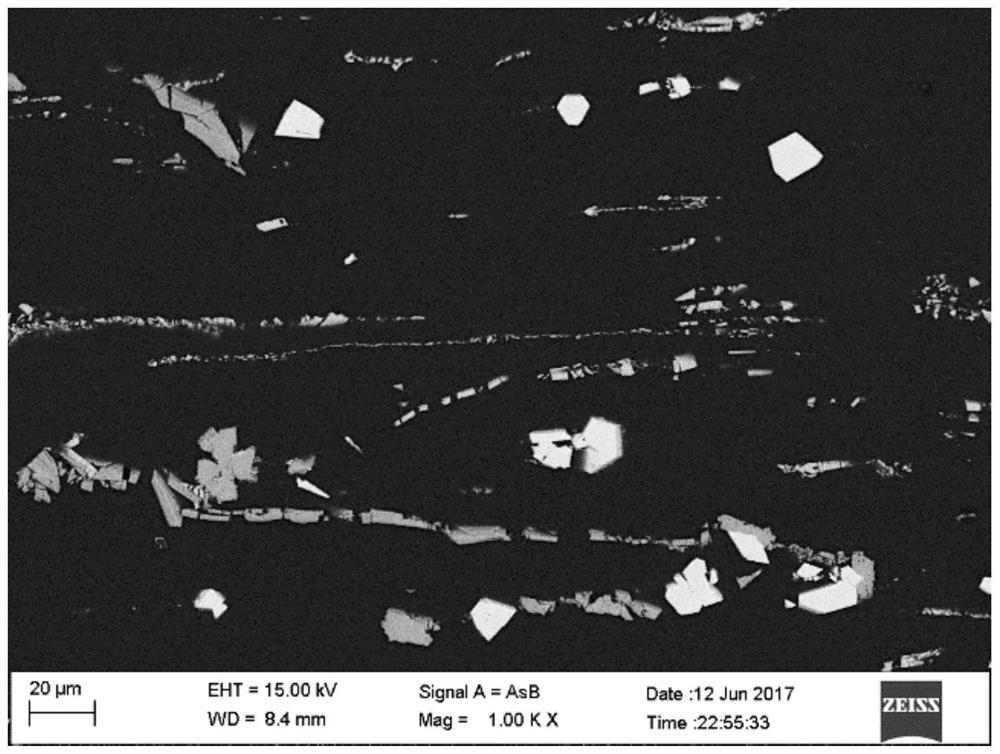

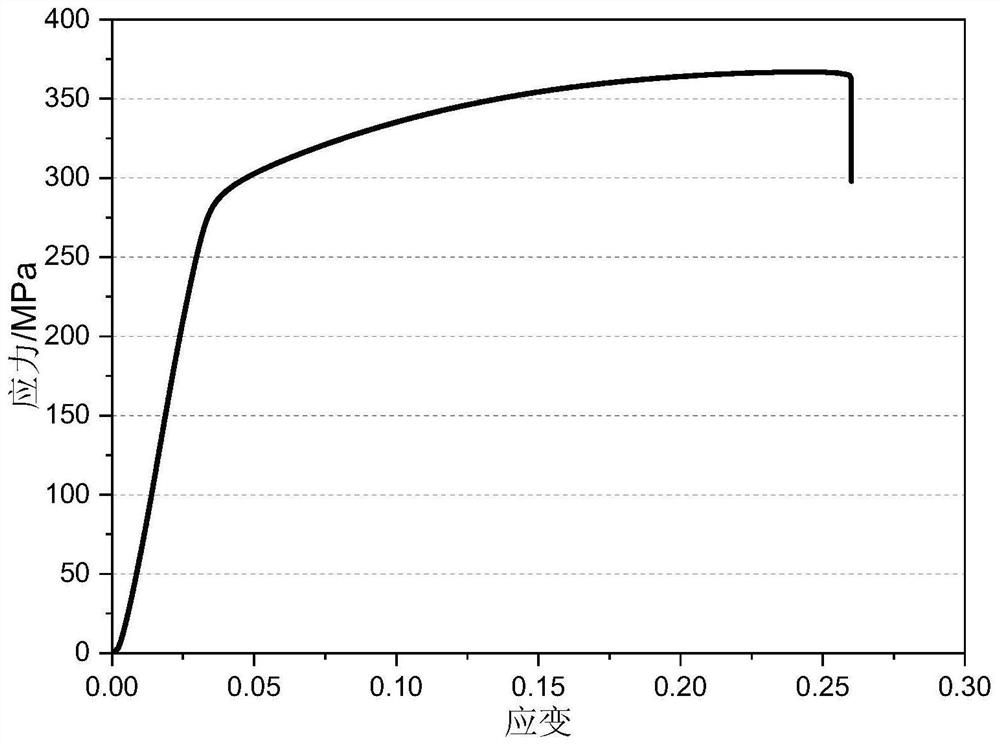

Image

Examples

Embodiment 1

[0041] Prepare magnesium ingot, zinc block, aluminum block, manganese chloride particles and Mg-rich La mixed rare earth master alloy, which contains La and Ce 30% by weight percentage in the described Mg-rich La mixed rare earth master alloy, and La / Ce The weight ratio of manganese chloride particles is 2:1; the particle size of manganese chloride particles is 1-3mm;

[0042] The No. 5 flux prepared is 0.2% of the total weight of magnesium ingot, zinc block, aluminum block, manganese chloride and Mg-La-rich mixed rare earth master alloy;

[0043] Under the condition of protective atmosphere, put the magnesium ingot into the smelting resistance furnace to melt, set the temperature of the material to 750±5°C, and obtain the magnesium melt; the protective atmosphere is an argon atmosphere;

[0044] in SF 6 with CO 2 Under the condition of mixed protective atmosphere, the aluminum block is melted in another melting resistance furnace, and the melting temperature is 750±5°C to obt...

Embodiment 2

[0052] Method is with embodiment 1, and difference is:

[0053] (1) prepare magnesium ingot, zinc block, aluminum block and Mg-rich La mixed rare earth master alloy, contain La and Ce 20% by weight percentage in the described Mg-rich La mixed rare earth master alloy, and the weight of La / Ce The ratio is 3:1;

[0054] (2) No. 5 flux is 0.3% of the total weight of magnesium ingot, zinc block, aluminum block and Mg-La-rich mixed rare earth master alloy; no manganese chloride is added;

[0055] (3) Refining at 750±5°C for 35 minutes after adding the mixed solution to the magnesium melt, then standing for 40 minutes, and cooling down to 695°C during the standing process;

[0056] (4) In a mixed protective atmosphere, SF 6 with CO 2 The volume ratio is 1:4;

[0057] (5) The equal area corrosion weight of the corrosion test is 16mg / cm 2 ;

[0058] (6) The temperature of the first level homogenization treatment is 200°C, and the time is 7h; the temperature of the second level ho...

Embodiment 3

[0062] Method is with embodiment 1, and difference is:

[0063] (1) The Mg-La-rich mixed rare earth master alloy contains a total of 25% of La and Ce by weight percentage;

[0064] (2) No. 5 flux is 0.4% of the total weight of magnesium ingot, zinc block, aluminum block, manganese chloride and Mg-La-rich mixed rare earth master alloy;

[0065] (3) After the mixed solution is added to the magnesium melt, it is refined at 750±5°C for 40 minutes, then it is left to stand for 0 minutes, and the temperature is lowered to 695°C during the standing process;

[0066] (4) In a mixed protective atmosphere, SF 6 with CO 2 The volume ratio is 1:5;

[0067] (5) The equal area corrosion weight of the corrosion test is 13mg / cm 2 ;

[0068] (6) The temperature of the first level homogenization treatment is 220°C, and the time is 6h; the temperature of the second level homogenization treatment is 400°C, and the time is 12h;

[0069] (7) The ingot is kept at 310°C for 1.5h, and then hot-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com