Preparation process of baking raw paper

A preparation process and baking technology, applied in the field of preparation technology of baking base paper, can solve the problems of high cost, complex process, incomplete quality of paper, etc., and achieve the effects of improving stiffness, reducing paper dust, and improving dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

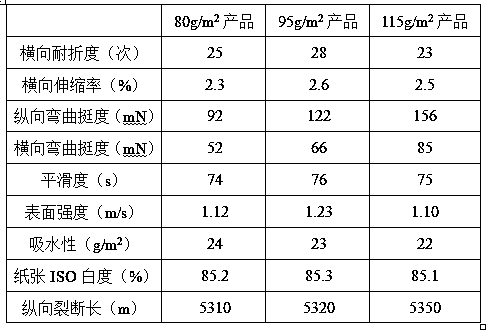

Embodiment 1

[0018] The purchased bleached softwood kraft pulp is beaten to 48°SR, and the bleached hardwood kraft pulp is beaten to 40°SR. In the beating process of NBKP and LBKP, 0.3kg / t of cellulase is added respectively; Seed pulp is prepared according to the proportions of 35% bleached softwood kraft pulp and 65% bleached hardwood kraft pulp. After mixing, the pulp is formulated into a pulp with a concentration of 3.5%. The pulp is screened through a thick pulp sieve, and 6kg / is added in the seasoning section. t paper starch enhancer, add 5kg / t paper calcium sulfate at the same time, and then pour pulp. In the pulping section, add wet strength agent with a dosage of 5kg / t paper, and then go through desanding and degassing, sizing, fine sieving, and online molding Dewatering, pressing, pre-drying, surface sizing, post-drying, calendering, winding, and packaging to make baking base paper.

[0019] Surface sizing process: starch surface glue concentration is 13%, sizing amount is 35kg / ton ...

Embodiment 2

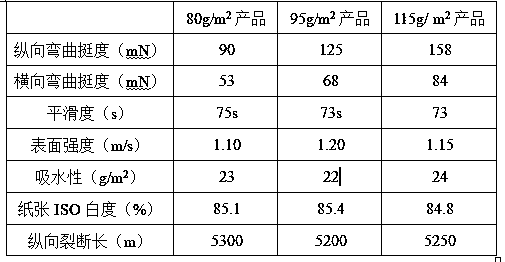

[0025] The purchased bleached softwood kraft pulp is beaten to 46°SR, and the bleached hardwood kraft pulp is beaten to 42°SR. In the beating process of NBKP and LBKP, 0.5kg / t of cellulase is added respectively; Seed pulp is prepared according to the proportions of 50% bleached softwood kraft pulp and 50% bleached hardwood kraft pulp. After mixing, the pulp is formulated to a concentration of 3.4%. The pulp is screened through the thick pulp sieve, and 10kg / is added in the seasoning section. t paper starch enhancer, add 4.0kg / t paper calcium sulfate at the same time, and then pour the pulp. In the puffing section, add wet strength agent with a dosage of 5.5kg / t paper, and then go through desanding and degassing, sizing, fine sieving, It is formed into baking base paper by drying, pressing, pre-drying, surface sizing, drying, calendering, winding, and packaging.

[0026] Surface sizing process: starch surface sizing agent concentration 12.5%, sizing amount 30kg / ton paper, water-r...

Embodiment 3

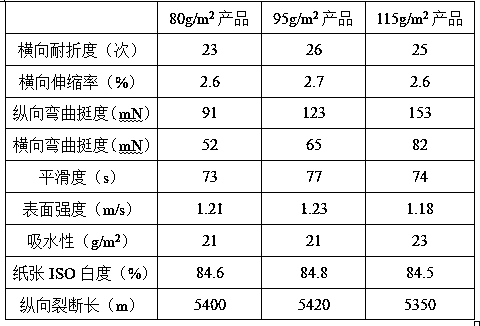

[0032] The purchased bleached softwood kraft pulp is beaten to 50°SR, and the bleached hardwood kraft pulp is beaten to 38°SR. In the beating process of NBKP and LBKP, 0.2kg / t of cellulase is added respectively; Seed pulp is prepared according to the ratio of 30% bleached softwood kraft pulp and 70% bleached hardwood kraft pulp. After mixing, the pulp is formulated into a slurry with a concentration of 3.0%. The pulp is screened through a thick pulp sieve, and 12kg / t paper starch is added as the seasoning. Reinforcer, add 6.0kg / t of paper calcium sulfate at the same time, and then flush. In the flushing section, add a wet strength agent with a dosage of 8kg / t of paper, and then go through de-sanding and degassing, sizing, fine sieving, online forming and dehydration. Pressing, pre-drying, surface sizing and then drying, calendering, coiling, and packaging are made into baking base paper.

[0033] Surface sizing process: starch surface glue concentration 12.5%, sizing amount 50kg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com