Preparation method of ultra-large-size titanium carbide nanosheet with wrinkle structure and application of nanosheet in electrochemical energy storage

A technology of ultra-large size and nano-sheets, applied in the application of electrochemical energy storage, the field of preparation of ultra-large-sized titanium carbide nano-sheets, can solve problems such as hindering electrolyte transmission, achieve strong operability, increase specific surface area, and increase channels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of ultra-large titanium carbide nanosheets with wrinkled structure

[0032] Step 1. Ultra-thin Ti 3 C 2 Preparation of nanosheets

[0033] (1) Add 1 g LiF to 20 mL 9 M HCl, stir magnetically until LiF is completely dissolved;

[0034] (2) To prevent local overheating, slowly add 1 g Ti 3 AlC 2 ;

[0035] (3) Put the mixture in the reaction kettle, at 60 o Under the condition of C, react for 72 h;

[0036] (4) Centrifuge the product (3500 rpm / 5 min), wash 6 times with deionized water, wash 2 times with ethanol, and dry in vacuum;

[0037] (5) Weigh 0.1 g of the dried product and disperse it in 10 mL of deionized water, and ultrasonicate for 4 h at 600 W;

[0038] (6) Centrifuge the sonicated product (3500 rpm, 1 h), and the upper liquid is the desired substance.

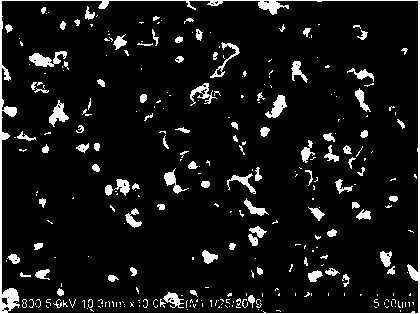

[0039] figure 1 Ultrathin Ti 3 C 2 SEM photographs of the nanosheets, figure 2 Ultrathin Ti 3 C 2 TEM photo of the nanosheets.

[0040] Step 2. Oversized Ti with wrinkled...

Embodiment 2

[0046] Embodiment two: Ti 3 C 2 Fabrication of Flexible Thin Film Electrodes

[0047] Supersized Ti with wrinkled structure 3 C 2 Ultrasonic dispersion of nanosheets is uniform, and Ti is prepared by vacuum filtration technology 3 C 2 film electrode and dried at room temperature for 6 h.

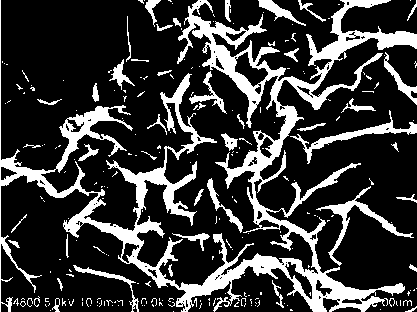

[0048] Figure 5 for Ti 3 C 2 The front SEM photograph of the flexible electrode, Figure 6 for Ti 3 C 2 Sectional SEM photographs of flexible electrodes.

Embodiment 3

[0049] Example 3: Ultra-thin Ti 3 C 2 Electrodes prepared from nanosheets and ultra-large Ti with wrinkled structure 3 C 2 Cyclic voltammetry test of electrodes prepared from nanosheets

[0050] 1. Working electrode: ultra-thin Ti 3 C 2 Electrode prepared from nanosheets (original size: 1.8 cm×0.8 cm; soaked size: 0.9 cm×0.8 cm, mass: 0.0035 g); reference electrode: Ag / AgCl; counter electrode: Pt sheet (1 cm×1 cm) ; Electrolyte: 0.5 M H 2 SO 4 ;CV potential window: -0.3 V~0.3 V; Immerse the thin film electrode in the electrolyte, let it stand for 10 min, and activate it until the curves completely overlap at the scan rate of 100 mV / s;

[0051] 2. Working electrode: oversized Ti with wrinkled structure 3 C 2 Electrode made of nanosheets (original size: 1.8 cm×0.8 cm; soaked size: 0.9 cm×0.8 cm, mass: 0.0035 g); reference electrode: Ag / AgCl; counter electrode: Pt sheet (1 cm×1 cm); Electrolyte: 0.5M H 2 SO 4 ;CV potential window: -0.3 V~0.3 V. Immerse the thin film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass specific capacitance | aaaaa | aaaaa |

| Mass specific capacitance | aaaaa | aaaaa |

| Mass specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com