Tellurium-doped MXene composite material and preparation method and application thereof

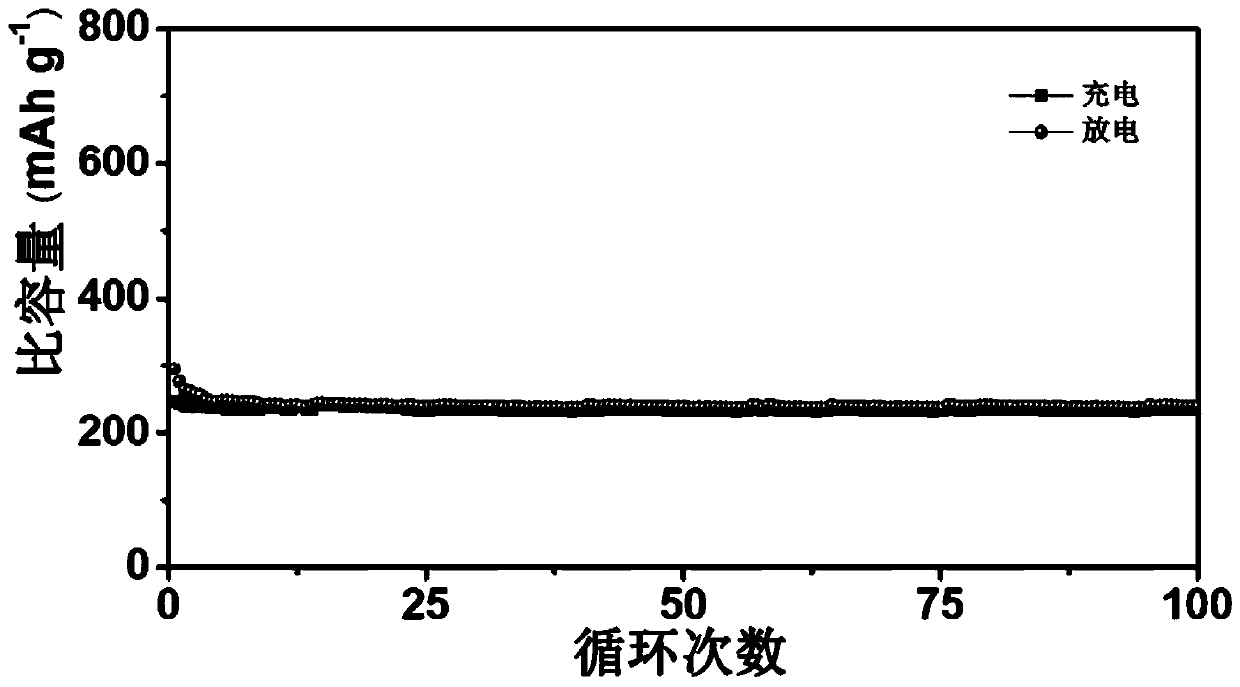

A composite material and tellurium source technology, which is applied in the preparation of tellurium-doped MXene composite materials and in the application field of potassium ion batteries, can solve the problems of unsatisfactory performance and achieve improved electrochemical performance, rich active sites, The effect of large lattice distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of tellurium-doped MXene composite material, comprising the following steps:

[0034] (1) Take 50mg MXene (Ti 3 C 2 T x ) and 0.5 mg of biphenyl ditellurium were added to ethanol, configured into a 1 mg / ml ethanol dispersion, and magnetically stirred for 1 hour;

[0035] (2) Move the dispersion obtained in step (1) to a reactor with a capacity of 100ml, seal it, place it in an oven, keep it warm at 100°C for 10 hours, and cool to room temperature;

[0036] (3) After the product obtained in step (2) was centrifuged for 5 minutes under the condition of 5000r / min with a centrifuge, it was washed with ultrapure water and absolute ethanol for 3 times and then moved to a vacuum drying oven; the drying temperature was 60°C. Drying time 5 hours;

[0037] (4) Place the product obtained in step (3) in a corundum ark, transfer it to a tube furnace, and under the protection of Ar gas, heat it to 300°C at a heating rate of 5°C / min, keep it warm for 3 hours a...

Embodiment 2

[0041]A preparation method of tellurium-doped MXene composite material, comprising the following steps:

[0042] (1) Take 1000mg MXene (Ti 3 C 2 T x ) and 500 mg of biphenyl ditellurium were added to ethanol, configured into a 50 mg / ml ethanol dispersion, and magnetically stirred for 3 hours;

[0043] (2) Move the dispersion obtained in step (1) to a reactor with a capacity of 50ml, seal it, place it in an oven, keep it warm at 150°C for 15 hours, and cool to room temperature;

[0044] (3) After the product obtained in step (2) was centrifuged for 5 minutes under the condition of 5000r / min with a centrifuge, it was washed with ultrapure water and absolute ethanol for 3 times and then moved to a vacuum drying oven; the drying temperature was 60°C. Drying time 15 hours;

[0045] (4) Place the product obtained in step (3) in a corundum ark, transfer it to a tube furnace, and under the protection of Ar gas, heat it to 300°C at a heating rate of 5°C / min, keep it warm for 3 hour...

Embodiment 3

[0049] A preparation method of tellurium-doped MXene composite material, comprising the following steps:

[0050] (1) Take 2000mg MXene (Ti 3 C 2 T x ) and 2000mg of sodium tellurite were added to ethanol, configured into a 100mg / ml ethanol dispersion, and magnetically stirred for 5 hours;

[0051] (2) Move the dispersion obtained in step (1) to a reactor with a capacity of 50ml, seal it, place it in an oven, keep it warm at 220°C for 24 hours, and cool to room temperature;

[0052] (3) After the product obtained in step (2) was centrifuged for 5 minutes under the condition of 5000r / min with a centrifuge, it was washed with ultrapure water and absolute ethanol for 3 times and then moved to a vacuum drying oven; the drying temperature was 60°C. Drying time 20 hours;

[0053] (4) Place the product obtained in step (3) in a corundum ark, transfer it to a tube furnace, and under the protection of Ar gas, heat it to 300°C at a heating rate of 5°C / min, keep it warm for 3 hours a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com