Alkaline manganese battery negative electrode additive containing wetting dispersant

A wetting and dispersing agent, alkaline manganese battery technology, applied in battery electrodes, aqueous electrolyte batteries, circuits, etc., can solve the problems of battery discharge capacity reduction, limited battery discharge capacity, and inability to provide moisture, so as to prevent uneven Settling, improving the effect of abnormal voltage drop and minimum average discharge time improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

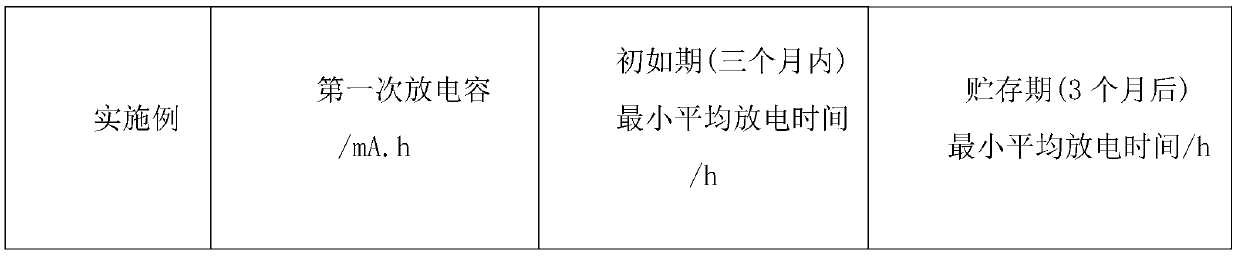

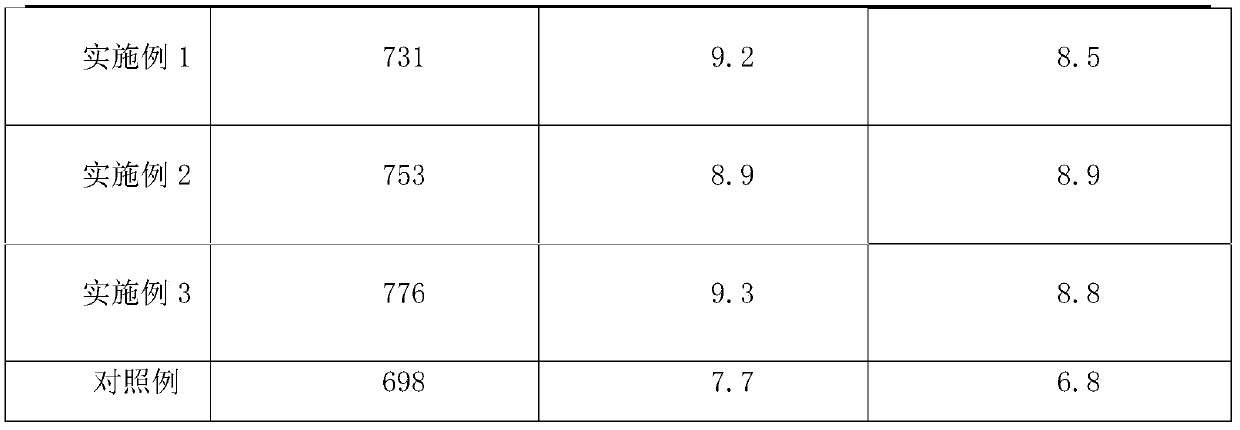

Examples

Embodiment 1

[0021] The invention provides an alkaline manganese battery negative electrode additive, each component and mass percentage are as follows:

[0022] Zinc powder 60%, zinc oxide 3%, polycarboxylate 0.1%, fatty alcohol polyoxyethylene ether 0.3%, dodecyltrimethylammonium bromide 0.1%, tallow amine polyoxyethylene ether 0.1%, hydroxide Indium 0.2%, cerium oxide 0.5%, methyl hydroxyethyl cellulose 0.1%, tin powder 0.4%, bismuth powder 0.2%, 9.2mol / L potassium hydroxide solution to make up to 100%.

Embodiment 2

[0024] The invention provides an alkaline manganese battery negative electrode additive, each component and mass percentage are as follows:

[0025] Zinc powder 65%, zinc oxide 1%, naphthalene sulfonate 0.2%, alkylphenol polyoxyethylene ether 0.3%, dodecyltrimethylammonium bromide 0.2%, octadecylamine polyoxyethylene ether 0.1%, Indium hydroxide 0.3%, cerium oxide 0.1%, methyl hydroxypropyl cellulose 0.2%, xanthan gum 0.1%, tin powder 0.1%, bismuth powder 0.1%, 9.2mol / L potassium hydroxide solution to make up to 100%.

Embodiment 3

[0027] The invention provides an alkaline manganese battery negative electrode additive, each component and its parts by weight are as follows:

[0028] Zinc powder 70%, zinc oxide 2%, polycarboxylate 0.1%, naphthalene sulfonate 0.2%, alkylphenol polyoxyethylene ether 0.8%, tallow amine polyoxyethylene ether 0.1%, octadecylamine polyoxyethylene ether 0.15%, indium hydroxide 0.25%, cerium oxide 0.3%, methyl hydroxyethyl cellulose 0.1%, xanthan gum 0.1%, tin powder 0.25%, bismuth powder 0.15%, 9.2mol / L potassium hydroxide solution to make up to 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com